To obtain a cappuccino with a lot of foam, we recommend to use a high and narrow container half filled with milk. Then

immerse the steam nozzle about 2/3 cm into the milk. If you just want to heat the milk, dip the steam nozzle to the bottom of the

container.

WARNING

: after using the steam, do not forget to close the steam tap by turning the knob in the clockwise direction and clean

the steam wand.

2.7

MAINTENANCE AND CLEANING

All maintenance and cleaning operations, in particular of the reservoir, must be carried out after disconnecting the electricity

supply.

A daily cleaning of the reservoir is necessary in order to avoid that the scale, that deposits at the bottom of the reservoir, could

be sucked up into the boiler, causing the block up of the electronic circuits.

This situation may block the functioning of the solenoid valve, as well as it may reduce the water flows in the pipes and

consequently in the group, affecting the correct coffee extraction.

For the cleaning use a common detergent or a water and vinegar solution. We recommend the use of non-aggressive detergents.

The filter holder and the filters must be cleaned by soaking them in a solution of water and sodium bicarbonate for 8 hours.

After that, you have to rinse them with running water.Check if the filter installed under the group head is encrusted with coffee.

In this case, remove the filter from filter holderand replace, temporarily, with the blind filter supplied with the machine. Lay on

the blind filter a spoon of detergent for espresso coffee machines and insert the filter holder under the brew head group. With the

machine ready for the use, raise the brewing lever, for about 10 seconds, and then lower it. Wait 30 minutes in order to allow the

dissolution of the impurities. Soon after, remove the blind filter from the filter holder. Let out only hot water through the lever

just enough to eliminate all dissolved impurities.

Clean the bottom of the tank and the housing of the float at least twice a month (Figure 4, page 5) in order to remove all the

scale deposits and avoid sudden malfunctions.

2.8

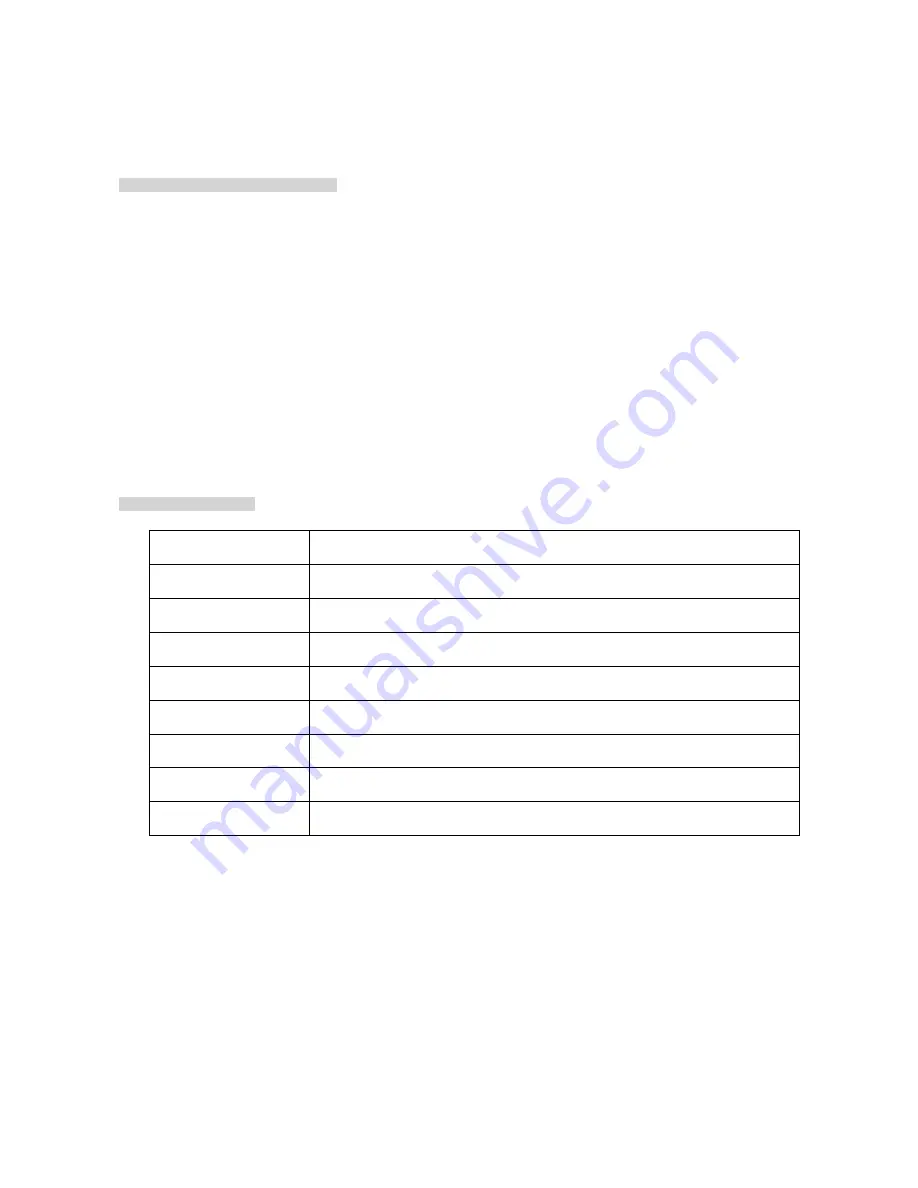

TECHNICAL DATA

Bodywork

Stainless steel (AISI 304).

Electronical control

Microprocessor for the automatic control of the water level into the boiler and warning about

the reaching of the minimum level of water into the reservoir.

Boiler

Dual-boiler system:1,8 liter shot water/steam boiler;0,8 liter coffee brewing boiler.

Pump

Super silent rotary pump.

Maintenance

Removable grid for an easy access to the lower components of the machine.

Safety valve

Certified safety valve.

Water supply

2 liters reservoir or, alternatively, direct connection to the water net by turning the control

switch. Liquids drain through a removable tray or directly into the sewer net.

Hot water and steam Taps

Taps with insulated stainless steel wands that avoid the user to be burnt during their use and

improve the performance of the steam.

Pressure gauges

One pressure gauge dedicated to the pump pressure and a second pressure gauge for boiler

pressure control.

19

Summary of Contents for Alex Duetto IV AUST. MK 606

Page 4: ...DESCRIZIONE DESCRIPTION 3...

Page 6: ...FIGURE ILLUSTRATION 5...

Page 7: ...SCHEMA ELETTRICO ELECTRICAL SCHEME 6...

Page 9: ...1 ITALIANO 8...

Page 16: ...2 ENGLISH 15...

Page 23: ...56 ReV1 1 del 22 12 2016 www mywayitaly com www alexduetto com...