- 19 -

Remarks

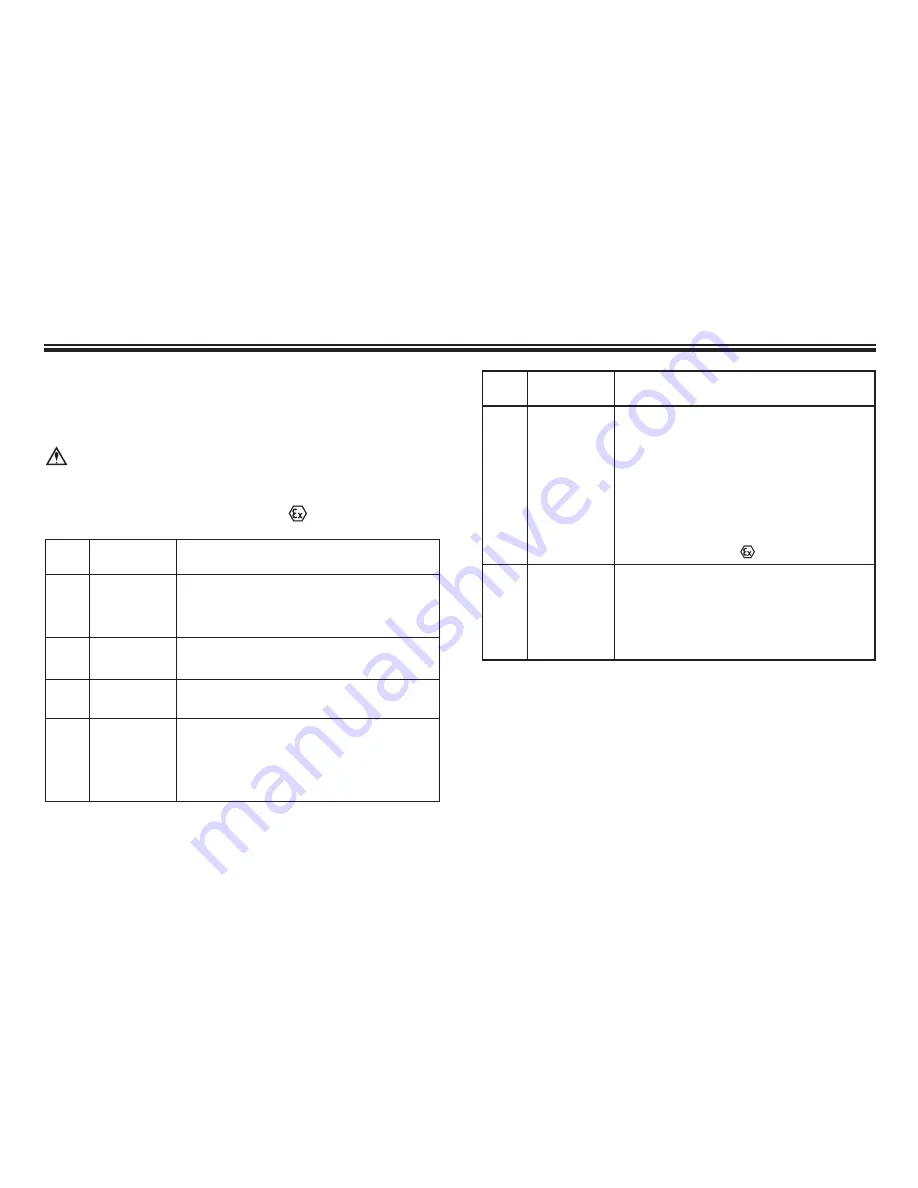

11. Operation

Item

Remarks

No.

Confirmation of

piping, wiring,

and voltage

Confirmation of

valves

Confirmation of

liquid in pump

Starting up

●

Confirm piping and electrical wiring, referring to

descriptions in piping and wiring sections.

●

Confirm that line voltage is appropriate, referring

to nameplate.

●

Valves on suction side and discharge side should be

fully opened.

●

When pump is used by priming method, prime

pump sufficiently.

●

After confirming items 1~3 above, turn ON pump

power supply, then check whether liquid is being

fed smoothly. If not, immediately turn off power

supply and eliminate cause of problem, referring to

"Causes of Trouble and Troubleshooting" section on

page 21.

1

2

3

4

Item

No.

Operation

During opera-

tion

●

Adjust valve gradually to obtain specified values of

discharge, discharge pressure, or vacuum.

●

Do not open/close suction port and discharge port

suddenly. This may lead to disconnection of mag-

net coupling, so that gears cannot rotate. If this

happens, turn off power supply. As motor stops,

normal coupling will be restored.

●

Do not operate pump with discharge valve and/

or suction valve completely or almost completely

closed. Set operating pressure to at least 0.1MPa

lower than set value of relief valve pressure in case

of MDG-R2( )V type.

●

Be careful not to allow any foreign matter to enter

pump. Foreign matter may cause gear locking or

abnormal wear of gear.

●

If earth leakage breaker is actuated, reset it only

after carefully examining cause of actuation. Be

sure to turn off power supply before examining

cause.

5

6

11-1. Operation

After pump installation, piping, and wiring, follow the start-up pro-

cedure described below.

CAUTION!

Never operate the pump dry or operate the pump with the

discharge and/or suction port closed (with the valve closed).

Such an operation damages the pump.