ORBIMAT CA

| Operating instructions

Operation

(09.03.15) OW_ORBIMAT_CA_BA_871060202_04_EN

orbitalum tools

GmbH, D-78224 Singen, www.orbitalum.com, Tel. +49 (0) 77 31 792-0

35

• Gas flow: The welding process is interrupted if 3 L/min is undershot.

• The weld current, weld voltage and weld speed process parameters: Limit values specified in the program are taken

into account.

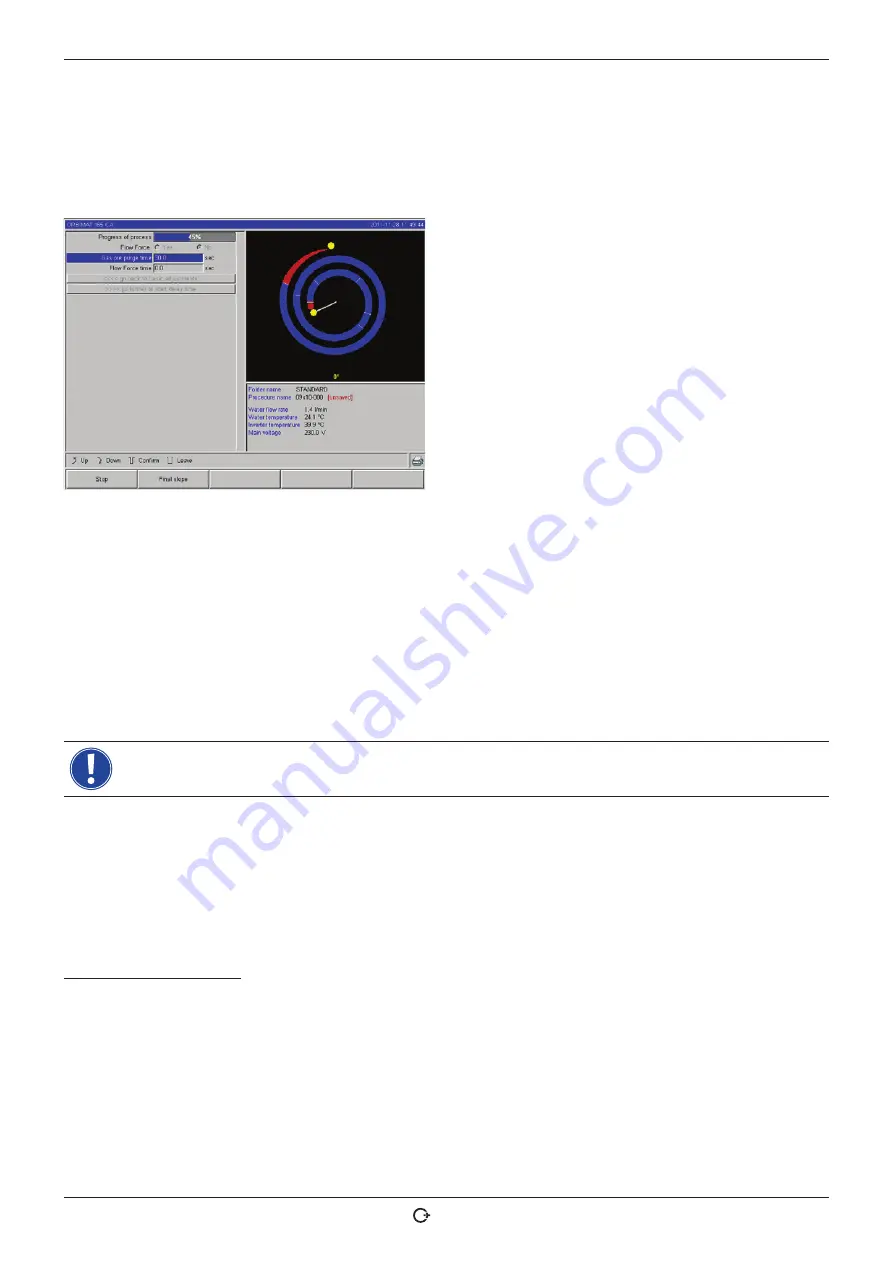

The following details appear in the display during the running welding process:

Progress of process:

Bar graph with specifications of pro-

cess progress (in %) for the respective current sector.

Correction factor:

Percent value by which the current in

the current process was changed in comparison to the

saved procedure.

Parameters Diameter to Wire LP Speed:

Display of the

process parameter of the procedure. The values can be

changed during the welding process. The changes are

saved to the current welding process by pressing the

rotary knob (keyboard: ENTER). The changes are not yet

saved in the procedure. Fields with a gray background

cannot be edited.

Fig. 15:

Display during running welding process

Graphic:

Display of the weld sequence. After starting up, a pointer pointing to the inner yellow dot appears during gas

pre purge. After the gas pre purge, pool formation occurs (the time after ignition during which no rotational movements

are occurring for buildup of the weld pool). In the individual sectors, the respective current sector is highlighted in

white, and the accompanying red indicator indicates the current electrode position. The current sector number and cur-

rent position (in angular degrees) appear in the bottom section of the graphic.

Info field:

The following information appears in the info field (below the graphic): Name of the folder in which the proce-

dure is saved, name of the running procedure, current measurement values for water flow (in L/min), water temperature

and inverter temperature (in °C); current mains voltage (in V).

Warning messages and error messages appear in the "Warning" field.

The info field only appears during a running welding process.

Other:

The following information appears on the two bottom lines: Help texts for operation with the rotary knob; on the

right, information on the activated printer and the memory card (diskette symbol). When the printer is activated (e.g. log

printing after welding) or the card is activated (procedure being loaded), the symbols are highlighted in red.

Softkeys:

The current assignment of the softkeys appears at the bottom edge of the display. During the welding pro-

cess, only softkeys 1 and 2 ("Stop" and "Final slope") are active.

Ending the welding process

The following steps are carried out automatically at the end of the welding process:

• Current is automatically sloped off to the programmed final current.

• The arc is extinguished.

• Gas flow and water cooling are deactivated after the programmed time expires.

• Machine switches to ready-to-start condition.