PS200 Configuration & Operation Guide

OPTIONS & FEATURES

Page 71

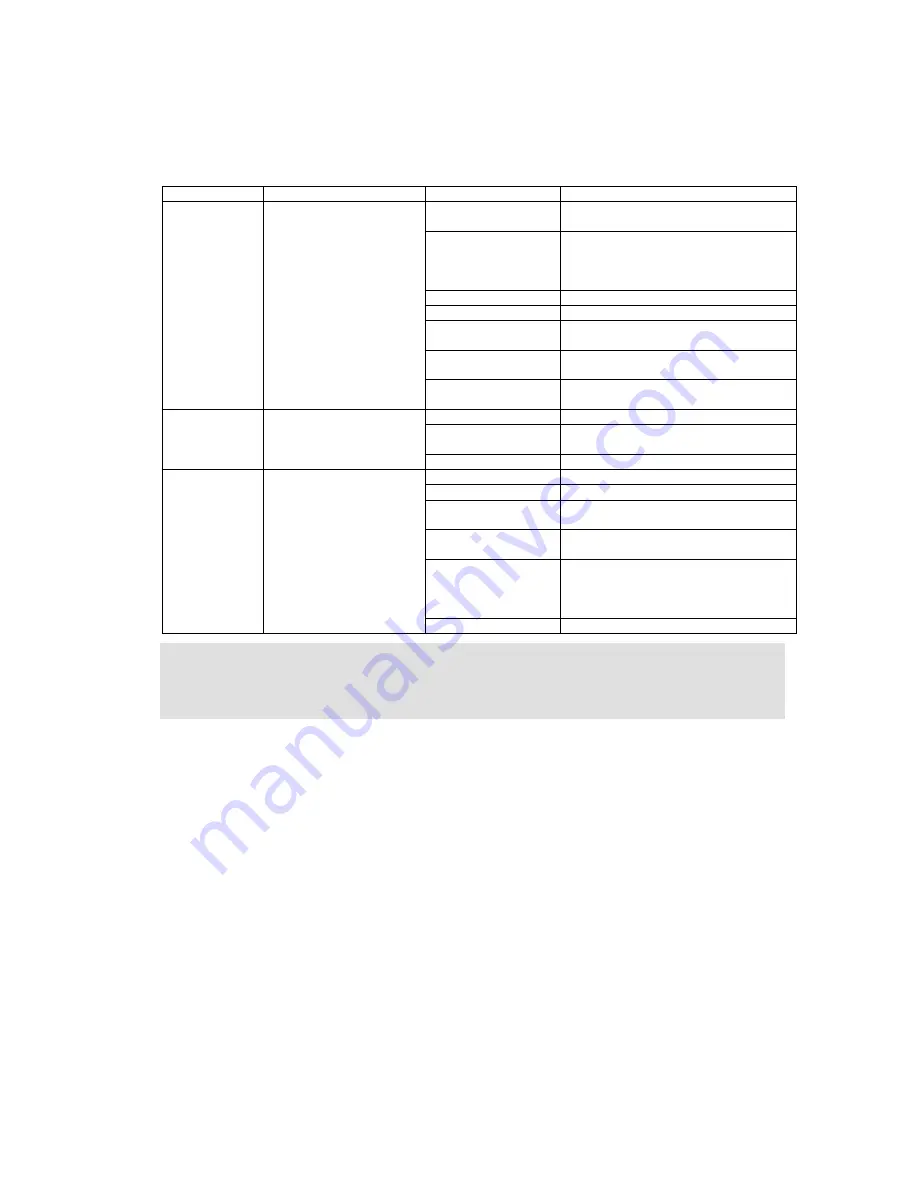

Analog Input Configuration

The PumpSmart PS200 Analog Input default settings may be altered if required.

Parameter

Name

Value/Range

NOTES

PROC TRANS 2

Used for creating offsets with a second

process transmitter

EXT SETPOINT

Used for remotely inputting an

operating setpoint using an analog

signal or a variable setpoint using a

second process transmitter.

VIBRATION 2

Used for vibration signal #2

CONDITION 2

Used for general condition signal #2

SPD CTRL REF

Used for speed control mode when

external speed signal is present.

PWM SIGNAL

Used if a flow or pressure transmitter is

required for the Pump Wear Monitor.

17.20

AI1 CONFIG

NOT USED

[default]

Default setting

PROC TRANS 1

Default setting.

SPD CTRL REF

Used for speed control mode when

external speed signal is present

17.21

AI2 CONFIG

NOT USED

Default for Speed Control mode

VIBRATION 1

Used for Vibration signal #1

CONDITION 1

Used for general condition signal #1

PWM SIGNAL

Used if a flow or pressure transmitter is

required for the Pump Wear Monitor.

PROC TRANS 2

Used for creating offsets with a second

process transmitter

EXT SETPOINT

Used for remotely inputting an

operating setpoint using an analog

signal or a variable setpoint using a

second process transmitter.

17.22

AI3 CONFIG

NOT USED

Default setting

NOTES(s):

Analog input channel AI1 is a 2-10 VDC input - 4-20 mA signals may be used if converted to 2-10 VDC signals

using a 500 Ohm resistor bridging the input. Resistors should be

r

1% 1/4 W.

Analog input channels AI2 & AI3 are 4-20 mA inputs

Summary of Contents for PumpSmart PS200

Page 1: ... PUMPSMART CONTROL SOLUTIONS PS200 Version 4 0 Configuration Operation Guide ...

Page 2: ......

Page 4: ......

Page 8: ......

Page 26: ......

Page 72: ......

Page 105: ......

Page 119: ......

Page 146: ...PS200 Configuration Operation Guide APPENDIX A 3 PARAMETER LISTING Page 143 ...

Page 147: ......

Page 158: ......