ITW Dynatec

Chapter 7

Component Illustrations & Bills of Materials

Page 88

UFD Applicator, Manual 40-43, Rev. 6.16

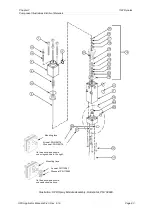

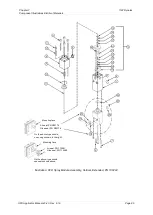

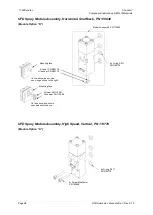

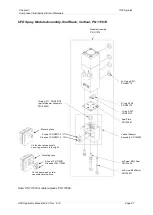

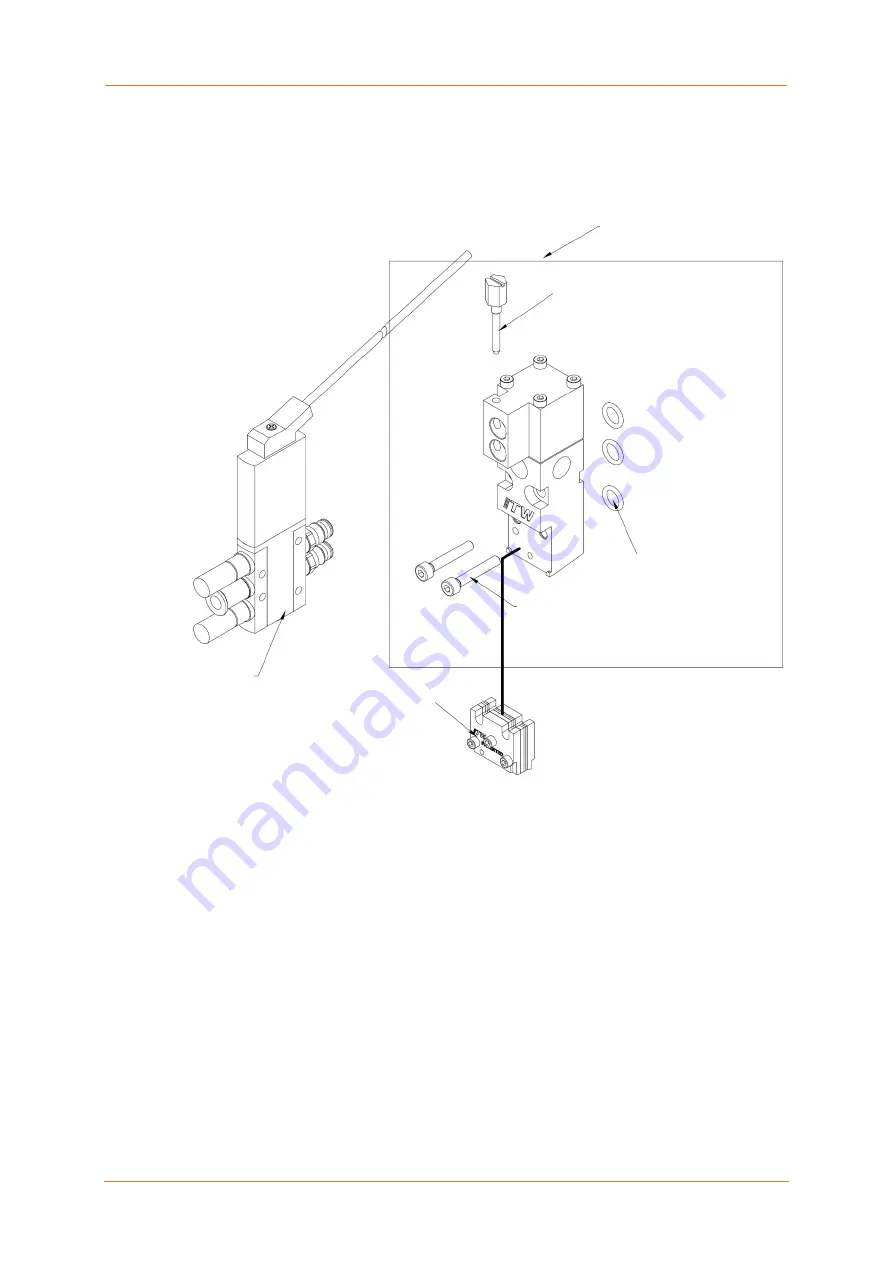

UPD Spray Module Assembly, High Speed, Vertical, PN 113346

(Module Option “J”)

Module Assembly

PN 113346

Solenoid Retaining Ring

PN 113348

3x O-ring 2-011

PN N00178

2x Screw M4x25mm

PN 100908

High Speed Nozzle Assembly

(for reference only)

High Speed Solenoid Assembly

(for reference only)