23

IN

S

T

A

LLE

R

External Probe Kit

Installation and setting

The External Probe automatically manages the system delivery temperature according

to the external temperature, so that the user does not have to adjust it manually. This

function is also defined

"sliding temperature"

.

**

i.e. heating elements temperature. This adjustment does not have to be confused with ambient temperature (settable

on ambient thermostat or on remote control, but not on boiler) which does not depend from the first one.

Installation must be carried out by a qualified technician

following the instructions

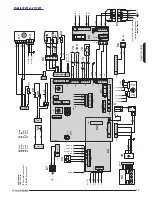

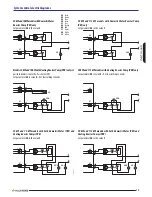

supplied with the kit. For connection to management board see "Boiler electric diagram:"

on page 16.

After having installed the external Probe, keys

and

described in the User

Section will not allow setting the delivery temperature any more, but the dispersion

coefficient

"kd"

, e.g. the influence that the external temperature, detected by the

probe, will have on the system delivery temperature, as shown in the following diagram.

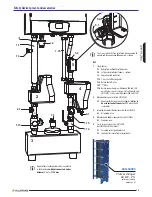

35

40

45

50

55

60

65

70

75

78

MAX

MIN

High temperature range 35÷78 °C

–20

t

ext

(°C)

–15

–10

–5

0

5

10

15

20

25 27

20

25

30

35

40

45

MAX

MIN

Low temperature range 20÷45 °C

(if available)

(kd=00)

kd=05

kd=01

kd=10

kd=15

kd=20

kd=25

kd=30

00177

ENG 00

the

kd

value must be adjusted according to the estimated quality of the

property thermal insulation . Its range of adjustment will be from 01 to 30:

the

highest values

are used when there is a

high thermal dispersion

and therefore

a

less efficient insulation

(and vice versa).

Given the great variety of property types, it is not possible to give precise

indications on the

kd

value to set.

a correct adjustment will have to be

evaluated case by case and will result in best comfort in all weather

conditions

which require heating, i.e. a quick achievement of ambient

temperature at cold climate conditions and absence of overheating at mild

climate.

external Probe Kit with optional remote control

If Remote Control was present, its

P04

parameter (remote ambient modulation type)

must be set on value

2

(modulating on external probe and on-off on ambient probe)

or

3

(modulating on both ambient and external probe) as described in

paragraph 5

of the

booklet supplied with the Remote Control Kit. Therefore, also the

kd

has to be set on this

last one (ref.

paragraph 8 .6

of the same booklet). On the Remote Control, only because

of a display difference, the

kd

range of adjustment will be

0.1...3.0

instead of 01...30.

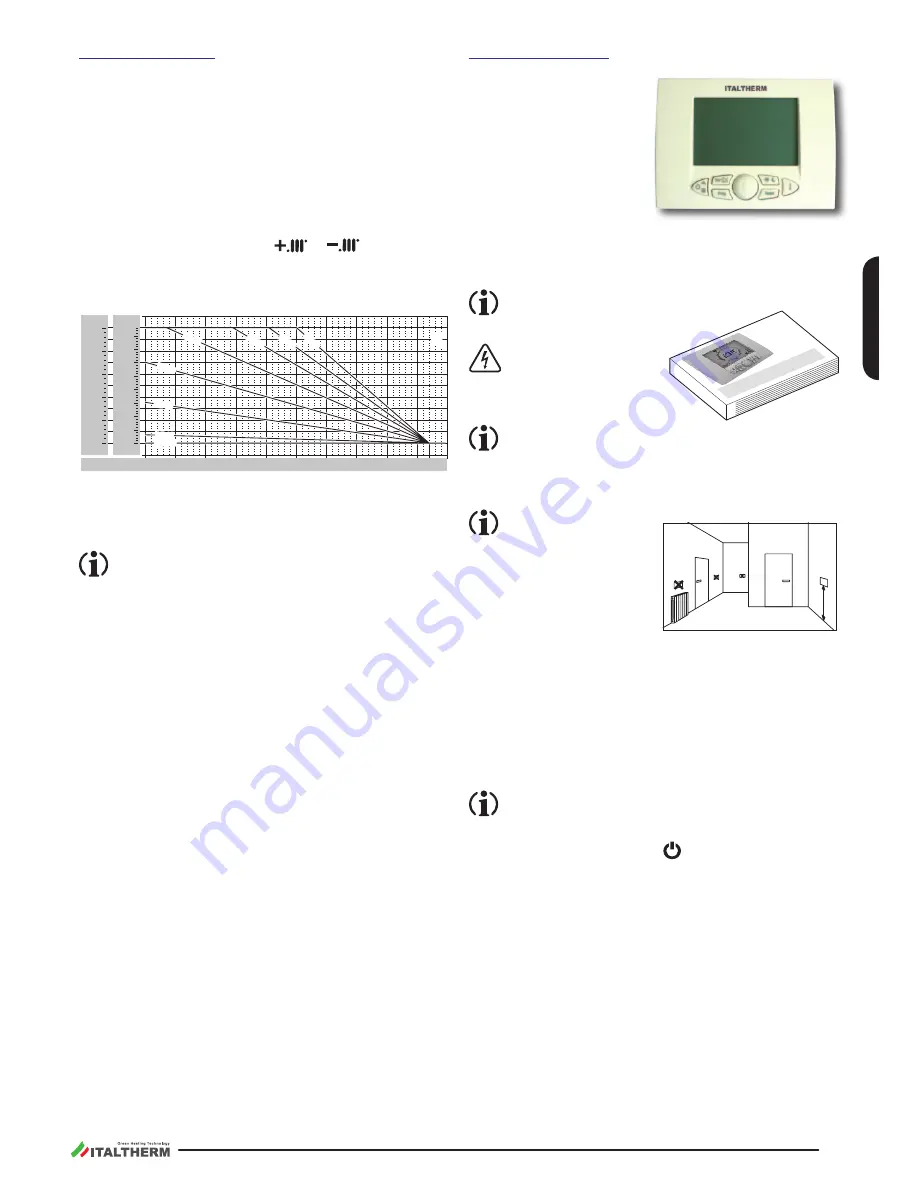

Remote Control Kit

The original Remote Control

is more

than just a chronothermostat:

it optimizes boiler operation

,

interfacing with the relevant electronics.

It incorporates a

complete weekly

climate programmer, easy to be set

and used

: to switch from programmed

to manual operation and vice versa it is

enough to press a key

. It responds to

all boiler controls

and provides the

Technician with

diagnostic information and further functions

. Easy to install, it is

connected in place of the Ambient Thermostat. It is powered by the boiler, in very low

tension and therefore

needs no batteries

.

Remove Remote Control from its box and

keep relevant instructions for use .

attach them to this instruction

booklet .

neither the remote control

nor the relevant cable coming

from the boiler must be

connected to the 230 V power

supply, for no reason .

In order to avoid malfunctions

caused by disturbances, Remote Control connections and other possible low

voltage connections must be kept separated from power supply system cables,

e.g. letting them pass through separate sheaths.

Cable maximum length must be less than 50 m.

The Remote Control must

be installed at a height of

approximately 1.5 m in a suitable

location for measuring ambient

temperature correctly, avoiding

installation in recess or corners,

behind doors or curtains, and

install away from heat sources,

direct sunlight and water sprays.

1 .

Make sure that boiler is not electrically powered;

2 .

install device as described in

paragraph 4

of the booklet supplied with the Kit;

3 .

connect Remote Control connections to the "Ambient Thermostat - Remote Control"

cable coming from the boiler using a suitable bipolar terminal. See also "Boiler

electric diagram:" on page 16;

Note:

Remote Control connection has no polarity.

Check device correct operation. Electronics automatically recognises it (otherwise

alarm

E31

, already described in par. "Alarms - boiler shut-down" on page

33 is triggered

provided that

:

•

on boiler control panel, through key

,

Summer

mode is always selected.

From now onwards, boiler operation modes (also OFF) will be selected only by

the Remote Control;

•

board is set as in "Settings on electronic board" on page 33.

4 .

the boiler displays the message "

re .on

".

00088a_00

NO

NO

NO

SI

1.5 mt

CON

TRO

LLO

RE

MO

TO

EA

SY

RE

MO

TE

MA

NUA

LE

DI

IST

RUZ

ION

I

Summary of Contents for Time Power 115 K

Page 42: ...42 Notes...

Page 43: ...43 Notes...