27

IN

S

T

A

LLE

R

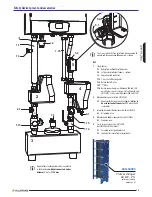

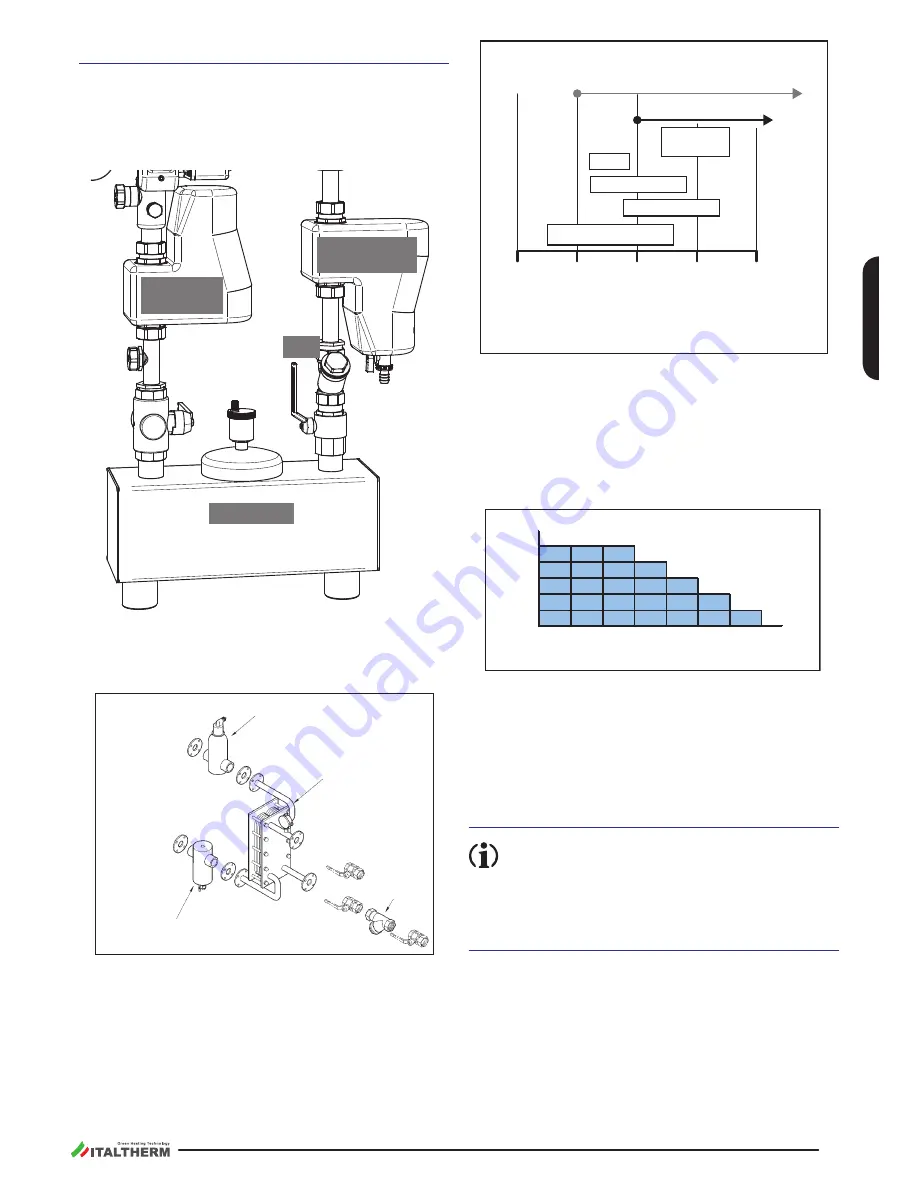

accessories to Be Installed on the System

Before switching the boiler on, let water circulate (with boiler off) for at least 2 hours in

order to eliminate any impurity from the system through the micro-air bubbles separator

and micro impurity separator. During this last phase, open the drain cock fitted onto the

micro impurity separator at regular intervals, so as to eliminate any deposit. (Repeat this

operation also during the first heating phase).

MIcro-aIr BuBBle

SeParator

fIlter

Balancer

MIcro IMPurItIeS

SeParator

As an alternative to these parts, it is also possible to make use of plate exchangers, hav-

ing the characteristics required by the system currently in use. It is always necessary, in

any case, to install at least one system for micro-air bubble separation on the exchang-

er boiler delivery side. System filling water must always be treated as described above.

MICRO-AIR BUBBLE SEPARATOR

PLATE EXCHANGER

FILTER

MICRO IMPURITIES SEPARATOR

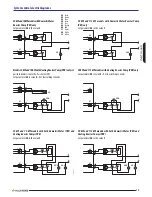

operating range of micro-impurities/dirt separator

0.001

1µm

0.010

0.100

1.000

1,000 µm

10.000

impurities visible to the naked eye

operating range of standard filters

It is just those particles in the range of 5-10 µm

that cause the worst problems.

processing

residues

hair

rust

sand

lodestone

BENEFITS

•

Impurity discharge while the system is working.

•

There is no need to install check valves or bypass circuits.

•

No obstructions, no load losses.

•

Also microscopic particles (up to 5 µm) are filtered.

•

Servicing in just 5 seconds.

Ø

1"1/4

1"1/2

DN050

DN065

DN080

1,25

2

3,7

5

8

15

20

m

3

/h

PORTATA MASSIMA

MAXIMUM FLOW

IMPURITY SEPARATORS

1. Define the diameter in the assembling point

2. Define flow in the assembling point (cu.m/h)

3. See the table to define the suitable model

circulating pump recommendations

Before switching on the boiler,

make sure that the circulating pump is

not blocked

due to inactivity: in the middle of the cap there is a hole (should

there be a cap, remove it) that gives access to the rotor shaft;

push and turn

it using a suitable tool

, usually a "Phillips" screwdriver.

filling the Water circuit

Once all system connections have been made, the circuit can be filled. For perfect boiler

filling, this operation should be carried out with extreme care, strictly following these steps:

- open radiator air purging valves;

- open heating system filling valve, and wait for all the air to be bled out of the radia-

tors;

- make sure that boiler automatic air purging valve works properly;

- close radiator valves as soon as water starts to come out;

Summary of Contents for Time Power 115 K

Page 42: ...42 Notes...

Page 43: ...43 Notes...