installation directiVe

4

MAY 2006

N40 ENT M25

N60 ENT M37-M40

19. FIRST ENGINE START

Before starting the engine, please make sure the sea water

gate valve is open, check the levels of the lubricating oil and

of the engine coolant, and complete venting the air from the

fuel feed loop, acting on the hand pump of the pre-filter or

with the aid of a dedicated electrical pump.

Loosen the vent fitting on the pre-filter and operate the

pump until only fuel without air flows out.

Tighten the vent fitting and continue pumping during the

initial start-up phases.

Make sure that the fuel that flows out of the fitting is not

dispersed in the environment.

CAUTION

never attempt to vent the high pressure system, as this is

useless and extremely dangerous.

Start-up procedures

The electrical equipment of this engine allows to start it from

the “engine room” and from the “bridge”.

NOTE

a few moments after start-up, make sure sea water is cor-

rectly drained from the relevant circuit.

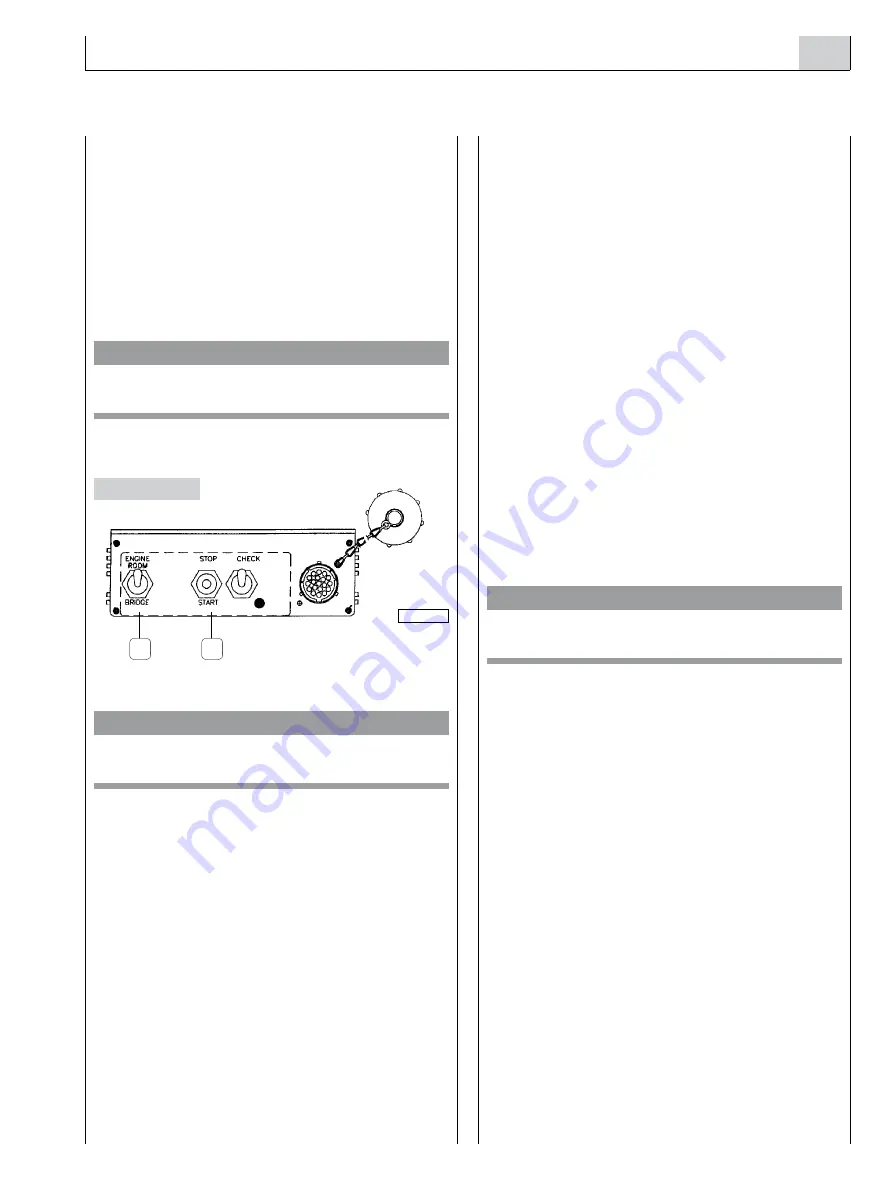

starting the engine from the bridge

This is allowed only if the Relay box switch (1) is in the

“BRIDGE” position.

Start the engine and let it run until the idling rpm has fully

stabilized (see also the Chapters on the instrument panels).

starting the engine from the “engine room”

Moving the Relay box switch (1) to the “ENGINE ROOM”

position (which must absolutely not be done when the

engine is running), regardless of the position of the key

switch on the indicator and control panel, enables the use of

the adjacent STOP - START push-button (2).

It will thereby be possible to start and stop the engine with

complete independence from the bridge controls.

Moving the switch (1) back to the “BRIDGE” position, inhib-

its use of the “START-STOP” push-button positioned on

the Box, allowing the engine to be started only from bridge

controls.

RPM control

To allow easily to control engine RPM from the “engine

room”, a simultaneous acceleration/deceleration function

(SET+/SET-), active only when the switch (1) is in the

“ENGINE ROOM” position, has been implemented in the

“start” function.

acceleration (set +)

If, when the engine is running, the “start - stop” push-button

is held down in the “start” position, then engine rpm are pro-

gressively increased; the increase ends when the push-button

is released, allowing the engine to run at the desired rpm.

deceleration (set –)

Moving the “start - stop” push-button back to the “start”

position, after releasing it during the rpm increase phase, a

progressive reduction in rpm is obtained; when the push-but-

ton is release, the function is inhibited and the rpm reached

at that point is maintained.

note:

Further action on the push-button will alternatively

increase - decrease engine rpm.

The “stop” function takes priority and always stops the

engine.

CAUTION

never operate the “bridGe - enGine room” switch

when the engine is running.

Once the first start-up phase is complete, verify that:

o

There are no liquid leaks from the coolant loop pipeline

junction hoses.

o

There are no exhaust gas leaks into the hull.

o

Complete the instrument panel operation tests as

described in the related Chapters.

o

Verify that the power supply voltage across the battery,

after about 15 minutes with the engine running, is no

less than about 13 V.

o

Stop the engine and delete any “errors” which may have

been stored in the injection system ECU during the

stabilization phases. For the deletion procedure, refer to

Chapter 20.

2

1

04_074_N

Figure 4

Summary of Contents for NEF N40-ENT-M25

Page 64: ...INSTALLATIONDIRECTIVE 64 N40 ENT M25 N60 ENT M37 M40 MAY 2006 ...

Page 69: ......