November 5, 2015

21

Operating Instructions

Operate always with the door closed: keeping the door

open can cause runaway and overheat, and it might

damage permanently the stove or a chimney fire.

It’s recommended to install a co, co2 and smoke

detector in the room where the stove is situated.

Never hit the door.

Never burn inflammable liquid: inflammable liquid makes

uncontrolled heat and can make permanent damage to

the stove or a chimney fire.

Always verify if the air inlet is not obstructed before

lightning.

Never elevate fire with grate or andiron. Always make fire

directly on the hearth.

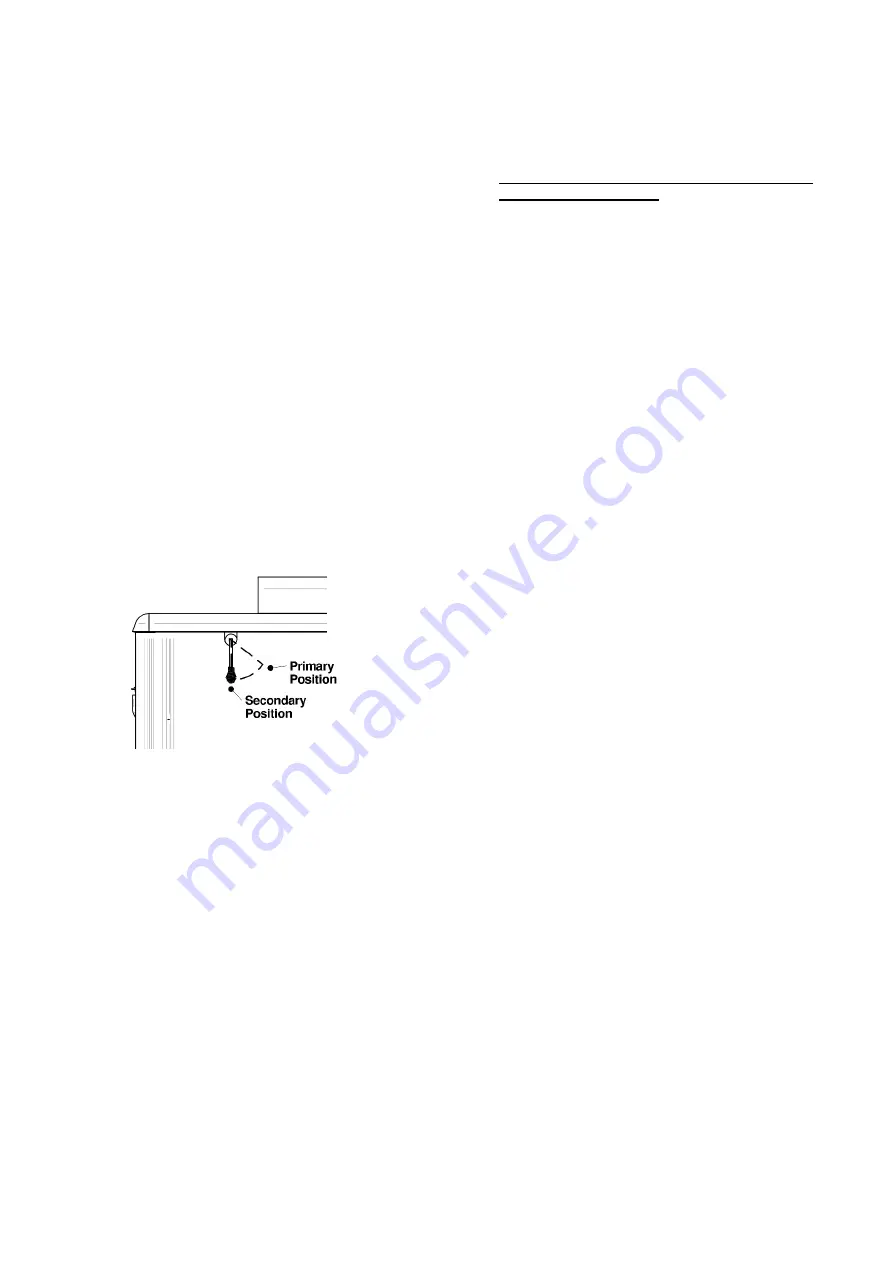

Primary and secondary air admission

control

When the handle on the left of the stove is vertical, the air

admission is only from the tube, this is what we call “Secondary

air admission”. When the handle is angled, the air admission is

direct and from the air intake above the door which is called

“Primary air Admission”.

Warning: Operating the stove with the Primary air

admission fully open for a long period of time can damage

the stove.

IT IS PROHIBITED TO MODIFY AIR ADMISSION TO

OBTAIN A HIGH HEAT OR ANY OTHER REASONS. ANY

MODIFICATION CAN AVOID GUARANTEE.

Lightning fire

After installing correctly the stove following the installation

instruction of the manufacturer, you are ready to light it.

1) Turn the admission handle in horizontal position to set

the primary air admission.

2) Put paper and lightning wood in the combustion

chamber and light the fire in your way.

3) Close partially the door keeping a slight opening.

When chimney have enough heat buildup, close the

door completely and lock it. Wait for a good fire

buildup.

4) Once you have an ember fire, it’s time to add logs.

Follow now the instruction section on how to keep a

fire.

DO NOT OVER CHARGE THE STOVE MORE THAN

THE UPPER BRICK ROW.

You can control the combustion by turning up or down the

handle. The wood will burn more rapidly when more primary air

is set. Otherwise the wood burn more slowly and more

efficiently with the handle set to secondary air.

•

NEVER LEAVE THE STOVE UNATTENDED WHEN

THE DOOR IS SLIGHTLY OPEN. ALWAYS CLOSE

THE DOOR AFTER LIGHTNING.

•

ALWAYS USE THE STOVE WITH THE DOOR

CLOSED.

•

DO NOT USE ANY CHEMICAL PRODUCT OR

INFLAMMABLE LIQUID TO LIGHT OR REKINDLE

THE FIRE.

•

DO NOT BURN WASTE OR ANY OTHER

INFLAMMABLE PRODUCTS AS GASOLINE,

NAPHTHA OR MOTOR OIL.

•

DO NOT MAKE FIRE TOO CLOSE TO THE GLASS.

•

KEEP INFLAMMABLE PRODUCTS FAR FROM THE

APPLIANCE.

First fire

The first hours of operation, you must heat it gradually. In order

to allow an appropriate baking of the paint and in order to

facilitate its adhesion with metal, do not heat the appliance with

a strong fire. It will also avoid thermal shock which could lift up

the paint or make the color fade.

Make sure that the room is ventilated enough in order to

eliminate the odours and the smoke coming from the paint

during the first hours of usage.

Even if this nuisance is temporary, open the windows and the

doors in order to ensure a good ventilation. This special paint is

conceived to tolerate temperatures until 1200°F (650°C).

Keep a fire

To add firewood into the stove and keep a fire:

13) Turn the handle to horizontal position and wait a few

second to let the fire adjusting to the new conditions.

14) Open the door handle to the first position and wait a few

second to balance pressure to avoid fume to escape from

stove.

15) Turn the handle completely and leave the door half open

and leave the time so that the fire can adjust.

16) Open the door widely.

17) Move embers with poker near the door to oxygen it and

make it burned completely.

18) Add firewood over the ember, keeping it away from the

glass door to prevent the flame from touching the ceramic

glass.