PM605KT/PM605KT-B Technical documentation

18

5.

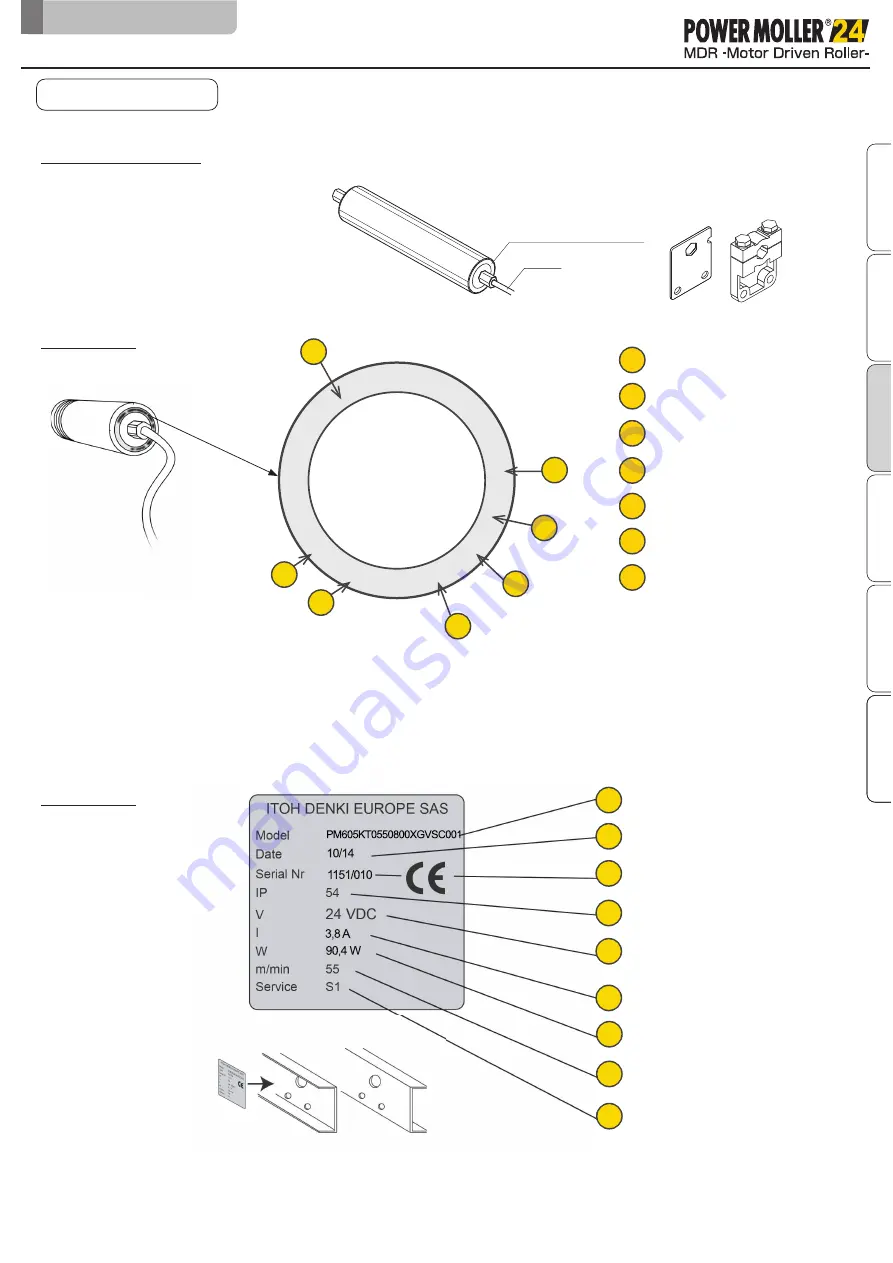

Check product

Checking the model

Open the package, and verify the product part number matches what you ordered.

MDR

Check product

Mounting bracket

(See Page 19)

Location of

part number indication

Cable

Safety precautions

Preparation Before Installation

Check product

Installation

Maintenance

Appendix

Original notice - A1.1

Round label

IT

O

H

D

E

N

K

I P

M

60

5K

T

0

55

0800

X

V

0S

C0

01

1

0/

1

4

11

5

1

/

0

1

0

IP

5

42

4

VD

C

5

5m

/m

n

S

1

1

2

3

4

5

6

7

1

2

3

4

5

6

7

Product reference number

Month and year of shipment

Serial number

Protection index

Power supply

Speed

Operation

Square label

1

2

3

4

5

6

7

8

Product reference number

Month and year of shipment

Serial number

Protection index

Power supply

Nominal intensity

Absorbed power

Speed

Operation

9