ORBIMAT CA

| Operating instructions

Operation

(09.03.15) OW_ORBIMAT_CA_BA_871060202_04_EN

orbitalum tools

GmbH, D-78224 Singen, www.orbitalum.com, Tel. +49 (0) 77 31 792-0

43

properly when the wire extends 2 - 3 mm (0.079" - 0.118") from the feed tube after retraction. If the time is too long, the

wire is pulled in completely and the end (which is usually still a liquid ball) can adhere to the wire feed tube.

Wire HP/LP Speed:

The wire feed speeds of the filler wire (in mm/min) in the individual sectors. Auto programming usually

controls the wire in sync with the pulse: The wire feed motor does not move on the low pulse, as the energy of the arc may

not be sufficient to melt the wire under certain circumstances here.

To achieve a higher deposition rate:

X

Increase speed of the wire in the high-pulse phase.

– or –

X

Feed wire in the low-pulse phase as well. The weld current set for low pulse must be sufficient here.

1. In the main menu, select "

Manual/Adjust programming

" > "

Adjust parameters

" > "

Pool formation

".

2. Select, highlight, adjust and save the "

Wire start delay

", "

Wire final delay time

", "

Wire retract

" parameters.

3. Select"

go forward to sector 1

" or select the desired sector.

The respective selected sector is highlighted in color to the right in the display. The angular degree of this sector is

specified. An image of the seam scale appears below the process graphic.

4. Select, highlight, adjust and save the "

Wire HP Speed

" and "

Wire LP Speed

" parameters.

5. Press soft 1 ("

Weld

") or softkey 2 ("

Test

").

The machine is ready to start.

8.3.10

Changing the sector

Auto programming divides welding into different sectors (usually four to six). The parameters can be programmed for

each sector.

The sector borders can be shifted manually, and sectors can be added or deleted.

Adjusting sector borders with the rotary knob

1. In the main menu, select "

Manual/Adjust programming

" > "

Devide into levels

".

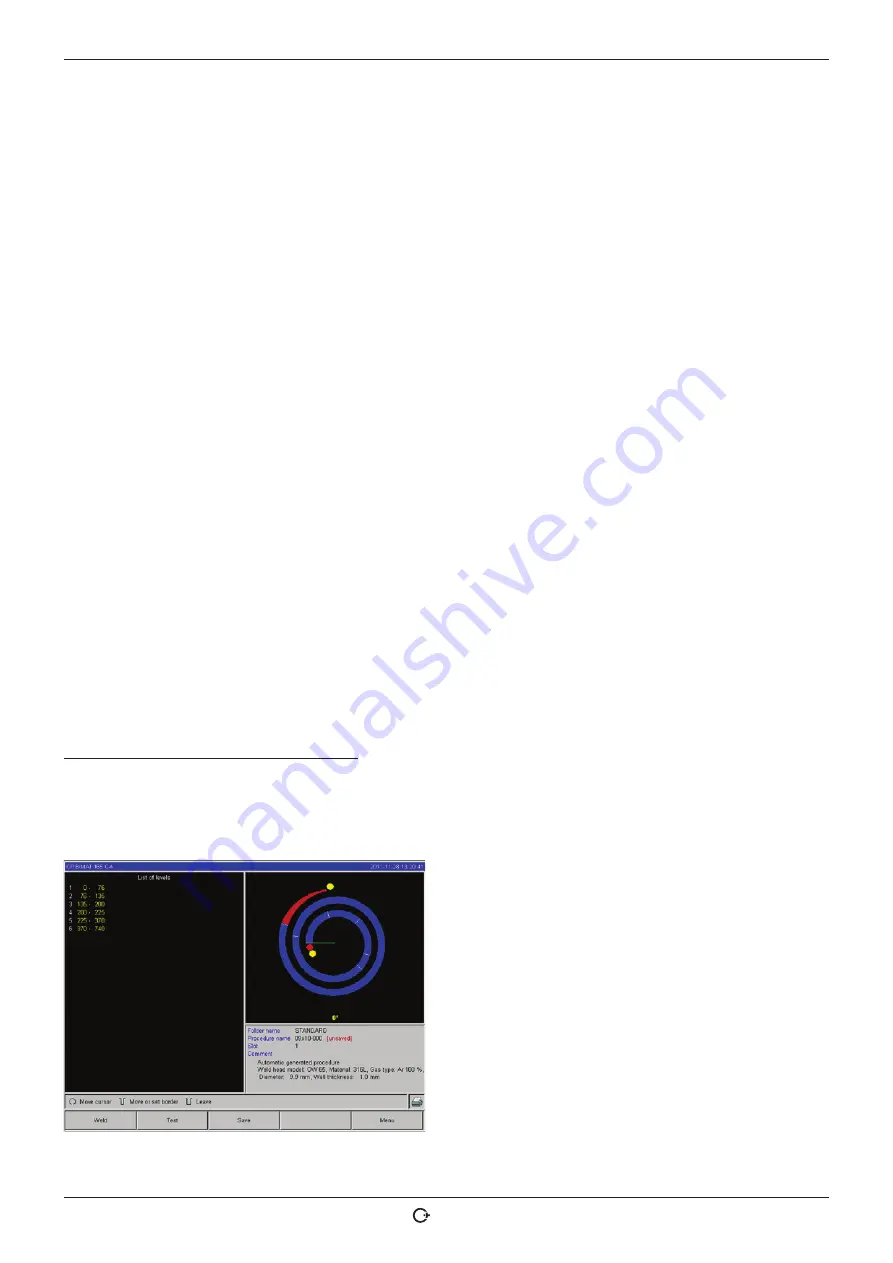

The sector list appears on the left in the display (five sectors in the example, see Fig. 22). The process sequence ap-

pears on the right.

2. Turn rotary knob until the pointer points to a white

sector border.

The green pointer moves through the sector, and the

degree information of the position appears at the bottom

edge of the process representation.

3. Ensure that the pointer is positioned correctly. For

this purpose, compare value in the sector list (end

sector 1 = 90°) with the degree information.

4. Briefly press the rotary knob.

The sector border is displayed in green.

Fig. 21:

Sector list - Pointer position for 90°