ITW Dynatec

Chapter 6

Troubleshooting

Page 52

UFD Applicator, Manual 40-43, Rev. 6.16

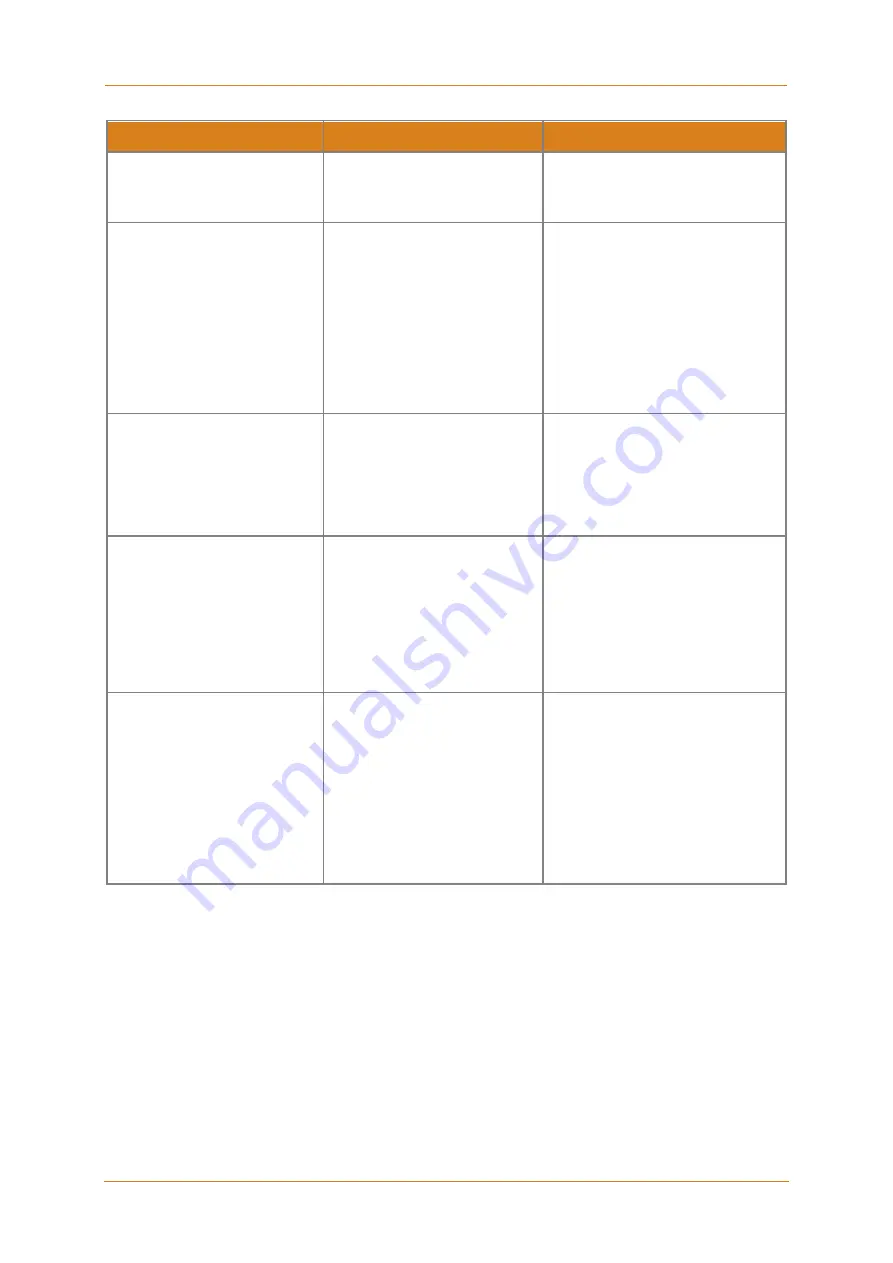

Problem

Possible Cause

Solution

Hot melt is coming out of the

module’s “weep” holes.

1. Module seals are

damaged.

1. Replace seal cartridge or

module, see instructions in

Ch. Maintenance.

Applicator does not reach

operating temperature

1. Hopper temperature

setpoint is too low.

2. Heater cartridge defective.

3. Temperature sensor

defective.

1. Change setpoint, see ASU

manual.

2. Check/ replace heater

cartridge, see instructions in

Ch. Maintenance.

3. Check/ replace sensor, see

instructions in Ch.

Maintenance.

Applicator is too hot

1. Applicator temperature

setpoint is too high.

2. Temperature sensor

defective.

1. Change setpoint, see ASU

manual.

2. Check/ replace sensor, see

instructions in Ch.

Maintenance.

Air escapes from module

1. Piston O-ring defective.

2. O-rings located between

module and service block

are defective.

1. Replace O-ring, see

instructions in Ch.

Maintenance.

2. Remove module from block

(see instructions in Ch.

Maintenance) and replace O-

rings.

Application pattern is erratic

1. Adhesive pressure is too

low.

2. Adjust pattern controller.

1. a.

For units without speed

control:

increase adhesive

pressure at ASU.

b.

For units with speed control

(tach follower):

adjust pump

speed control.

2. See pattern controller manual

for proper adjustment.