PS200 Configuration & Operation Guide

OPTIONS & FEATURES

Page 99

setpoint. The smaller the integral time the faster the speed adjustments are made. If the integral time is set too short

speed oscillations may occur, if set too long a prolonged time period is likely prior to achieving the setpoint value.

Parameter

Name

Value/Range

Notes

13.04

I - Time

0-320 Sec

Pressure

[default]

- 0.75

Flow

[default]

- 1.75

DP / Flow [Quadratic] - 3.0

Level & Temp

[default]

- 0.75

RECOMMENDED GUIDELINES

Although there is no tuning procedure that will give optimum results for every system, there are certain guidelines

that will facilitate the tuning process in the event the default settings require adjustment. The following figures

show both normally tuned systems and improperly tuned systems. The first two figures “Normally Tuned” and

“Tuned” show examples of properly tuned systems. Note the second figure, “Tuned” has a better dynamic

response then the first system, but at the expense of a small overshoot in the setpoint. The last two figures show

examples of poorly tuned systems that result in an unstable undesirable response.

-

Normally the default settings for FAST ACCEL and FAST DECEL do not require adjustment unless the drive

response during ramp up or ramp down to the setpoint is unsatisfactory for the particular process.

-

If the default settings result in an unsatisfactory drive response the following rules of thumb can be applied:

x

If rapid oscillations occur about the setpoint try increasing the value of the integral time (parameter

13.04) first. If the oscillations still continue or the time to drop to the setpoint is too long the

proportional gain (parameter 13.03) should also be lowered.

x

If the amount of overshoot is unacceptable increase the integral time and lower the proportional gain.

x

If there is a low offset in the setpoint the proportional gain should be increased.

x

If there is a lengthy time period before achieving the final setpoint the integral time should be

decreased.

x

In level control applications if speed oscillations occur increase the integral time.

-

Once the tuning is fairly close several iterations between the values of proportional gain and integral time

may be required to obtain optimum results.

-

It is important to note that the final values for the proportional gain and integral time should be determined

not only for system changes but also for startup conditions.

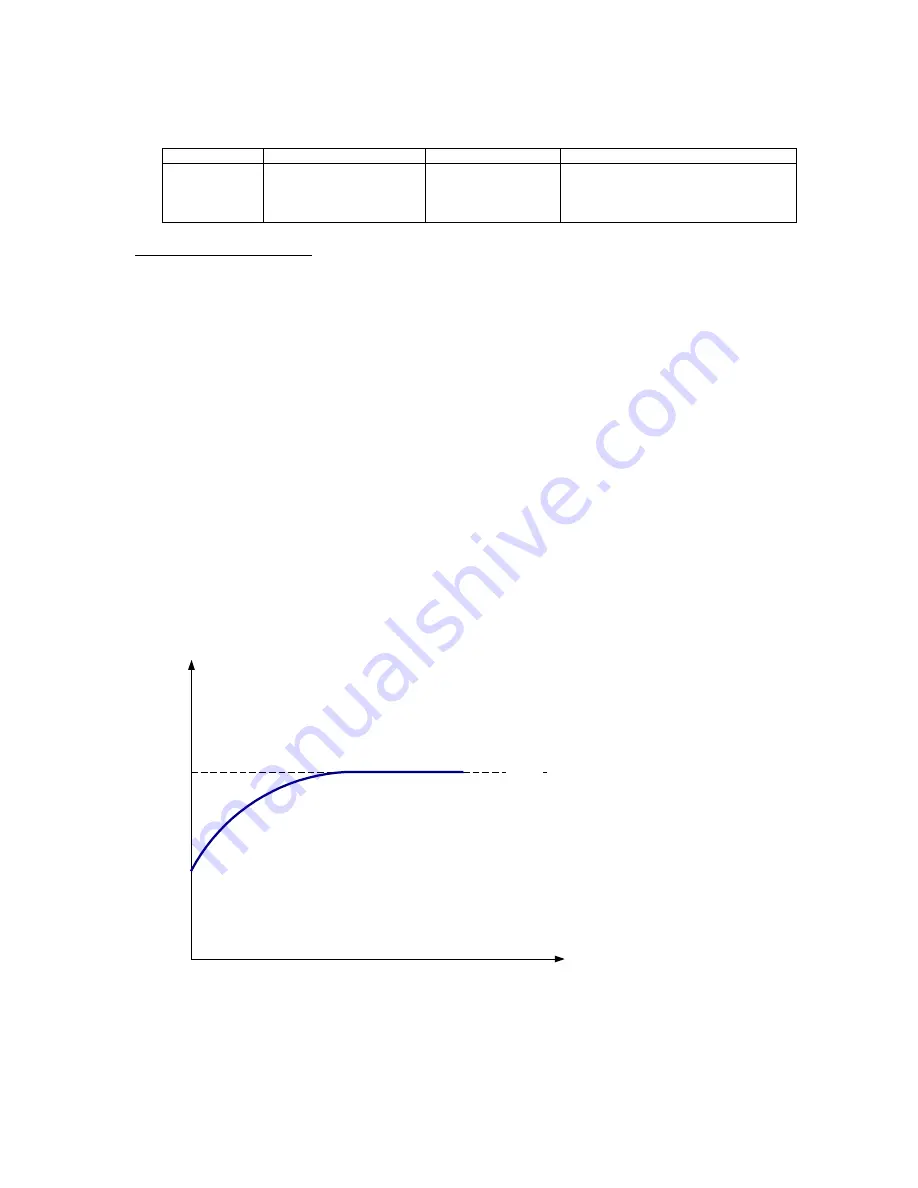

Setpoint

Proc

e

ss Var

iable

Time

Normally tuned system

: This system has appropriate gain and integration times resulting in a smooth transition

towards the setpoint.

Summary of Contents for PumpSmart PS200

Page 1: ... PUMPSMART CONTROL SOLUTIONS PS200 Version 4 0 Configuration Operation Guide ...

Page 2: ......

Page 4: ......

Page 8: ......

Page 26: ......

Page 72: ......

Page 105: ......

Page 119: ......

Page 146: ...PS200 Configuration Operation Guide APPENDIX A 3 PARAMETER LISTING Page 143 ...

Page 147: ......

Page 158: ......