V

10/04

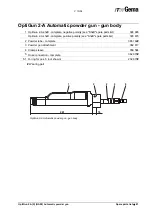

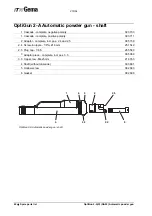

OptiGun 2-A(X) (GA02) Automatic powder gun

Spare parts list

•

49

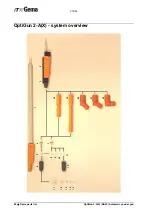

OptiGun 2-A(X) - system overview

1 OptiGun 2-AX Automatic powder gun

2 OptiGun 2-A Automatic powder gun - complete, with flat jet nozzle set, gun cable

(20 m), parts set, cleaning brush, without SuperCorona, negative polarity

393 568

OptiGun 2-A Automatic powder gun - complete, with flat jet nozzle set, gun cable

(20 m), parts set, cleaning brush, without SuperCorona, positive polarity

393 576

3 SuperCorona - complete

385 174

Nozzle set - round jet nozzle (pos. 4 and 5)

382 922

4 Electrode holder (round jet nozzle central electrode)

382 914

#

5 Round jet nozzle

378 518

#

6 Sleeve nut

379 166

Nozzle set - flat jet nozzle (pos. 7 and 8)

1000 047

#

7 Electrode holder (flat jet nozzle)

1000 055

#

8 Flat jet nozzle - NF08

1000 049

#

9 Flat jet nozzle - NF04 (slot in round form)

383 082

#

10 Flat jet nozzle - NF02 (without slot)

384 887

#

11 Flat jet nozzle - NF03 (nozzle front part Ø 24 mm)

383 058

#

12 Sleeve nut for pos. 11

383 074

13 Deflector plate - Ø 16 mm (0,63 in)

331 341

#

14 Deflector plate - Ø 24 mm (0,94 in)

331 333

#

15 Deflector plate - Ø 32 mm (1,26 in)

331 325

#

16 Deflector plate - Ø 50 mm (1,97 in)

345 822

#

17 Deflector plate - Ø 70 mm (2,76 in)

353 949

#

18 Extension - 150 mm (5,91 in)

378 852

#

19 Extension - 300 mm (11,82 in)

378 860

#

20 Angle nozzle - PA01-45° - complete (incl. round jet nozzle with deflector Ø 24 mm)

390 232

21 Angle nozzle - PA01-60° - complete (incl. round jet nozzle with deflector Ø 24 mm)

383 724

22 Angle nozzle - PA01-90° - complete (incl. round jet nozzle with deflector Ø 24 mm)

383 520

#

Wearing part