NG DP

TECHNICAL SERVICE MANUAL

26

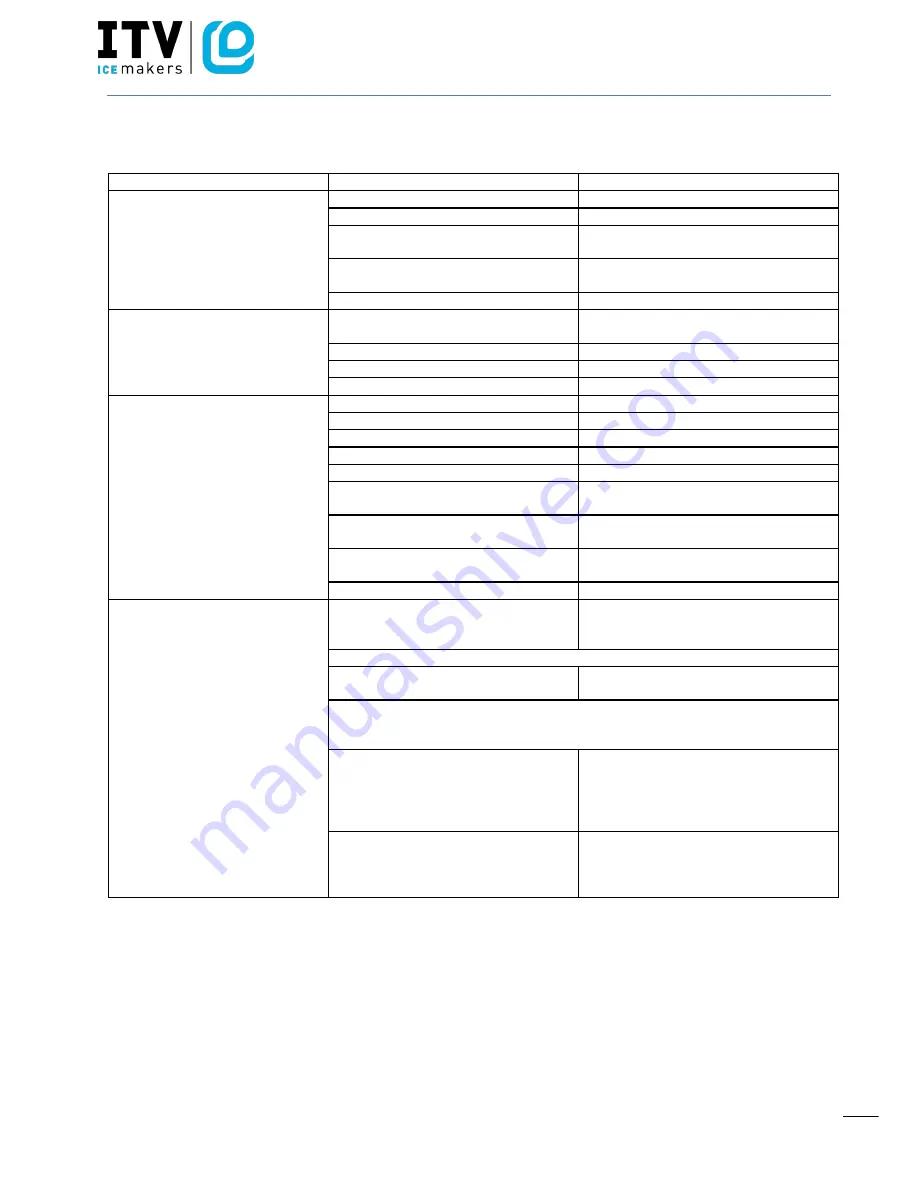

10. TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSES

SOLUTION

1) None of the electrics work.

A) The machine is not plugged in.

A) Plug the machine.

B) The line fuse has blown.

B) Replace fuse.

C) The current line is wrongly

connected in the junction box.

C) Check connections.

D) The cut off micro-switch is faulty or

wrongly adjusted.

D) Check, adjust or change.

E) Safety pressure switch faulty.

E) Replace.

2) All the electrics work except

compressor.

A) Check switch installed in electrical

panel.

A) Select position 1..

B) Faulty relay .

B) Replace relay.

C) Faulty

“Klixon”.

C) Replace Klixon.

D) Faulty compressor.

D) Replace compressor.

3) All the electrics work but the

compressor

“klixons”

A) Voltage too low.

A) Check voltage.

B) Dirty condenser.

B) Clean condenser.

C) Obstruction in air circulation.

C) Move machine to a correct position.

D) Fan has broken.

D) Replace fan.

E) Starter capacitor faulty.

E) Replace condenser.

F) Fan pressure swtich faulty or

wrongly adjusted.

F) Replace or adjust pressure switch

G) Water pressure switch valve

faulty or wrongly adjusted.

G) Replace or adjust.

H) Cooling water pressure switch is

faulty or badly adjusted.

H) Adjust or change.

J) Non-condensable gases in system. J) Purge system.

4) Everything appears to be

running correctly but no ice is

being

made

in

the

evaporator.

A) Unprimed pump.

A) Check overflow, water bin for leaks,

water entry valve and prime the

pump.

B) Faulty pump.

B) Replace.

C) Water does not enter into the bin.

C) Check water entry valve and change

if is necessary.

D) There is water in the gas circuit.

D) Replace the drier, empty the

refrigerant (vacuum) and charge

new refrigerant.

E) Water tray is dry.

E) Check overflow pipe and for leaks.

Inspect draining valve in machines

with automatic cleaning system.

Check the buoy valve mechanism

in DP90 and DP140.

F) Freezing system is faulty (dirty

condenser, water pressure switch

or entrance

valve

faulty

or

wrongly

adjusted

insufficient

refrigerant.

F) Clean condenser, check all the

system

components:

pressure

switch, water inlet valve, refrigerant

charge, etc.