SERVICE MANUAL SPIKA SERIES

12

Damages due to the lack of maintenance and cleaning operations are not included on the

warranty.

3.2. Start-Up

Once the installation instructions are followed (ventilation, site conditions, temperatures, water

quality, etc.), proceed as follows:

1.- Open the water inlet. Verify the no existence of leakages.

2.- For under counter models open the door and remove the protection elements on the shield.

For modular models remove the two locking screws on top of machine, take off the front panel

and remove protection elements on the shield and also on the thickness sensor.

3.- Verify that the shield moves freely. For modular models verify also the thickness sensor

moves freely.

4.- Connect the machine to the power supply.

5.- For under counter models: push the blue switch on the machine front side. For modular

models: push the blue switch found on the back of the machine and then set the ice-wash

switch to the position I.

6.- Verify that there are no vibrations or frictions on the elements.

7.- Verify that the water fall to the evaporator is occurring uniformly and all ice cubes are

properly watered.

8.- Close door (for under counter models) / Replace the front panel in its place (for modular

models).

9.- Verify that after the final cycle, the frost on the aspiration pipe is at 0.78 in (20 mm) of the

compressor.

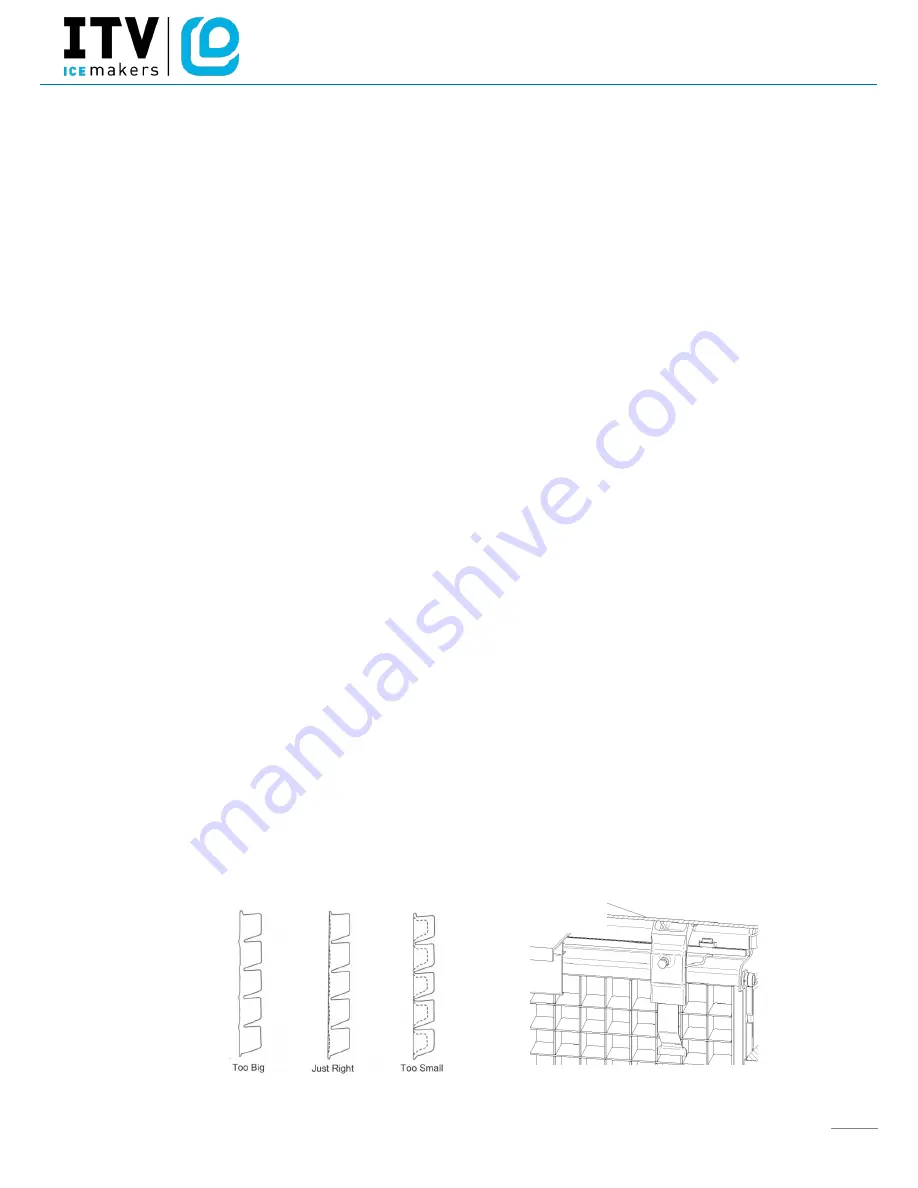

10.- For modular models: Verify the ice slab with the pictures below. In case the thickness

sensor needs to be regulated, rotate the thickness adjustment screw CW to increase bridge

thickness. Rotate CCW to decrease bridge thickness. For under counter models adjust the cycle

thermostat.

Thickness

sensor

Summary of Contents for SPIKA MS 1000

Page 39: ...SERVICE MANUAL SPIKA SERIES 39 9 WIRING DIAGRAMS 9 1 SPIKA NG under counter models ...

Page 40: ...SERVICE MANUAL SPIKA SERIES 40 9 2 SPIKA MS 700 ...

Page 41: ...SERVICE MANUAL SPIKA SERIES 41 9 3 SPIKA MS 500 AND SPIKA MS 1000 A W ONE PHASE ...

Page 42: ...SERVICE MANUAL SPIKA SERIES 42 9 4 SPIKA MS 1000 THREE PHASES ...