Page 10

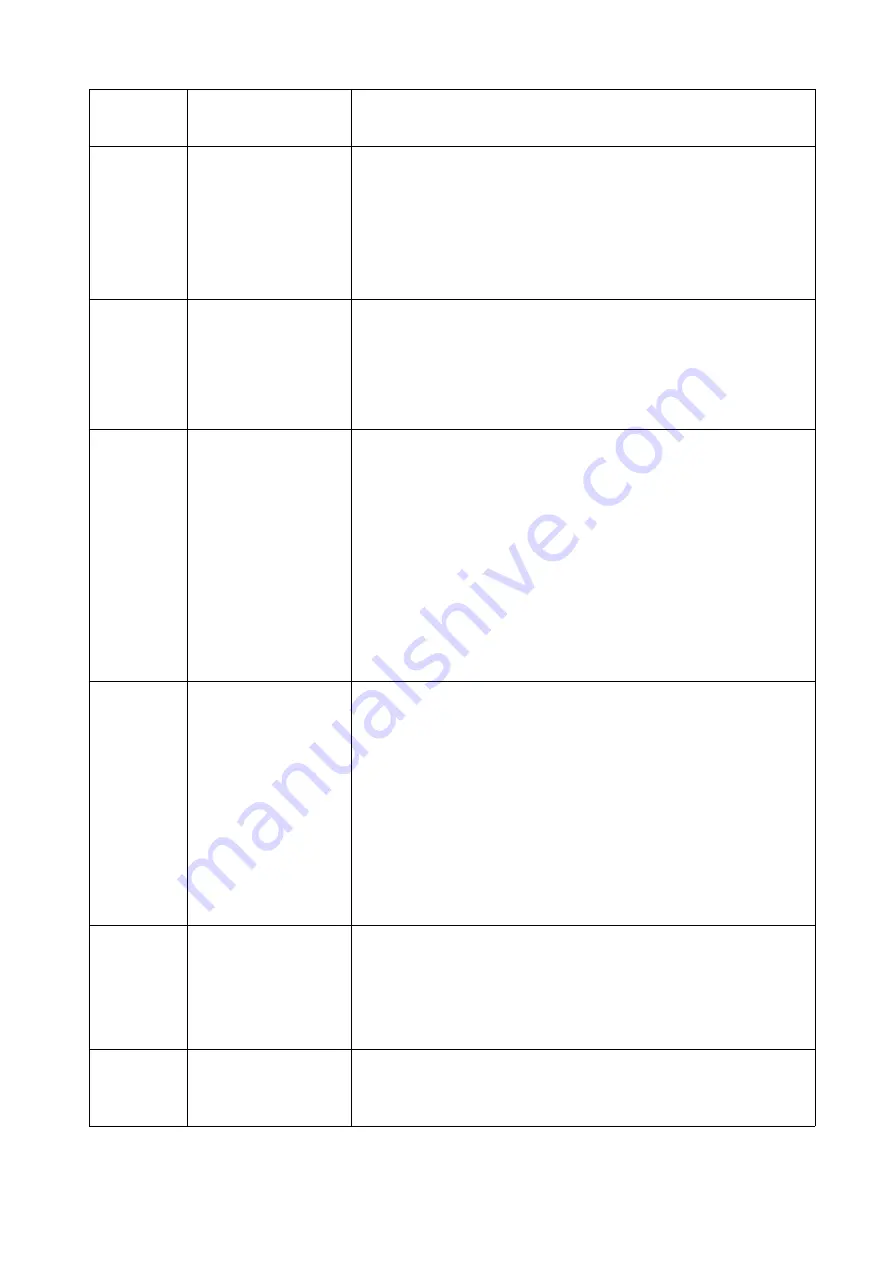

6.1 Error code and trouble-shooting

Error

Code

Error Description

Trouble-shooting

E1

Communication error: The

communication between the

lower control PCB and the

console is abnormal after

power-on.

Lower control PCB stops working to enter the error state. Can not turn on the treadmill.

Console displays the error code and the buzzer beeps 3 times.

Possible cause: The communication between the lower PCB and the console is blocked.

Check each cables’ connection areas to ensure that each cable is fully well inserted.

Check if the cable is damaged and replace it if damaged.

E2

Indicates that the controller

PCB did not detect the

voltage above the motor.

Possible cause: check whether the motor line is connected, reconnect the motor line,

check whether the controller PCB has odor, replace the motor;

E3

Speed sensor has no signal:

controller PCB has voltage

output to DC motor, but can

not receive motor speed

feedback for more than 3

seconds.

1. Check if the motor line is firmly connected to controller.

2. Shutdown into the error state, console buzzer beeps 9 times, at the same time console

displays error code, the other area does not show message. Maintain error state after

about 10 seconds into standby state, can restart.

Possible cause: in 3 seconds without detecting the speed sensor signal, check if sensor

plug is not plugged in or damaged, plug it or replace the sensor.

3. Shutdown into the error state, console buzzer beeps 9 times, at the same time console

displays error code, the other area does not show message. If it returns to normal after

shutdown, you can enter standby state, normally can start.

E5

Overcurrent protection: in

operation, the DC motor

current is more than 3

seconds longer than the rated

current.

Shutdown into the error state, console buzzer beeps 9 times, at the same time console

displays error code, the other area does not show message. Maintain error state after

about 10 seconds into standby state, can restart.

Possible causes: over rated load leads to excessive current, system self-protection, or a

part of the treadmill is stuck, resulting in the motor can not rotate, overload, excessive

current, the system self-protection; adjust the treadmill to run again. Or, please check if the

motor is running with overcurrent sound or if there is charred smell, to replace the motor, or

to check whether the controller PCB is charred, to replace the controller PCB, or to check

whether the power supply voltage specifications are not in accordance with or too low.

Re-test under the correct voltage specifications.

E6

Flameproof

protection:

abnormal

power

supply

voltage or abnormal motor

cause damage to drive motor

circuit.

Possible causes: check if the power supply voltage is less than 50% of the normal voltage,

please use the correct voltage specification to re-test; check the controller PCB for odour,

replace the controller PCB; check whether the motor line is connected, reconnect the

motor line.

E7

Indicates that the console did

not detect a security lock

signal

Magnetron damage, Check if magnetron installation position is correct, if magnets are well

placed.