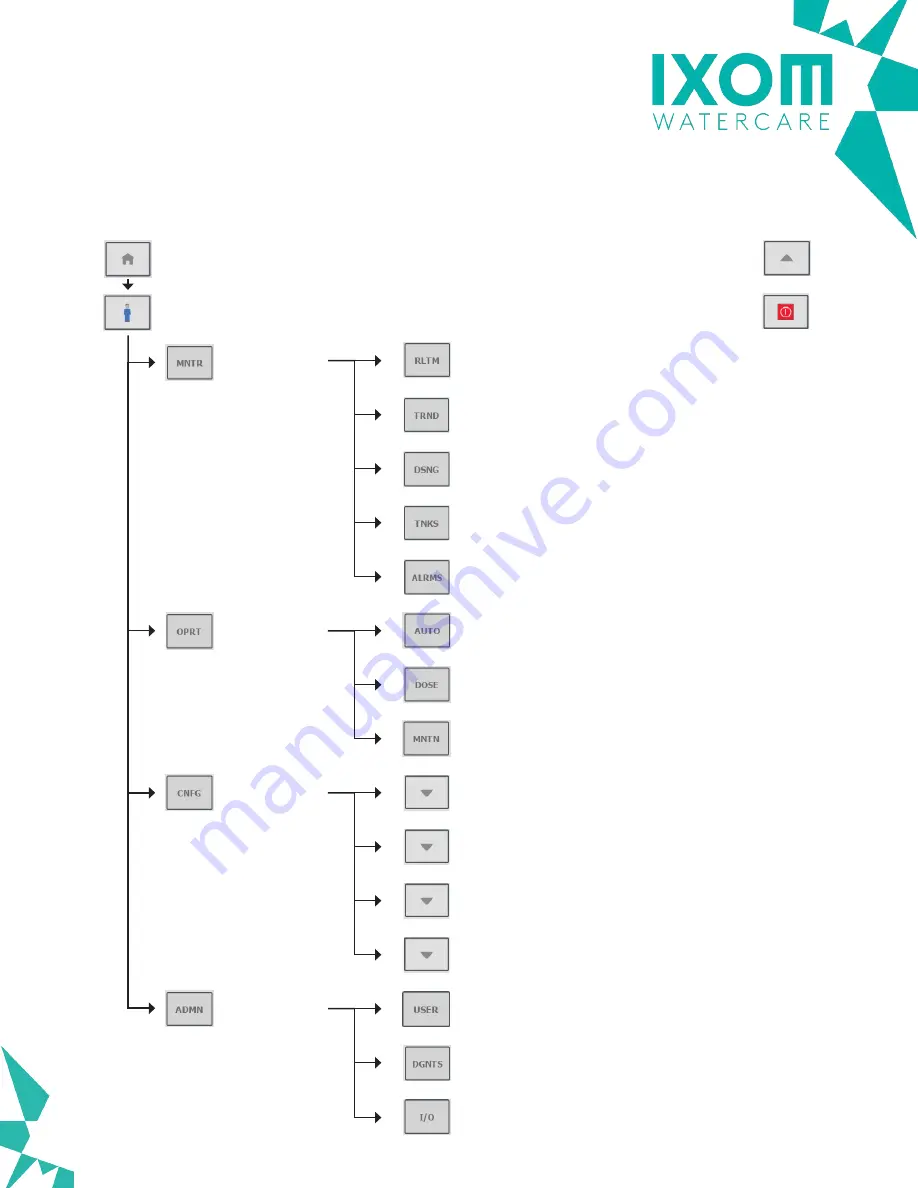

Real-Time Values

Chlorine Residual Trend

Recent Dosing Information

Monitored Tank and Bulk Storage Levels

Alarm Log (Warnings and Errors)

Automated Management Mode Control

Manual Dosing Mode Control

Maintenance Mode Control

System Configuration

General Operation Parameters

Automated Management Parameters

Trending and Historical Data Parameters

User Administration and Runtime Control

Controller Diagnostics

Home

Login

Monitor

Operate

Configure

Administration

Navigate Back

Stop Circulation

Controller Input/Output Monitor

©2022 IXOM Watercare Inc. | www.ixomwatercare.com | 866 - 437 - 8076 | watercare@ixom.com

Menu

Menu Layout

Overview

10358_20220119

ControlManual_ResidualHQ_10380_20220809a - 6