3

MQH 11/08

1.2

GENERAL SPECIFICATIONS

• The control box is in compliance with European cur-

rent standard about emissions and immunity (e.m.c ).

• The miniCAC control board mounted in a IP20 plastic

case. The plastic is in compliance with UL94V0.

• Flash memory is used to store the program, enable re-

download via 10 bit A/D converter in factory and at

site.

• During power failure with a duration more then 40

msec, the control goes off and will random restart after

power comes back according the dip 5 position.

1.3

COMPATIBILITY WITH OTHER PRODUCTS AND SYSTEMS

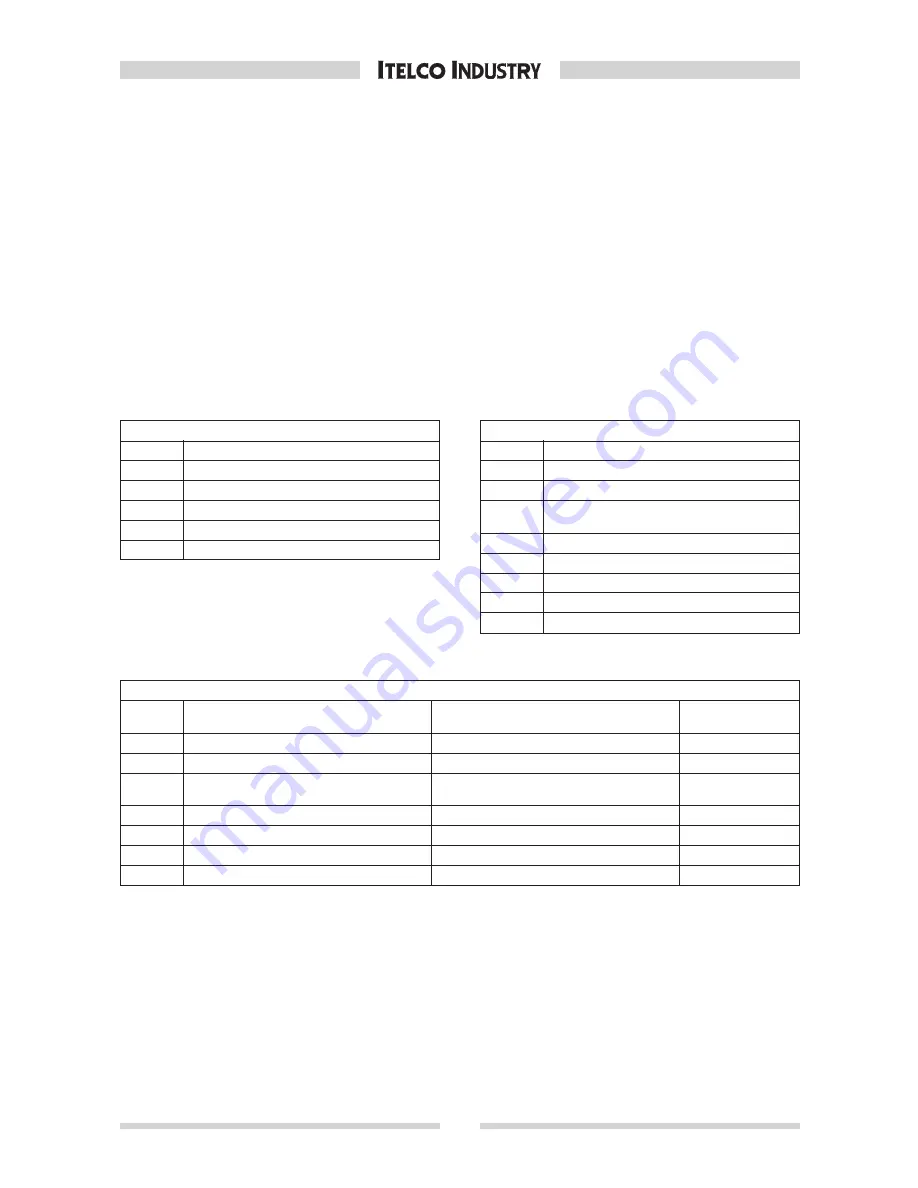

1.3.1 ELECTRICAL INTERFACES

Analogue Input

N°

Type

B1

NTC

B2

NTC

B3

NTC

B4

NTC/ratio

B5

NTC/ratio

Digital output

N°

Chiller

Type of relay

Type

(AC motor rating)

1C-O

Compressor

2A @ 230Vac

N.A

2C-O

Fan high speed or 2nd comp

4A @ 230Vac

N.A

3C-O

Fans motor or low speed

See note 1

TRIAC

(see note 1)

4C-O

Antifreeze heater

2A @ 230Vac

N.A

5C-O

Reversing valve

2A @ 230Vac

N.A

6C-O

Pump

4A @ 230Vac

N.A

7C-O

Unit alarm relay

2A @ 230Vac

N.A

Digital Input

N°

Chiller

ID1

Remote Unit Start/Stop

ID2

Cooling/Heating mode selection

ID3

Fan motor overload

(or 2nd compressor protection)

ID4

Compressor motor protection

ID5

Flow switch - Water diff. pressure switch

ID6

Low pressure switch

ID7

High pressure switch

ID8

Night Mode/Second setpoint