iWorX CCU1

505-022, Effective: September 23, 2010

17

© 2010 Taco Electronic Solutions, Inc.

To prevent the integral component from becoming too large, there is anti-wind up reset protection. This protection

clamps the integral value when all of the components add up to more than 100% or less than 0%. The following equa-

tions are used for P+I control:

K

P

= Proportional Gain

K

i

= Integral Gain

Error

=

Inputs

-->

Cond Rtn Temp

-

All Settings --> Cool Tower Valve SP

I

=

I

+ (

K

i

x

Error

)

Outputs --> Cooling Tower Valve (%)

= (

K

P

x (

Error

+

I

)) + 50.00%

The valve can be set for reverse action by exchanging the maximum and value settings during configuration. That is, if

the default maximum of 10 Volts and default minimum of 0 Volts are being used for reverse action, set the minimum to

10 Volts and the maximum to 0 Volts.

Cooling Tower Variable Speed Fan Control

The cooling tower variable speed fan is controlled when the CCU1 is configured for a water cooled chiller. The cooling

tower fan speed is calculated by a P+I control loop based on the condenser water return temperature and the cooling

tower water setpoint. The fan speed control loop is activated 15 seconds after the cooling tower bypass valve has mod-

ulated to its 100% position (full flow through tower).

As the temperature increases above the cooling tower water setpoint, the fan speed is increased. The fan speed is

decreased as the water temperature decreases below the

Chiller settings --> setpoint

. The fan speed control loop is

selectable for direct or reverse acting operation.

To prevent the integral component from becoming too large, there is anti-wind up reset protection. This protection

clamps the integral value when all of the components add up to more than 100% or less than 0%. The following equa-

tions are used for P+I control:

K

P

= Proportional Gain

K

i

= Integral Gain

Error

=

Inputs

-->

Cond Rtn Temp

-

All Settings --> Cool Tower Valve SP

I

=

I

+ (

K

i

x

Error

)

Outputs --> Cooling Tower Fan (%)

= (

K

P

x (

Error

+

I

)) + 50.00%

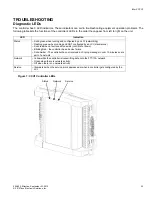

Figure 6: Cooling Tower Sequence

0%

100%

Condenser Return

Water Setpoint

Tow

er

W

at

er

By

pa

ss

Va

lve

Co

ol

ing

To

we

r Fa

n

Supply Water Temperature

The valve can be set for reverse action by exchanging the maximum and value settings during configuration.

Chiller Low Limit Control

The CCU1 provides low limit control. When the outside air temperature drops below the low limit setpoint as sensed by

the ASM on the network, the CCU1 energizes the chiller low limit output and starts the chilled water pump. The chiller

low limit output is interfaced to the factory supplied chiller controls to signal the chiller to not start in response to the

chilled water pump operation in the low limit condition. The chilled water pump and chiller low limit output de-energizes

when the temperature rises 1 °F above the low limit setpoint.