Chapter 5

Maintenance and Repair Notes

ITW Dynatec

UFD Applicator, Manual 40-43, Rev. 6.16

Page 33

5.4 Relieving Adhesive Pressure

WARNING

Heed all security advices given in Chapter 5.1.

Maintenance and repair work is only permitted for skilled personnel!

Always wear safety shoes, heat-resistant protective gloves, safety goggles

and protective clothing that cover all vulnerable parts of the body while

working on the heated unit! Risk of injury or severe burns!

Components and adhesive are hot. Take every precaution to prevent the

material and hot surfaces from contacting the skin.

During the purging procedure, hot adhesive can come out of the

Applicator under high pressure. Wear safety glasses, gloves and

protective clothing.

Many maintenance and troubleshooting procedures potentially expose the maintenance

technician to dangerous hot adhesive, which is under pressure. Follow this procedure to

release the adhesive pressure in the Applicator before performing such maintenance.

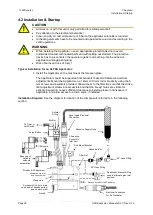

1. The Applicator should be at operating temperature.

2. Turn the ASU’s pump/ motor OFF.

3. Place a heat-resistant catchment container/underlay under the Applicator.

Relieving Adhesive Pressure Manually:

1. Push the purge button located on the side of the air solenoid coil.

Or, if the ASU filter block is equipped with a drain, adhesive pressure may be relieved

at the ASU.

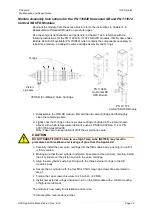

Relieving Adhesive Pressure by using the Optional Drain Valve (if applicable):

1. Place a heat-resistant container under the drain valve. If necessary, rotate the drain

valve’s opening by turning its knurled collar so that the opening is aiming downward

into the container.

2. With a 5mm hex key screwdriver (Allen-wrench), slowly loosen the drain valve’s purge

screw (do not try to remove it) and allow the adhesive and residues to flow out of

Applicator. Be sure to stand clear since there may be residual adhesive pressure in

the Applicator.

3. Turn ON the ASU’s pump/ motor. When all the contaminants have run out and the

adhesive is clean, retighten the screw.