[REV. 20200320] OC_PS_BA_790048761_00__INH-02_EN

Orbitalum Tools GmbH

D-78224 Singen www.orbitalum.com

47

PS 4.5 PLUS

Transport and assembly

eNGLISH

7.1

Positioning the machine in the durable storage and shipping case

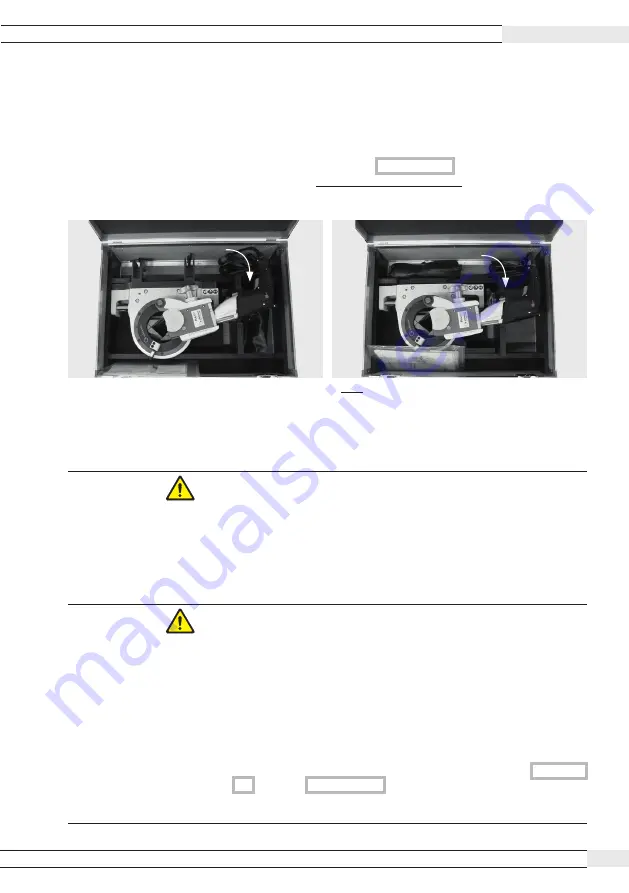

For a safe transport, the PS 4.5 Plus should be positioned in the durable storage and shipping case as shown in the two pictures

below:

1.

Turn the motor 90° on its own axis in the direction of the locking handle (see chap. 9.3, p. 60).

2. The vice (with or without quick mounting plate) should lie parallel to the length side of the case in the wooden enclosure.

3.

The slide housing with motor then should be rotated approx. 70° sidewards, so that it fits into the case enclosure.

70°

70°

PS with quick mounting plate

PS without quick mounting plate

8. TRANSPORT AND ASSeMBLY

WARNING!

When switching the motor on, the machine may revolve around the tube

automatically!

Diverse physical injuries and material damage.

X

In their home position, the saw blade must

not

touch the tube.

X

Make sure that the slide housing is in the home position when the cutting process starts.

X

Clamp the tube to be cut into the vice.

X

Before switching the motor on, make sure that the gap between the saw blade and the

tube is sufficient, and that the tube is securely clamped in the vice.

X

Place sufficient tube supports under the tube.

WARNING!

Flying parts/breaking tool!

Diverse physical injuries and material damage.

X

Do

not

process the tube while it is loose in the vice.

X

Never

use a damaged or deformed saw blade.

X

In the event of tool breakage with a new tool, do

not

enter the old cut because the tool

can break again.

X

Clamp the tube to be cut into the vice.

X

Immediately replace worn-out tools.

X

Ensure that the cutting tools are correctly fitted.

X

Tube dimension must be set correctly. During cutting, the saw blade must saw through

the entire tube wall.

X

Avoid breaking tool through low (adequate) feed force, correct dimension (see chap. 8.7,

p. 55) and speed (see chap. 8.8, p. 56) settings.

X

Hold on to the motor unit tightly by the handle, and guide it with low (adequate) feed

force during the machining process.