Chapter 10

Appendix

ITW Dynatec

UFD Applicator, Manual 40-43, Rev. 6.16

Page 105

Chapter 10

Appendix

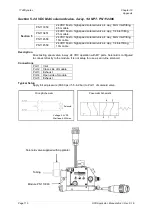

Solenoid Valve Configurations, Schematics & Setup

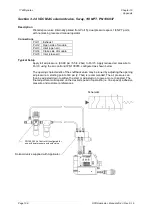

This Appendix covers the pneumatic setup of the solenoid valves used to actuate the adhesive

modules. A coalescing filter/ regulator kit (PN 100055) is available to provide regulated, oil-free air to

the solenoid valves. The kit also contains the necessary fittings and tubing to configure the kit for each

particular solenoid valve.

Some typical solenoid valve setups are shown on the following pages. While the most commonly used

solenoid valves are shown, other valves not listed here may be used if required for the particular

application. In general, however, the setups shown here can be applied to any solenoid valve. If there

are questions about a valve that was supplied with the Applicator, and it is not shown here, consult

ITW Dynatec.

The Appendix is divided into sections for easy reference:

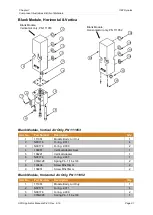

Section 1

PN 100054

24 VDC MAC solenoid valve, 4 way, 02, 1/8 NPT

Section 2

PN 100383

24 VDC MAC solenoid valve, 4 way, 1/4 NPT

PN 100421

120 VAC MAC solenoid valve, 4 way, 1/4 NPT

PN 811506

240 VAC MAC solenoid valve, 4 way, 1/4 NPT

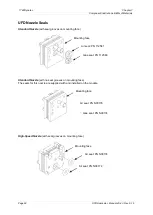

Section 3

PN 106937

24 VDC MAC solenoid valve, 5 way, 1/8 NPT

Section 4

PN 112496

24 VDC MAC solenoid valve, 4 way, 1/4 NPT

Section 5

PN 113350

24 VDC Festo high speed solenoid valve, 4 way, 6mm inlet fitting,

2.5m cable

PN 113451

24 VDC Festo high speed solenoid valve, 4 way, 1/4 inlet fitting,

2.5m cable

PN 114558

24 VDC Festo high speed solenoid valve, 4 way, 6mm inlet fitting,

10m cable

PN 114559

24 VDC Festo high speed solenoid valve, 4 way, 1/4 inlet fitting,

10m cable

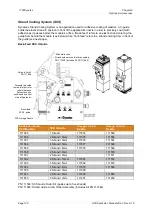

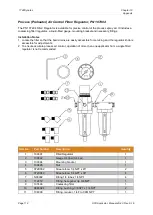

Section 6

PN 100055

Component Illustration: 100055 Air Control Kit

Air Filter/ Regulator Installation Notes

1. Compressed air for Applicator operation should be clean, dry and oil free.

2. In general, operation of more than one Applicator from a single air control kit is not recommended,

because Applicator response time may be increased and synchronization may be more difficult.

3. Install the filter/ regulator so that the bowl drains are easily accessible for servicing and the

regulator knob is accessible for adjustments.

4. Use a minimum of 1/4” OD tubing to make connections.

5. If air tubing is routed close to the Applicator due to space constraints, high temperature TFE tubing

should be used to avoid tubing damage.