PS200 Configuration & Operation Guide

MULTI PUMP-PROCESS CONFIGURATION

Page 27

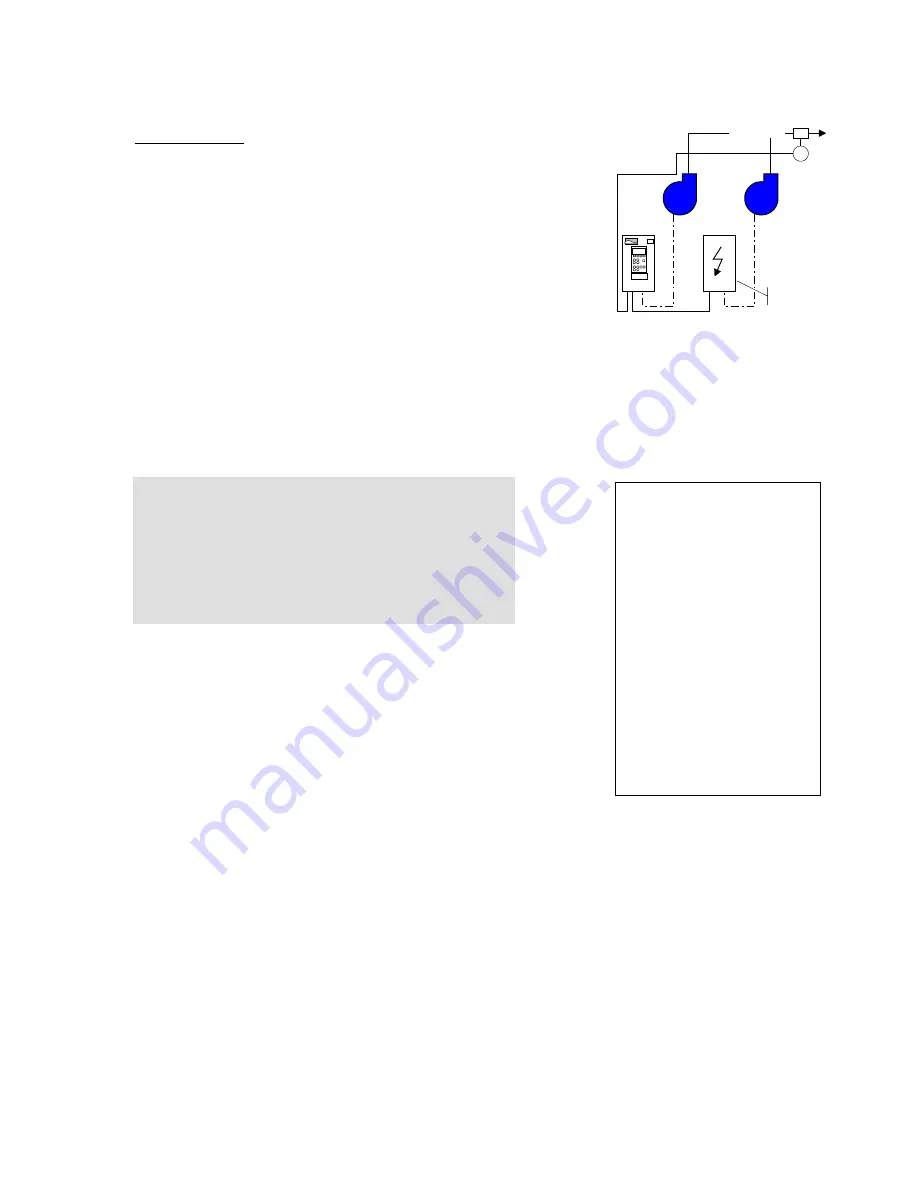

CONSTANT SLAVE

In constant slave mode, one PumpSmart PS200 can be used in

combination with conventional fixed speed pumps to meet

varying demands. The PS200 will signal the constant speed

pumps to turn on during periods of peak demand. The PS200

unit will then regulate speed to “trim” to the setpoint. This

configuration reduces the number of required PumpSmart

PS200 units to one. When demand drops, PumpSmart will

stop the lagging pump.

Up to three constant speed pumps may be used with the

PS200 system.

In constant slave mode, the PS200 is always the lead pump

and the constant speed pump is always the lag pump.

NOTE

It is possible to use dissimilar pumps in any of the above

Multi-Pump modes. Caution should be exercised however to

ensure that pump head curves are similar to prevent

operation at shut-off or check valve chatter on the lower

head pump(s).

IT IS RECOMMENDED THAT ALL PUMPS BE IDENTICAL IN

PERFORMANCE

1

2

Discharge Header

F

Standard starter

What's Lead and What's

Lag?

A LEAD pump is the pump

that runs before all others are

activated. This may

sometimes be referred to as

the

PRIMARY

unit.

A LAG pump starts only when

the demand on the system

becomes greater than what

the lead pump can handle.

This is sometimes called the

BACKUP

or

SECONDARY

unit.

LEAD's and LAG's can be

switched to allow for uniform

wear. See OPTIONS &

FEATURES for details.

Constant Slave Configuration

Summary of Contents for PumpSmart PS200

Page 1: ... PUMPSMART CONTROL SOLUTIONS PS200 Version 4 0 Configuration Operation Guide ...

Page 2: ......

Page 4: ......

Page 8: ......

Page 26: ......

Page 72: ......

Page 105: ......

Page 119: ......

Page 146: ...PS200 Configuration Operation Guide APPENDIX A 3 PARAMETER LISTING Page 143 ...

Page 147: ......

Page 158: ......