Service and troubleshooting

ORBIMAT CA

| Operating instructions

76

orbitalum tools

GmbH, D-78224 Singen, www.orbitalum.com, Tel. +49 (0) 77 31 792-0

(09.03.15) OW_ORBIMAT_CA_BA_871060202_04_EN

9.5

Temporarily deactivating sensors and monitoring functions

9.5.1

Sensors

Certain sensors can be deactivated temporarily. This can make sense, for example, when a defective gas sensor is present

and work is to continue. Greater attention is required when working with the machine.

The sensors cannot be deactivated permanently: Deactivation of the sensors for gas and water monitoring is reset each

time the machine is switched off. The sensor is active again after the machine is restarted.

9.5.2

Monitoring limits

The use of monitoring limits can also be deactivated.

9.5.3

External input for aborting

If an external device with the abort function is connected (e.g. residual oxygen meter), the function must be activated

so that the abort signal is processed by the unit in the machine. If an external device is not connected, the function

must be deactivated.

X

When deactivating sensors and monitoring limits, be aware that the corresponding monitoring function is no longer

active.

Example: With the gas sensor deactivated, the welding process is no longer interrupted if the gas bottle is empty.

X

Deactivate sensors only in cases where this is absolutely necessary.

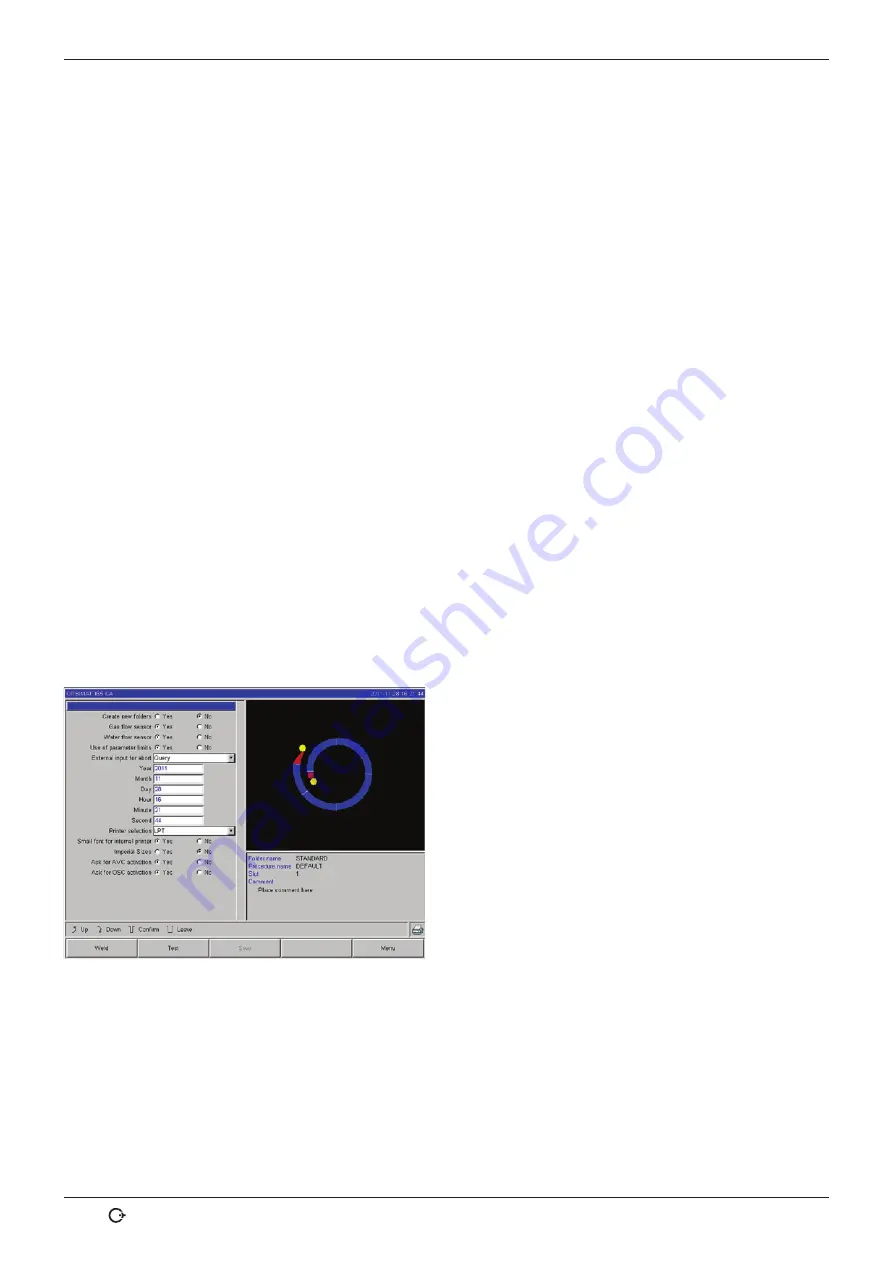

1. In the main menu, select "

System settings

" > "

System adjustments

".

The following display appears:

2. Select the "

No

" option for "

Gas flow sensor

"/"

Water

flow sensor

" for deactivation.

3. Select the "

No

" option for "

Use of parameter limits

"

for deactivation of the warning messages and process

aborting.

4. Select the "

Yes

" option for "

External input for abort

"

and connected external unit.

5. Press softkey 3 ("

Save

").

Fig. 37:

System adjustments