6

ENGLISH

FRANÇAIS

FRANÇAIS

ENGLISH

6

ENGLISH

FRANÇAIS

FRANÇAIS

ENGLISH

correct specifications. With the air compressor on level surface, the oil level

should be at the red dot on the oil level sight glass.

=

If oil level is low, remove oil fill plug/breather cap, add enough oil to bring level

to the red dot. Do not over-fill.

=

Replace oil fill plug before starting compressor.

BEFORE OPERATING COMPRESSOR:

=

Check and ensure that oil fill plug/breather cap (27) is installed with o-ring (27a)

into crankcase (28).

=

Check that nuts and bolts are all snug.

=

Check the quantity and quality of oil (see compressor lubrication, above).

COMPRESSOR INITIAL BREAK-IN

1. Open

Drain cock

() to permit air to escape, so no air pressure builds up in

the air tank.

2. Plug power supply cord into correct power source.

3. Run the compressor in this no-load condition for 20 to 30 minutes to lubricate

the bearings and pistons.

4. Close the air tank drain cock.

5. Your compressor is now ready for use.

6. After 2 weeks, tighten all nuts and bolts, including head bolts.

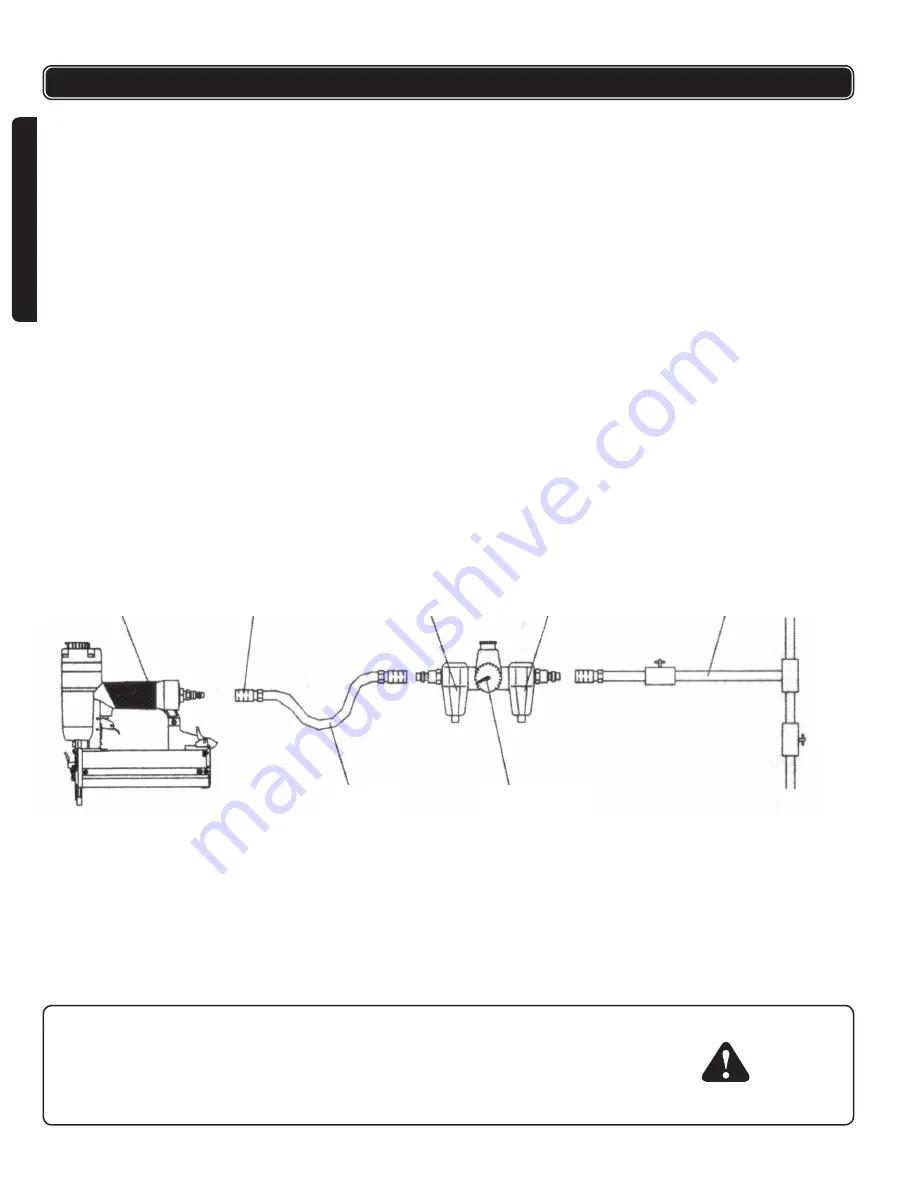

AIR SYSTEM

=

The brad nailer/stapler is designed to operate on clean, dry, compressed air,

regulated at 60-100 psi / 413 to 690 kPa / 4.13 to 6.9 bar. The preferred sys

-

tem would include a filter, a pressure regulator, and an automatic oiler located

as close to the tool as possible (within 15 feet / 5 meters is ideal). Do not use

bottled air or gases. Please see figure below:

=

All compressed air contains moisture and other contaminants that can harm the

internal components of the tool. An air line filter will remove most of these and

significantly prolong the life of the tool. Ensure the in-line oiler has sufficient

oil. If an in-line oiler is not available, place 2 drops of oil into the tool’s air inlet

at the beginning of each workday. More than this will be expelled from the

tool’s exhaust during firing.

=

Air Fitting: The nailer should be equipped with a 1/4" NPT male plug for a ‘quick

connector’. To prevent accidental cycling even though disconnected, the tool

must always be connected to the air supply in such a way that all air pressure

in it is released when the coupling is disconnected.

CAUTION:

=

All air line components (including hoses, pipe, connectors, filters, & regulators,

etc.) must be rated for a minimum working pressure of 150 psi / 1034 kPa /

10.3 bar or 150% of the maximum system pressure, whichever is greater.

=

Disconnect the tool from the air supply before performing maintenance, clear-

ing a jammed fastener, leaving the work area, moving the tool to another loca-

tion, or handing it to another person.

Air Hose

Nailer/Stapler

Quick Connector

Oiler

Filter

Air Supply

Regulator

SETUP & OPERATION