OM-2245 / Operation and Maintenance Manual

ITW GSE 4400 / 400 Hz. Generator Set

March 15, 2015

Chapter 2-4

Page 3

(1) Warning

Warning faults have no effect on the operation of the GPU. An example is an intake air restriction

fault due to a dirty filter. Although the GPU continues to operate, the fault LED is lit and the fault

text appears on the display. Pressing the

Engine

pushbutton or shutting down the GPU resets

the fault.

(2) Run Mode

Run mode faults remove power form the aircraft but do not change the operating speed of the

engine. An example is an over voltage fault. Although the contactors open and remove power

from the aircraft, the engine remains at rated speed, the fault LED is lit and the fault text appears

on the display. Pressing the

Engine

pushbutton or shutting down the GPU resets the fault.

(3) Stop Mode

Stop mode faults remove power form the aircraft and shut the engine down. An example is a low

oil pressure fault. The contactors open and remove power from the aircraft, the engine shuts

down, the Alert/Failure LED is lit and the fault text appears display. Pressing the

Engine

pushbutton or shutting down the GPU resets the fault.

8) Cummins Engine Fault Codes & Trouble Shooting

The best source of information to aid in trouble shooting Cummins engine issues is at the

quickserve.cummins.com

website. Go to this website and register up to five engine serial numbers for

free. (It is recommended that if you have more than one engine type/size, that you register one serial

number per type/size.) Once you are registered, this website gives you access to engine information,

troubleshooting assistance by fault code, parts information and service bulletin information for each serial

number/engine type that you have registered with the site.

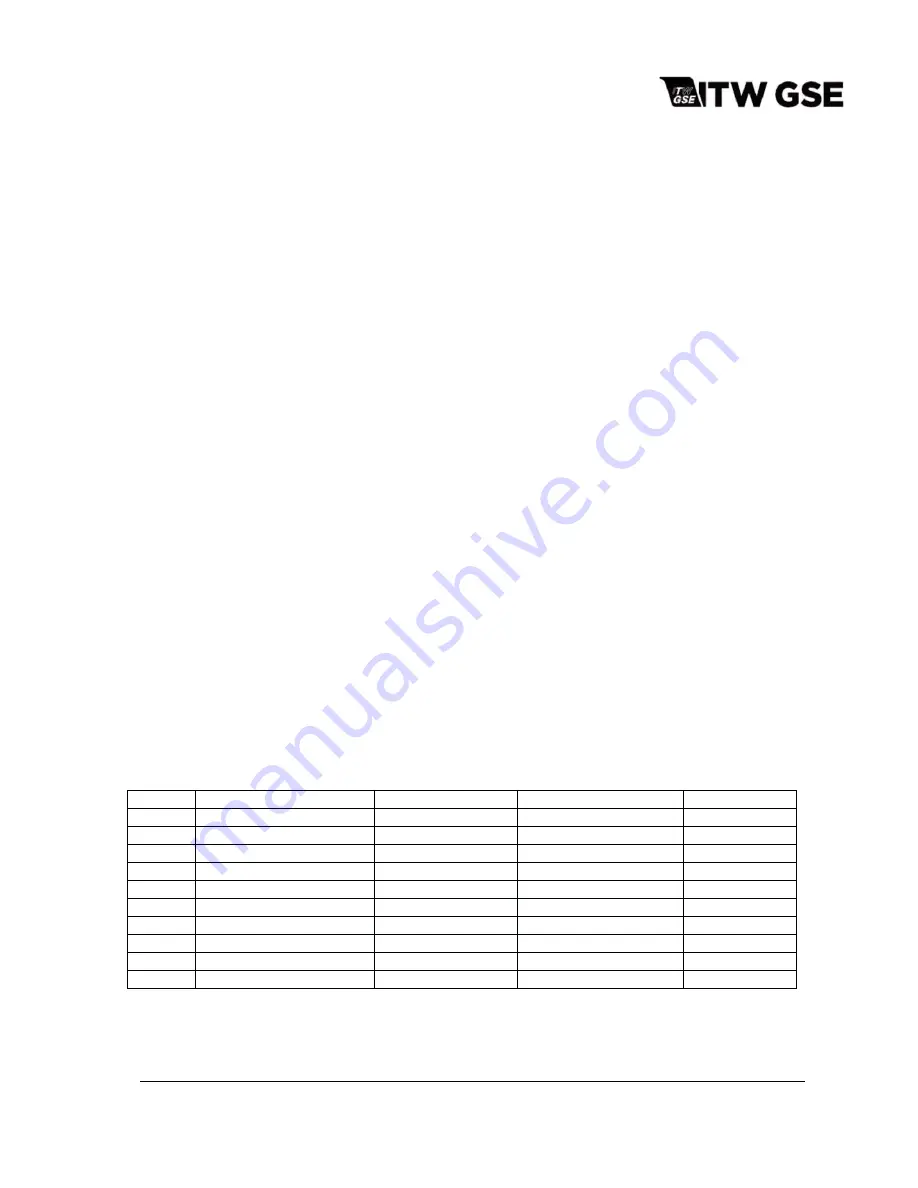

9) Fuses

The following is a list of all of the fuses in the 4400 unit.

F1 to F9 are located on the interface board PC1.

Fuse #

Protects

rating

type

PN

F1

Display

2 amp

ATO

AP-SI2076

F2

Control Board

5 amp

ATO

AP-SI2075

F3

Exciter 24V

5 amp

ATO

AP-SI2075

F4

Contactor

5 amp

ATO

AP-SI2075

F5

Relays

2 amp

ATO

AP-SI2076

F6

Key switch (Ignition)

5 amp

ATO

AP-SI2075

F7

ECM (Dongle)

5 amp

ATO

AP-SI2075

F8

ECM Power

20 amp

ATO

AP-SI2083

F9

Exciter 180V (Out)

6.3amp

600V Cylindrical fuse

AP-SI2082

F10

Intake Air Heater Fuse

150 amp

ANL-150

FU11370

Fuse F10 is located on the Engine Air Cleaner Bracket