Page 37

Operation and Maintenance Instructions

Envistar Top 04-21

DSET.181201.00.EN

Continuous product development may give rise to specification changes without notice.

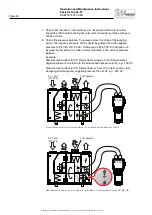

6.4 Counter-flow exchanger (code ATMM)

The purpose of the counter-flow exchanger is to recover heat

from the extract air and transfer this heat to the supply air in

order to minimise energy use.

Faults in counter-flow exchanger functionality reduce recovery

efficiency and increase energy consumption. The projected

supply air temperature will not be reached when outdoor tem-

peratures are low.

Possible reasons for reduced recovery efficiency could be the

fouling of the heat-exchanging surfaces (fins) or that the by-

pass damper is not closing completely.

A reduction of the extract air flow, e.g. due to fouling of the

extract air filter, entails reduced heat recovery efficiency.

Inspection

1. Shut down the unit via the service switch in the control equipment, safety

switch in the 0 position.

NB:

The safety switch is not designed for starting/stopping the unit. Always

use the control equipment to start and shut down the unit.

2. Wait until the fans have stopped, then open the inspection door.

WARNING!

Positive pressure inside the unit, risk of personal injury. Allow

the pressure to drop before you open the inspection doors.

3. Inspect the fins for fouling.

4. Perform a visual inspection of the automatic defrosting dampers and damp-

er motors.

5. Check that the bypass damper is tightly shut when defrosting is not taking

place.

6. Check the waste oulet and water trap function. A water trap without a non-

return value should be filled with water.