8

ENGLISH

IMPORTANT SAFETY INSTRUCTIONS:

·

This"Instructionmanual"hastobekeptontheplace,whichcanbeeasyreached

·

The regulator has to be used only for dry and clean gases Never use with oxygen: risk of

explosion

·

Thenationalnormsandstandardsaboutinstallation,start-upandmaintenanceofthedevices

andgasinstallationshavetobestrictlyrespected

·

Thehandlingwiththedevicehastobedonecarefully,speciallybytheinstallationworksThe

pickuphastobemadebyusingthestretchereyesorbelts

·

Thedeviceshouldbeexaminedbeforetheinstallationforpossibletransportdamagesandbe

mountedonlyifitisinperfectstatePossiblelacquerdamageshouldbeimprovedThesealing

surfacesofthethreadedconnectionsorflangesmustbedamage-freeandclean

·

Forreadingoffthedeviceanditsservingaresufficientlyspacetodesignate

·

Fortheprotectionofthedeviceisrecommendabletoinstallafilter

·

Thedeviceistobeinstalledinsuchawaythatitisnotimpairedinitsfunctionbyotherinstalla-

tioncomponents

·

Theregulatorhastobemountedinthepipelinewithoutanytension

·

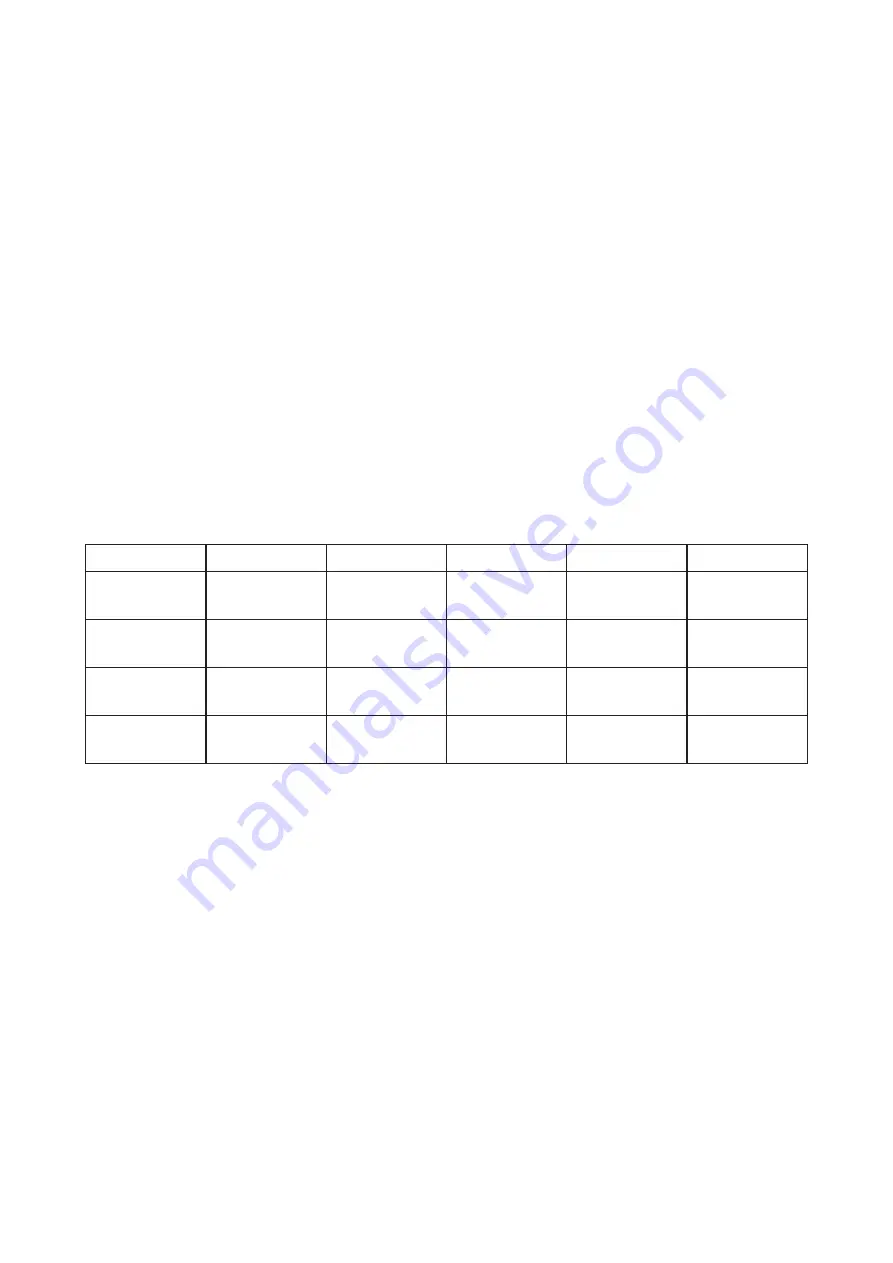

Thementionedbelowtorque'svaluesforscrewsmustberespectedbytightenoftheflanged

connections:

·

Thesetorque'svaluesarementionedperscrewandarevalidformetalsoftmaterialgaskets

(specifiedask

0

xK

D

=45b

D

undk

1

=2,2b

D

)Othergasketscanrequireanothertorque'svalues

·

Thescrewsusedfortheflangeconnectionmustbeaccordingtotheflangesizeandmustbe

adaptedtothetemperaturerangeoftheregulatorPleasetightenthescrewscrosswise

·

After the installation works are completed, the tightness of the connections (threaded or

flanged)mustbecheckedwithappropriatemeans

·

Theoperatingconditionsindicatedonthenameplatesmustberespected;ifnecessaryappro-

priatesafetydeviceshavetobedesignated

·

RepairsofthedeviceareallowedtobemadeonlybytrainedorqualifiedpersonalAfterwards

atightnesstestwith11XPSmustbeperformedWhenchangingpressurecontainingparts

theircompliancewithPEDmustbeassuredAfterGuaranteeonlywithrepairbyActaris

·

Thedevicehastoberegularlyexaminedforcorrosiondangerintheinteriorandexternalarea

andbetakenfromuseifnoticeablecorrosionisdiscovered

DN25

DN40

DN50

DN80

DN100

PN16

35Nm

(M12)

85Nm

(M16)

85Nm

(M16)

85Nm

(M16)

85Nm

(M16)

ANSI150

55Nm

(M14)

55Nm

(M14)

85Nm

(M16)

85Nm

(M16)

85Nm

(M16)

PN25

35Nm

(M12)

85Nm

(M16)

85Nm

(M16)

85Nm

(M16)

170Nm

(M20)

ANSI300

120Nm

(M16,88)

–

120Nm

(M16,88)

200Nm

(M20,88)

200Nm

(M20,88)