6

ENGLISH

FRANÇAIS

FRANÇAIS

ENGLISH

6

ENGLISH

FRANÇAIS

FRANÇAIS

ENGLISH

CONNECTING THE TOOL

1. Turn the compressor on.

2. Set the regulator to proper pressure for the size for the size and type of

fasteners being used.

3. After reading and understanding this entire manual, connect tool to air supply.

CAUTION:

=

Keep the tool pointed away from yourself and others at all times

.

=

Do not load fasteners with air connected, safety or trigger depressed.

=

Always wear approved safety glasses and hearing protection when preparing

or operating this tool.

=

Never use a tool that leaks air or needs repair.

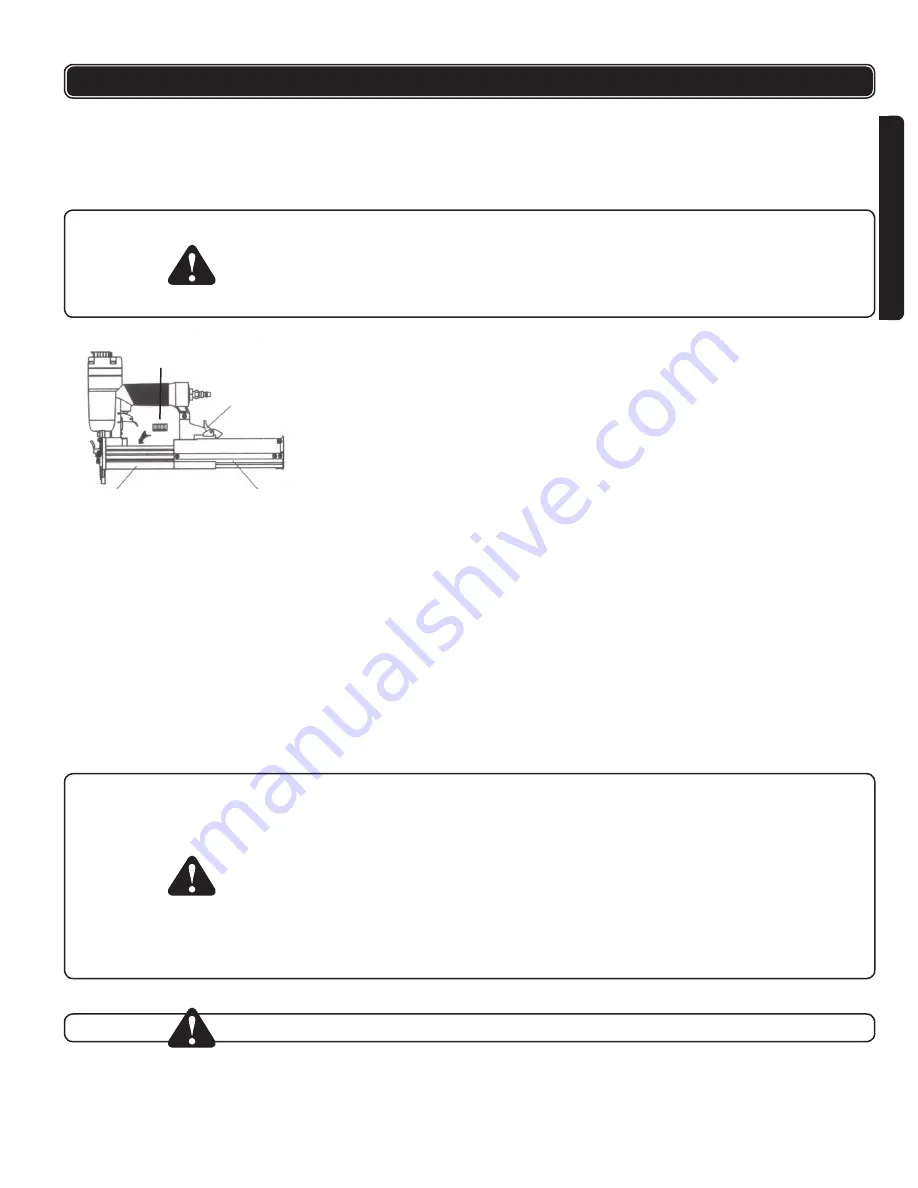

LOADING THE FASTENERS

1. Disconnect the tool from the air supply. Do not load or adjust the tool if it is

connected to the air supply.

2. Depress the LOCK (61) to release the MOVABLE MAGAZINE (57) and pull the

magazine out fully as shown.

3. Place a full stick of the desired type and size of fasteners on the FIXED

MAGAZINE (53). Up to 100 fasteners can be loaded in the magazine.

4. Push the MOVABLE MAGAZINE UNIT (57) forward until the LOCK (61) clicks

and locks it.

. The tool is ready to operate.

OPERATING THE TOOL

1. The depth to which a fastener is driven is determined by the depth adjustment

wheel below the trigger and by supplied air pressure. Test fire a fastener into a

sample of the material you will be working on and check depth.

2. Make sure the air pressure is within the limits mentioned in SPECIFICATIONS.

3. Hold the BODY (24) and press SAFETY BRACKET ASSEMBLY (29) against

the work surface, being sure the tool is perpendicular to the surface.

4. Gently squeeze the TRIGGER (39) to drive the fastener.

5. Lift the tool off the work surface.

6. If a change is desired, first adjust the wheel, turning it to the left for greater

depth and to the right for less.

7. Further adjustment can be had by adjusting the compressor regulator to supply

air at a higher or lower pressure. Test fire another fastener and check depth

again.

8. Continue to adjust as necessary.

CAUTION:

=

Keep tool pointed in a safe direction at all times.

=

Never attempt to drive fasteners into materials too hard to penetrate, or at too

steep an angle, or too near the edge of the workpiece. The fastener can rico-

chet causing personal injury.

=

Disconnect tool from air supply before doing any disassembly, maintenance,

clearing a jammmed fastener, leaving the work area, moving the tool to another

location, or handing the tool to another person.

=

Clean and inspect the tool daily. Carefully check for proper operation of trigger

and safety mechanism. Do not use the tool unless both the trigger and the

safety mechanism are functional, or if the tool is leaking air or needs any other

repair.

CLEARING A JAMMED FASTENER

1.

CAUTION:

Disconnect the tool from the air supply.

2. Depress the LOCK (61) to release the MOVABLE MAGAZINE UNIT (57) and pull

the magazine out fully.

3. Remove any remaining fasteners from the tool.

4. Open the LATCH ASSEMBLY (45) and swing open the FRONT PLATE (47).

SETUP & OPERATION

Fixed Magazine

Movable Magazine

Lock

Fasteners