V

05/10

OptiFlex B manual coating equipment

Start-up and operation

19

Start-up and operation

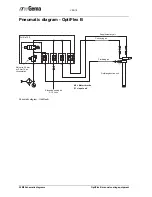

Connecting guide

1. Check the compressed air connection from the filter unit to

the control unit. Connect the compressed air supply hose

from the compressed air circuit directly to the filter unit main

connection on the rear side of the equipment (1/4" female

BSP).

Note:

The compressed air must be free from oil and water!

2. Connect the black hose for fluidizing air to the output

1.5

on

the rear side of the control unit

3. Connect the grounding cable to the control unit with the

grounding screw, and the 5 m long grounding cable with the

clamping clip to the booth or the conveyor. Check ground

connections with Ohm meter and ensure 1 MOhm or less

4. Connect the gun cable plug to the socket

2.3

on the rear side

of the control unit

5. Connect the rinsing air hose to the electrode rinsing air out-

put

1.4

and to the powder gun

6. Attach the injector, connect the powder hose to the injector

and to the powder gun

7. Connect the red hose for conveying air to the corresponding

output

1.2

on the rear side of the control unit and to the injec-

tor

8. Connect the black hose for supplementary air to the corres-

ponding output

1.3

on the rear side of the control unit and to

the injector (this hose is electrically conducting)

9. Connect the mains cable to the

2.1 Power IN

plug and tigh-

ten with provided screw

Note:

If no vibration motor is connected, the 2.2 Aux output is to be

locked tightly with the provided protection cap!