ORBIMAT CA

| Operating instructions

Product design

(09.03.15) OW_ORBIMAT_CA_BA_871060202_04_EN

orbitalum tools

GmbH, D-78224 Singen, www.orbitalum.com, Tel. +49 (0) 77 31 792-0

13

3.3

Accessories

Not included as standard.

WARNING

Danger presented by using poor-quality accessories and tools not approved by Orbitalum Tools!

Various injuries and damage to property.

X

Use only original tools, spare parts, materials, and accessories from Orbitalum Tools.

Article

Description

Version

Code

Figure

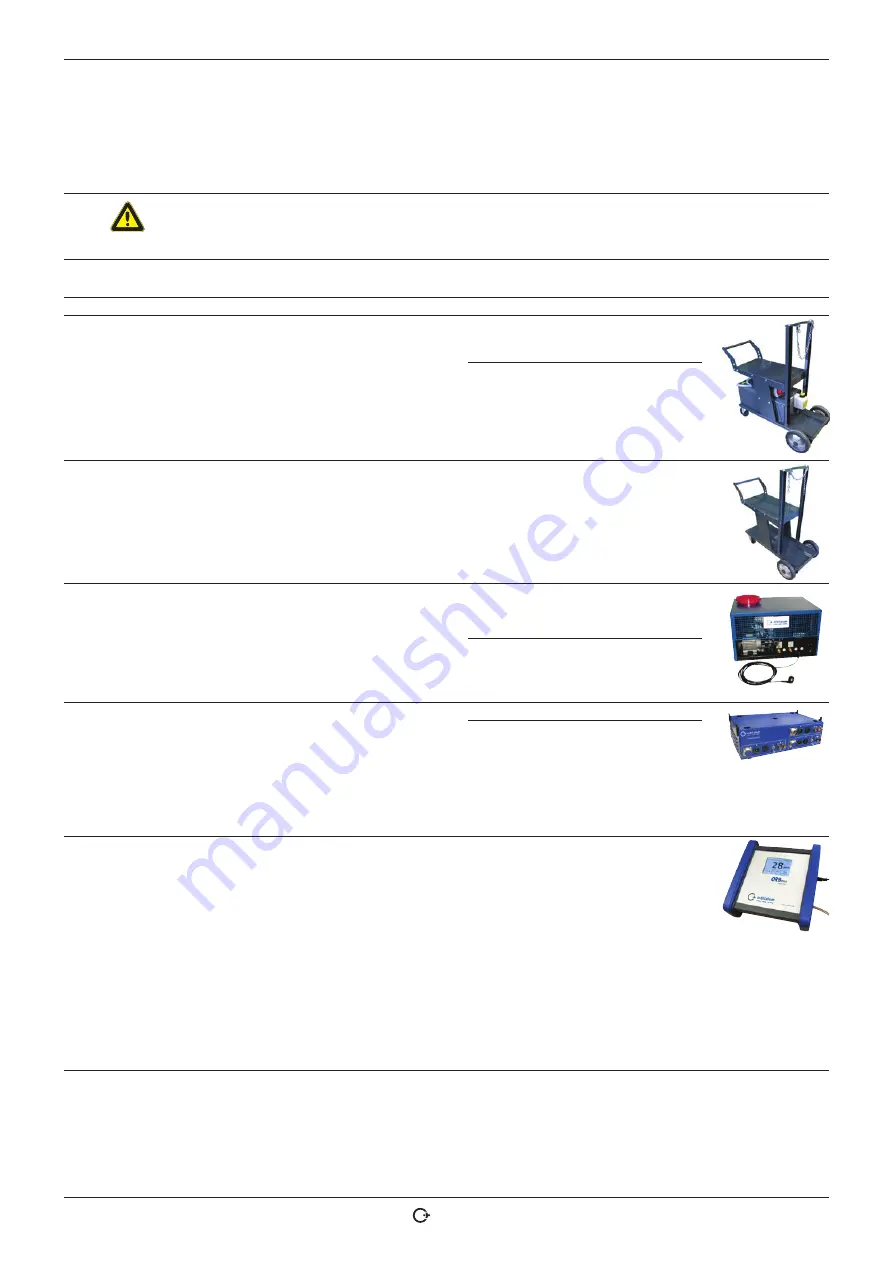

ORBICAR W trolley with

integrated water coolant

The perfect accessory for the Orbitalum 300 A

power supplies.

In addition to the water cooling the trolley has

a gas bottle holder.

For ORBIMAT 300 CB, 300 CA,

300 CA AC/DC, 300 CA AVC/

OSC

884 000 002

For ORBIMAT 165 CA*, 165 CB

* The ORBIMAT 165 CA has to be

modified in our plant.

884 000 004

ORBICAR S trolley

A practical trolley with storage shelf and an

option of securing a gas cylinder.

The ORBICAR S trolley can be combined with

all power supplies of the ORBIMAT series.

This trolley is most commonly used an orbital

welding power supply of the ORBIMAT 165 A

series.

884 000 001

ORBICOOL Active

Very efficient compressor cooling device with

constant and adjustable water temperature.

Including water flow sensor. Significantly

increases cooling performance for the weld

heads. Particularly suitable for welding units in

series production.

Suitable for all* ORBIMAT orbital welding

power supplies.

For ORBIMAT 165 CA*/CB

* The ORBIMAT 165 CA has to be

modified in our plant.

889 000 001

For ORBIMAT 300 CA/CB

889 000 002

ORBITWIN switching

device

To increase productivity, the switching unit

ORBITWIN is available, with which 2 welding

heads can be operated alternately on the OR-

BIMAT. The previously assigned program is

recalled automatically when the start key of

the weld head is actuated. The welding

head that is not being used is locked and can

be prepared for the next welding operation.

Including connection cables and hoses.

For ORBIMAT 165 CA

861 000 001

For all ORBIMAT 300*

* not suitable for AVC/OSC machines.

876 000 001

Oxygen meter ORBmax

NEW optical oxygen measurement method by

fluorescence quenching.

The ideal complement for orbital welding!

• No warm-up time required

• Quick response

• High measurement accuracy

• Measurement of residual oxygen level during

the welding process

• No uncontrolled increase of the measure-

ment during the welding process

• Measurement of forming gas with variable

hydrogen content without mode change

• Measurement of the residual oxygen value in

all gas mixtures

• Measured value recording on SD card

• User-friedly touchscreen

100 - 240 V, 50/60 Hz

882 000 002