PS200 Configuration & Operation Guide

OPTIONS & FEATURES

Page 83

Motor Thermal Protection

The motor can be protected against overheating by the motor thermal protection function. The default method of

protection is a motor temperature thermal model created by the PS200. The PS200 calculates the temperature of

the motor assuming an ambient temperature of 30 C (86 F) when power is applied to the PS200. The thermal

model can be User adjusted if the ambient temperature exceeds 30 C (86 F). Refer to your PumpSmart

Applications group for guidance.

NOTE - Parameters 24.05 and 24.06 are in the Advanced Parameter Group accessible by User Pass Code 564.

Parameter

Name

Value/Range

Notes

24.05

MOTOR THERM PROT

WARNING

[default]

FAULT

NO

This parameter defines the reaction of

PumpSmart when it calculates a

potential motor thermal fault. FAULT

will shut the pump down. NO will result

in no warning or fault shutdown.

24.06

MOTOR THERM PMODE

DTC

[default]

USER MODE

THERMISTOR

This defines how PumpSmart will

determine a motor thermal fault. DTC

uses the ABB DTC control algorithm

while THERMISTOR uses a physical

thermistor placed in the motor.

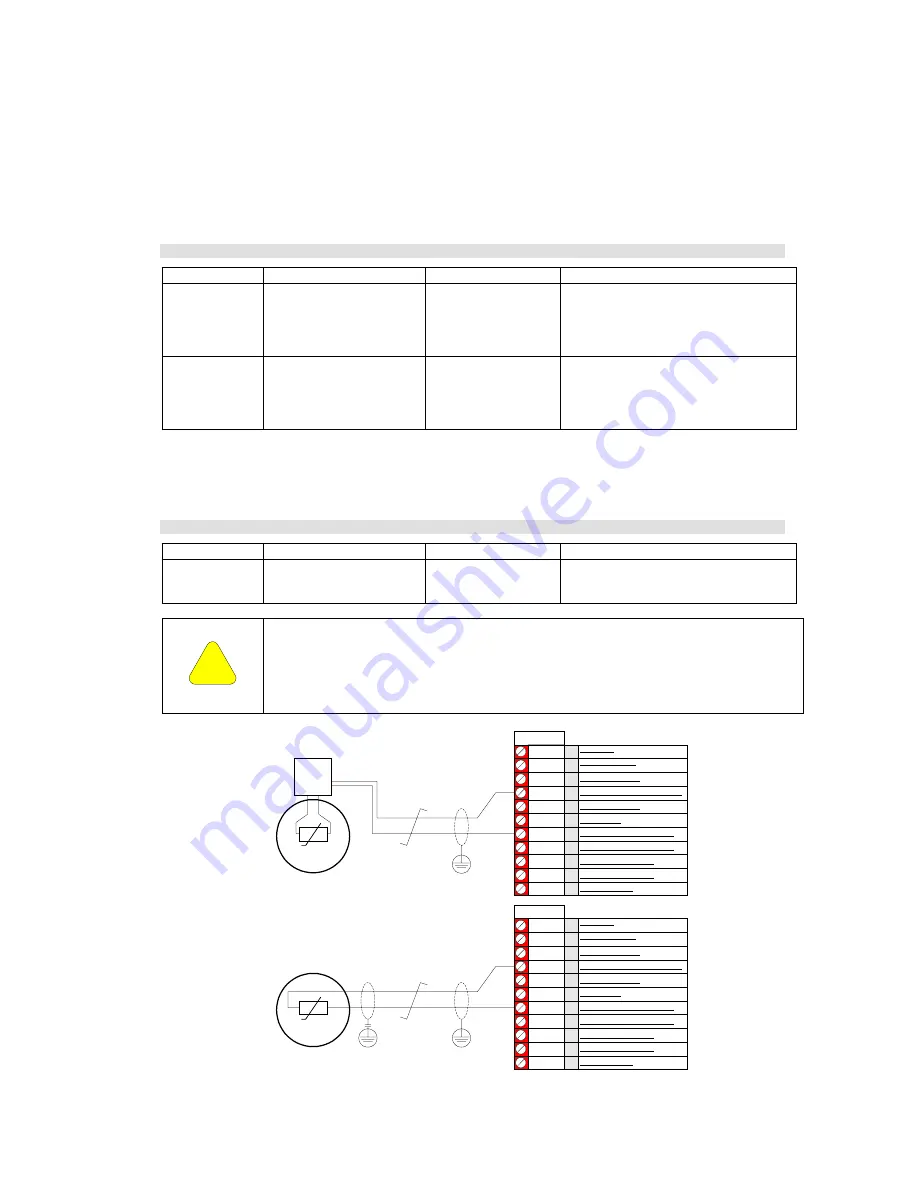

An alternate method of detecting motor overheating is by use of a motor thermistor. The thermistor or a break

contact of a thermistor relay is connected between the PS200 in24 VDC voltage supply and digital input 4

(DI4). Under normal motor temperature operation the thermistor resistance should be less than 1.5kohm (current

5 mA). The PS200 will warn the user or fault (see parameter 24.05) if the thermistor resistance exceeds 4 kOhm. If

using a motor thermistor, parameter 25.06 Secondary Protect A must be set to “Thermistor”.

NOTE - Parameter 24.06 Motor Thermal P Mode will automatically update to the Thermistor setting.

Parameter

Name

Value/Range

Notes

25.06

SECONDARY PRTCT A

DISABLED

[default]

ALARM & CTRL

THERMISTOR

Select THERMISTOR when a motor

thermistor is wired at DI4

!

!! WARNING !!

According to IEC664, the connection of the motor thermistor to a digital input requires double or

reinforced insulation between motor live parts and the thermistor. Reinforced insulation entails a

clearance and creeping distance of 8 mm (0.31 in) for 400/500 VAC input voltages. If the thermistor

assembly does not fulfill the requirement, the other I/O terminals of the drive must be protected

against contact, or a thermistor relay must be used to isolate the thermistor from the digital input.

1 DI1

2 DI2

3 DI3

4 DI4

5 DI5

6 DI6

7 +24 VDC

8 +24 VDC

9 GROUND

10 GROUND

11 DIIL

X22

DIGITAL SWITCH POWER SOURCE

DIGITAL SWITCH POWER SOURCE

DIGITAL SWITCH GROUND

SETPOINT SELECTION

SECONDARY PRTCT B

DIGITAL RESET

SECONDARY PRTCT A / THERMISTOR

DIGITAL SWITCH GROUND

DRIVE PERMISSIVE

OPT

OPT

START/STOP

2 WIRE/HOA Configuration

MANUAL OVERRIDE

2 WIRE/HOA Configuration

OPT

OPT

OPT

OPT

OPT

OPT

OPT

OPT

OPT

Motor

T

10 nF

1 DI1

2 DI2

3 DI3

4 DI4

5 DI5

6 DI6

7 +24 VDC

8 +24 VDC

9 GROUND

10 GROUND

11 DIIL

X22

DIGITAL SWITCH POWER SOURCE

DIGITAL SWITCH POWER SOURCE

DIGITAL SWITCH GROUND

SETPOINT SELECTION

SECONDARY PRTCT B

DIGITAL RESET

SECONDARY PRTCT A / THERMISTOR

DIGITAL SWITCH GROUND

DRIVE PERMISSIVE

OP

T

OP

T

START/STOP

2 WIRE/HOA Configuration

MANUAL OVERRIDE

2 WIRE/HOA Configuration

OP

T

OP

T

OP

T

OP

T

OPT

OP

T

OPT

OP

T

OPT

Motor

T

Thermistor

Relay

OP

TI

O

N

1

OPTIO

N

2

Summary of Contents for PumpSmart PS200

Page 1: ... PUMPSMART CONTROL SOLUTIONS PS200 Version 4 0 Configuration Operation Guide ...

Page 2: ......

Page 4: ......

Page 8: ......

Page 26: ......

Page 72: ......

Page 105: ......

Page 119: ......

Page 146: ...PS200 Configuration Operation Guide APPENDIX A 3 PARAMETER LISTING Page 143 ...

Page 147: ......

Page 158: ......