1. Troubleshooting

Caution

Before working on the pump, disconnect the power cord,

depressurize the discharge tubing and drain or flush any

residual liquid from the pump head and valves.

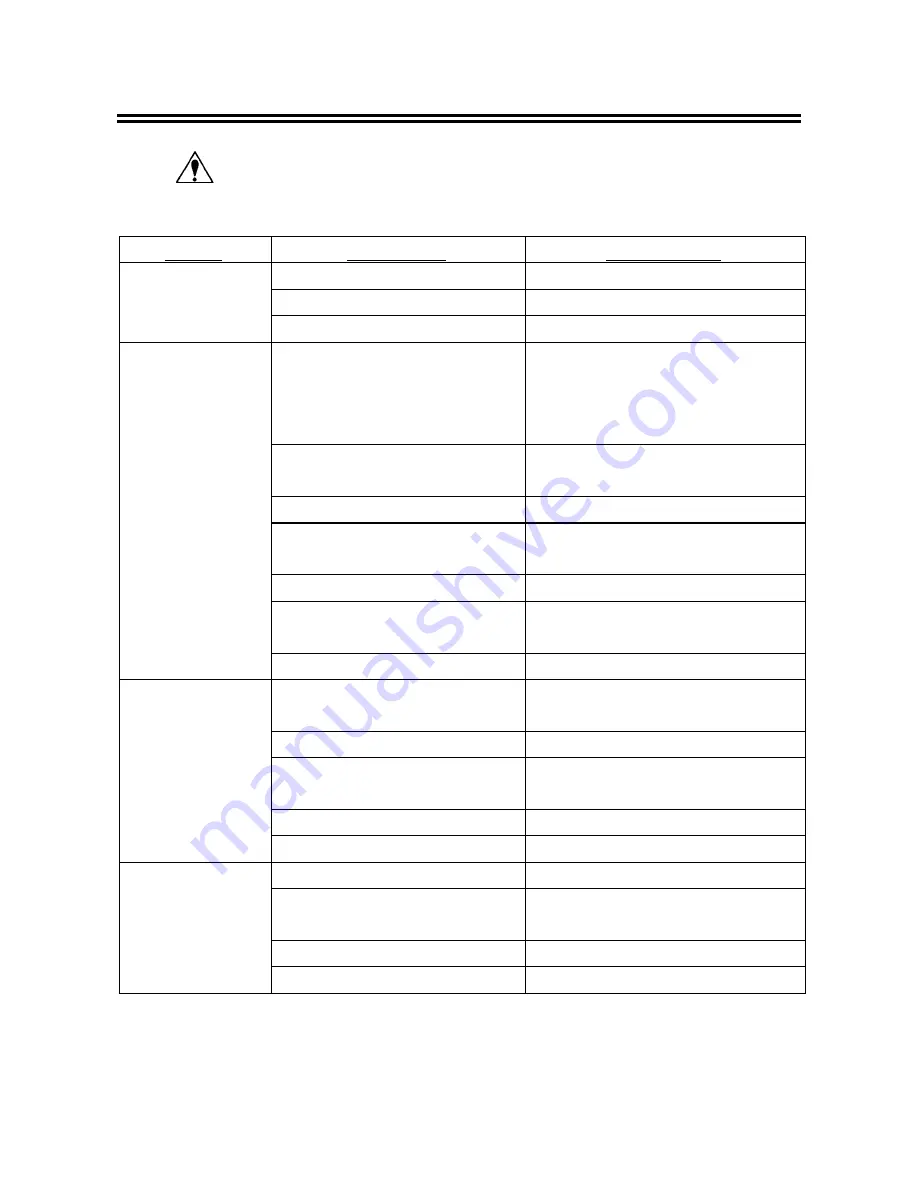

Problem

Possible Cause

Corrective Action

Faulty wiring

Correct wiring

Improper voltage

Connect to proper voltage source

Pump does not start

Electronic control unit is damaged

Replace control unit

Pump stroke length is too short

Operate pump with stroke length set at

100% until primed. Then set stroke

length as needed to obtain desired

output.

Air in suction tubing

Reroute suction tubing to eliminate air

trap

Valve gasket is missing

Install valve gasket

Valve set assembly direction is

wrong.

Reassemble valve set

Pump is air locked

Prime pump per instructions

Suction or discharge valve is

clogged with foreign matter

Disassemble, inspect, clean

Pump does not

prime

Ball stuck to valve seat

Disassemble, inspect, clean

Suction or discharge valve is

clogged with foreign matter

Disassemble, inspect, clean

Air is trapped in pump

Prime pump per instructions

Overfeeding

Install injection valve or back

pressure valve

Diaphragm is damaged

Replace diaphragm

Output fluctuates

Worn check valves

Replace valve cartridges

Liquid leaks

Fitting or coupling nut is loose

Tighten

Pump head is loose

Tighten pump head bolts

Torque: 2.6 N.m

Diaphragm is damaged

Replace diaphragm

O-ring or valve gasket missing

Install o-ring or valve gasket

- 36 -

Summary of Contents for EH-E

Page 12: ...5 Dimensions Material symbol VC V6 PC VM FC 10...

Page 13: ...5 Dimensions Material symbol VC V6 PC VM FC 11...

Page 14: ...5 Dimensions Material symbol SH 12...

Page 15: ...5 Dimensions Material symbol SH 13...

Page 33: ...5 Names of Part and Structure 1 Pump Head Unit Material symbol VC V6 PC P6 VM FC 31...

Page 34: ...5 Names of Part and Structure 2 Pump Head Unit Material symbol SH E30 E35 E45 32...

Page 35: ...5 Names of Part and Structure 3 Pump Head Unit Material symbol SH E55 33...