EN

3-4 Detailed Welding Procedures

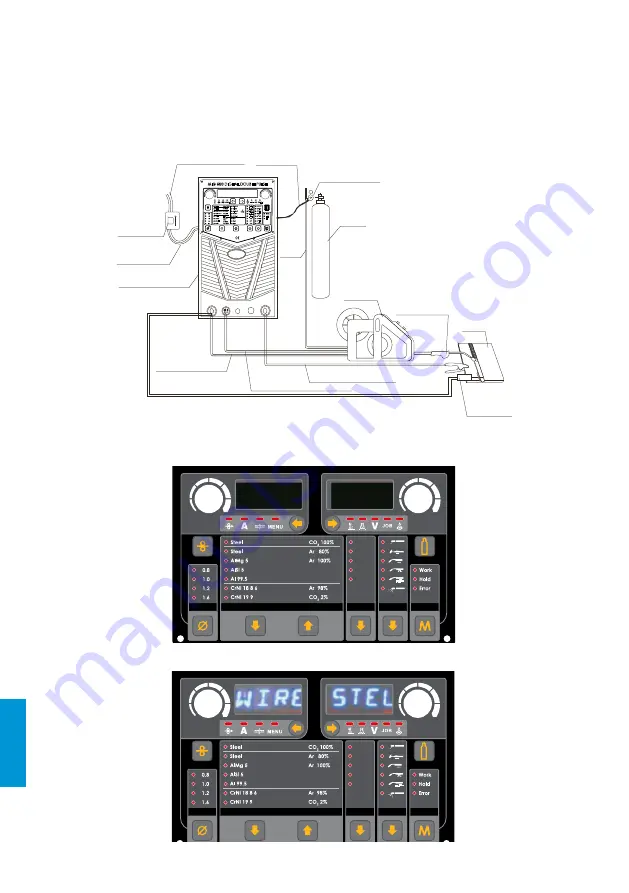

Take the following PMIG operating mode with 1.2 mm welding wire of carbon steel

for example.

Connect the welding source, wire feeder, workpiece and MIG welding torch accord

-

ing to the following procedures, as shown in the figure below::

Pressure regulator

Gas cylinder

Wire feeder

Heating line

3-phase power

supply 380V

Gas

path

Weldin cable (

-

)

Welding torch

Workpiece

MMA

welding

MIG welding

cable (+)

Welding machine

Input cable

Control box

Control cable of wire feeder

● Select the welding function by pressing the PMIG function key, as shown in the fol

-

lowing figure:

● Select the welding material. Press the S1 key to select MENU, and rotate the left

knob to WIRE and right knob to STEL, as shown in the following figure:

Steel

CO

2

100%

Steel

Ar

80%

AlMg 5

Ar 100%

AlSi 5

Al 99.5

CrNi 18 8 6

Ar 98%

CrNi

19

9

CO

2

2%

0.8

1.0

1.2

1.6

Work

Hold

Error

2T

4T

SPOT

S2T

S4T

Steel

CO

2

100%

Steel

Ar

80%

AlMg 5

Ar 100%

AlSi 5

Al 99.5

CrNi 18 8 6

Ar 98%

CrNi

19

9

CO

2

2%

0.8

1.0

1.2

1.6

Work

Hold

Error

2T

4T

SPOT

S2T

S4T

13

12