Series FS8-W

General Purpose

Liquid Flow Switch

OPERATION

This control is an independently mounted water flow

sensing device that makes or breaks an electrical

circuit when flow stops or starts.

• Before using product, read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of plumbing, steam and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• To prevent electrical shock, turn off the electrical power before making electrical

connections.

• To prevent an electrical fire or equipment damage, electrical wiring insulation must have a

rating of 167˚F (75˚C) if the liquid’s temperature exceeds 180˚F (82˚C).

• To prevent electrocution, when the electrical power is connected to the flow switch, do not

touch the terminals.

• Make sure flow switch electrical cover is secured before turning on electric power.

Failure to follow this warning could cause property damage, personal injury or death.

WARNING

CAUTION

!

WARNING

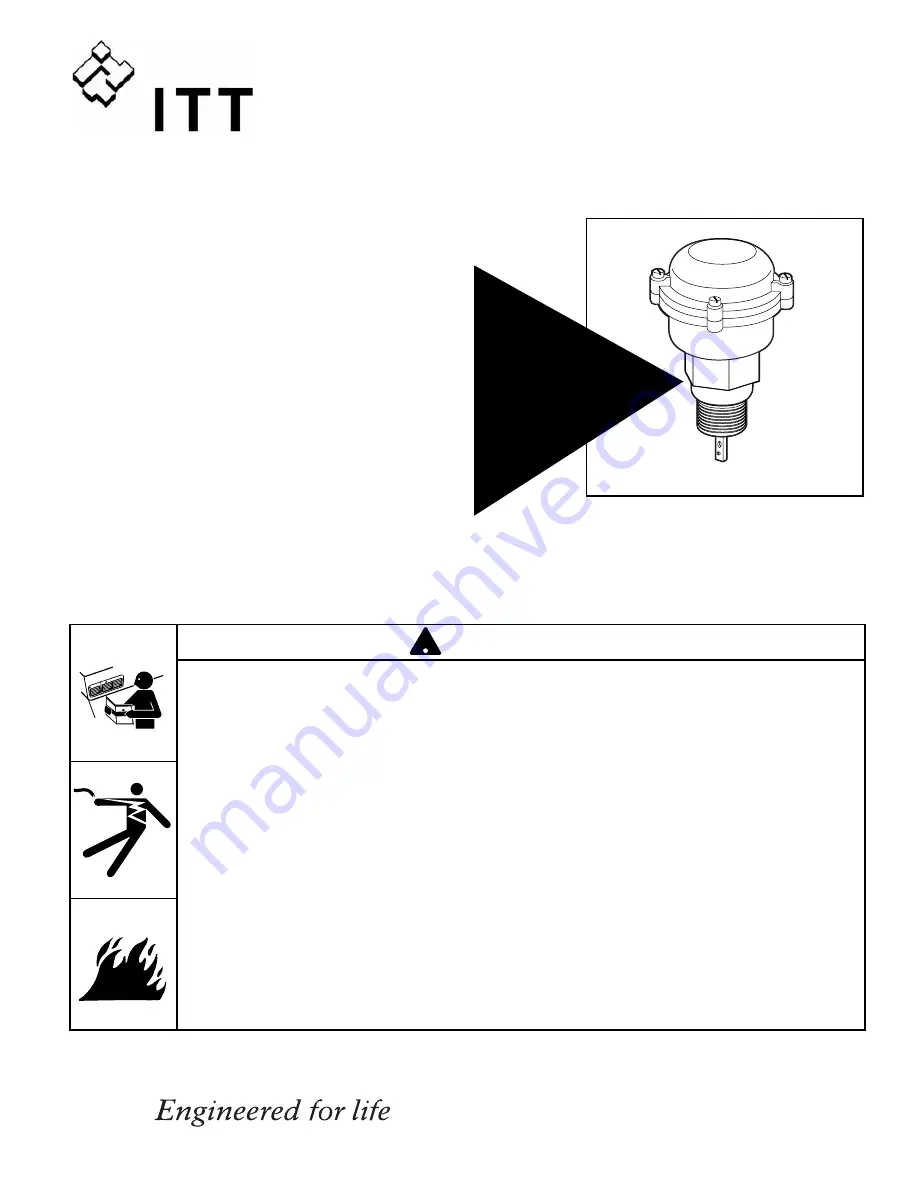

Series FS8-W

Now

with

Stainless Steel

Paddles

McDonnell & Miller

Installation & Maintenance

Instructions

MM-600(G)