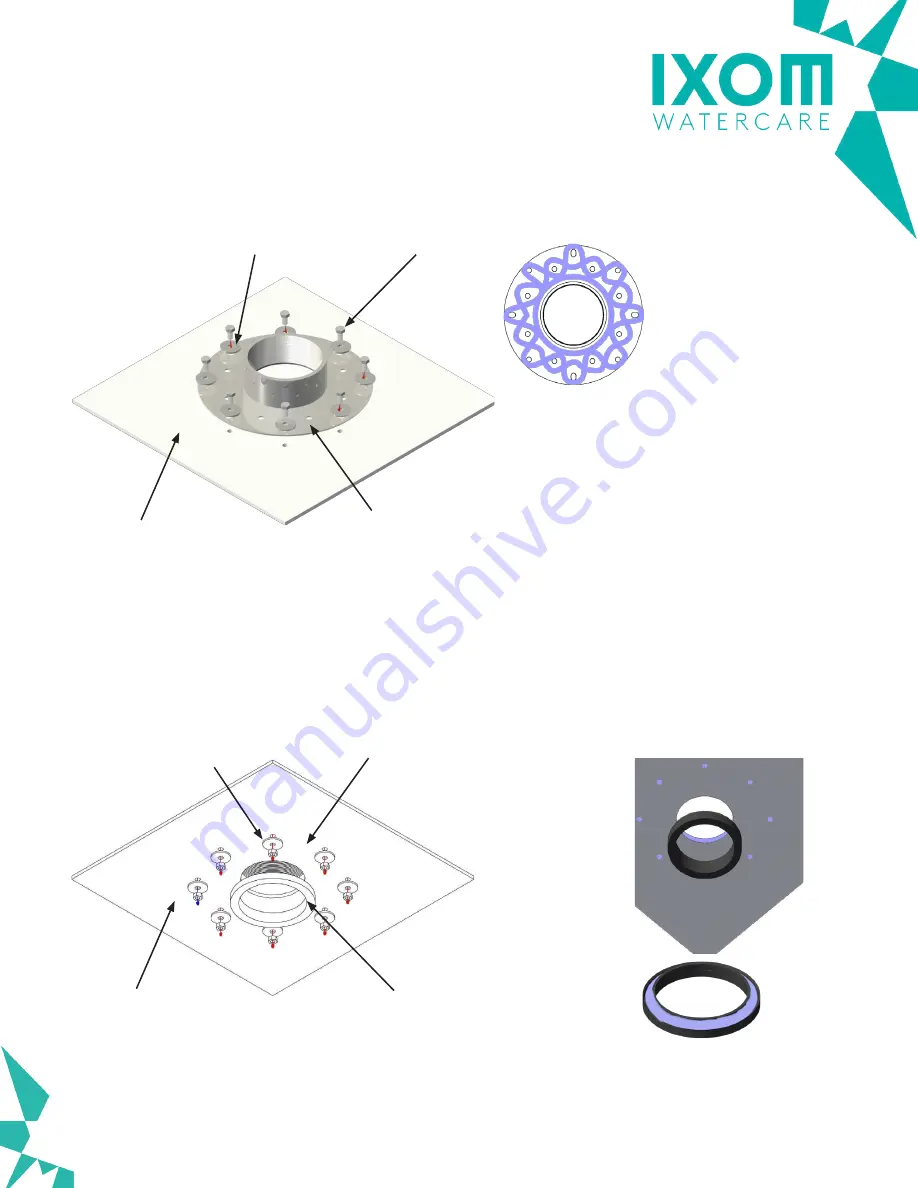

Figure 1:

Outside Tank Bolt Installation

Figure 2:

Inside Tank Bolt, Gasket and Flange Installation

Sheet Roof

Structure with Penetration

Hole and Bolt Holes

4” Coupling Flange Assembly

with Lexel Sealant

(See Inset A for

placement of Sealant)

Sheet Roof

Structure with Penetration

Hole and Bolt Holes

Rubber Gasket

with Lexel Sealant

(See Inset B for

placement of Sealant)

Fender Washer with

Lexel Sealant

M8 Nylock Nut

Fender Washer

M8 Bolt

Inset A

Inset B

***

NOT DESIGNED AS A

SUBMERSIBLE PENETRATION

***

©2021 IXOM Watercare Inc. | www.ixomwatercare.com | 866 - 437 - 8076 | watercare@ixom.com

Integration

4" Coupling Flange Assembly

For Steel Roof Systems

1957_10046_20210428

O&M_SB2500PW_10248_20211110 - 22