5

U

T

E

N

T

E

US

E

R

Multifunction display

…

Day of the week

Displayed: during programming, during standard operation if programming is activated.

00147 A 00

heating - Winter mode

If it flashes, it indicates that the boiler is working in heating mode.

heating request area

It indicates from which area (main "1", secondary "2" or both) heating request comes from.

Domestic water programming time frame

During domestic water programming (see "Setting of the program of boiler no. 3 - User" on page 7)

it indicates which time frame, between the two available ones, is being programmed

available solar system

(if connected to the boiler through optional Solar Board)

When boiler is heating solar storage, symbol flashes.

Burner working

Quick boiler preparation

It indicates that the quick boiler preparation function has been activated. It flashes when the boiler is carrying out the quick preparation.

Domestic water - storage heating

It indicates that the boiler is enabled for domestic water heating. If it flashes, it indicates that the boiler is heating.

heating temperature

, in °C (2-digits indicator under the symbol

)

It usually indicates the

delivery temperature

, i.e. the temperature of the liquid circulating in the heating system, coming out of the boiler.

During heating temperature adjustment (through keys

and

)

it displays the set value

.

It is displayed when the boiler is shut down or there is an error which can be reset by the User. See "Alarms - boiler shut-down" on page 33 for error identification

and for actions to be undertaken according to each different case.

It is displayed when the boiler has a fault or there is an error which can be reset by the Technician. The user can refer to "Alarms - boiler shut-down" on page 33

for further information and any possible actions to be undertaken according to each different case.

Domestic water temperature

, in °C (2-digits indicator under the symbol

)

It indicates the domestic water storage set temperature.

It indicates that the boiler preparation function is active in a programmed mode.

It indicates, with the symbol , if at the present moment the boiler preparation function is set to

ON

or

OFF

.

It is displayed when the two digits on its right indicate the boiler operating power. This information is displayed only while menu

is used (see "Menu INFO"

on page 8).

These four digits, in the display lower central area, show different information, e.g. during normal operation: present time, heating system pressure, temperature

measured by external probe (in this last case, only if the symbol

is visible). While menu

is used, other data are displayed. For the setting of the dimension

to normally show, see"4-digits display setting" on page 7; for other relevant information see "Menu INFO" on page 8.

When boiler is electrically powered, but in

OFF

mode, this indicator shows the writing

OFF

.

They show the type of displayed data item on their left. If they are both switched off, the data item is either a time or expressed in a unit of measurement other

than Bar or °C.

It indicates that the external temperature probe (optional) is connected to the boiler.

Note:

in this case, system temperature is automatically adjusted and the use of keys

and

is different: for details refer to the kit documentation

and to paragraph "External Probe Kit" on page 23.

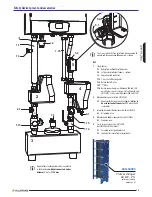

Boiler external commands

Outside the boiler, conveniently positioned in the property (usually by the installer or

by the person in charge of installing the electrical system), there are two devices that

must be used by the user. Their presence and features are prescribed by rules in force:

omnipolar switch:

it is usually positioned near the boiler and must completely isolate

the boiler from domestic mains supply. It must be used each time the boiler needs to

be electrically powered, or when power supply of the equipment has to be switched

off, e.g. in case of long inactivity periods (see "Safety mode" on page 9) or in

some alarm cases (see "Alarms - boiler shut-down" on page 33).

ambient thermostat:

it electrically commands to the boiler the activation or the

switching off of the heating system, in order to maintain ambient temperature

(detected by one of its sensors) approximately at a value set by the user. Current

regulations describe its positioning, temperature limits within which the user can

adjust it and the switching on and off periods of the heating system.

Note:

ITALTHERM offers an advanced chronothermostat, with weekly programming at

multi-level temperature and other innovative functions. Furthermore, a version with

radio frequency connection

and a version with

GSM command

are available.

Summary of Contents for Time Power 115 K

Page 42: ...42 Notes...

Page 43: ...43 Notes...