11

MQH 11/08

Check that the condensing and evaporation temperatu-

res, during operation at high and low pressure detected

by the pressure gauges of the refrigerant, are within the

following range:

(on the units not provided with HP/LP pressure gauges for

the refrigerant, connect a pressure gauge to the

Schreader valves on the refrigeration circuit).

2.5

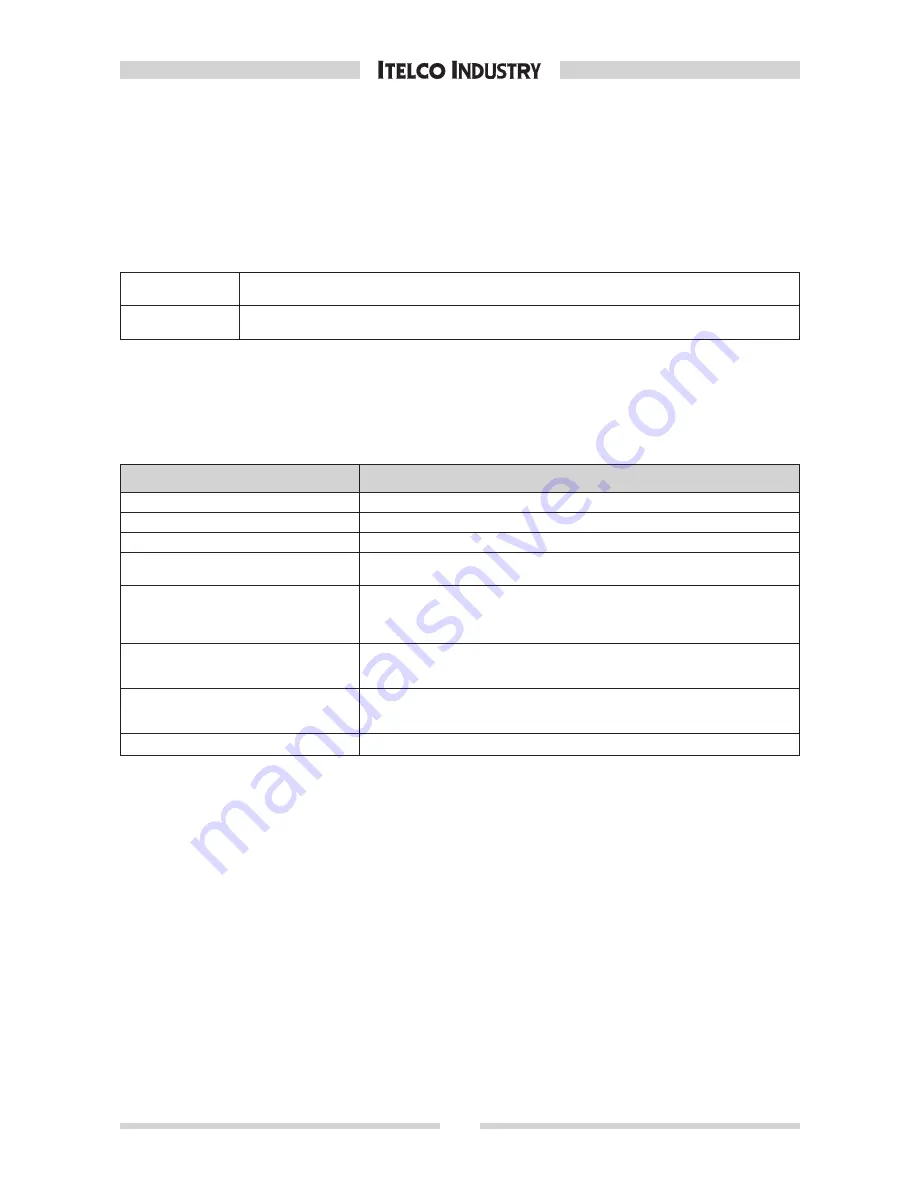

SYSTEM DIAGNOSTICS AND OPERATION AT FAULT CONDITIONS

FAULT

RESPONSE

LWT sensor failure

If in cooling then stop machine

EWT sensor failure

Use EWT = LWT + 5

EWT & LWT failure together

Stop machine

OAT sensor failure

Use OAT = 35 (cooling) – 8 (heating).

Variable speed in heating always in maximum speed

CP sensor failure

Fans to max speed when OAT > 20 °C

Fans to low speed when 15 °C < OAT < 20 °C

If OAT < 15 °C, stop the unit in cooling only Disable vs.

In heating, end defrost only with OCT > OCTe or Td > Tde

EP sensor failure

In cooling mode, correct CSPT to CSPT > FP + 7

In heating, if OAT < 10 °C start defrost routine every 40 mins and end

defrost routine after 90 sec.

OCT failure or CP & OCT failure

In heating, if OAT < 10 °C start defrost routine every 40 mins and end

defrost routine after 90 sec.

Variable speed in cooling: always in maximum speed.

EP & CP failure

Stop the unit

HP

Approx. 13 to 18 °C above the temperature of the air entering the condenser,

for R 410a units.

LP side

Approx. the difference between the temperature of the leaving water and saturated evaporating

temperature must be in the 2 - 4 °C for R 410a units.