April 28th, 2016

16

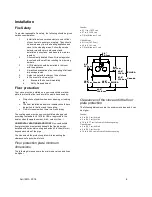

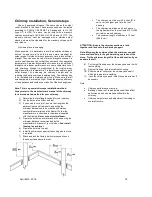

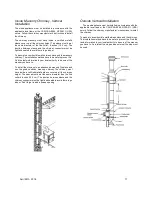

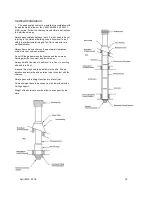

Chimney installation, General steps

Use only approved chimneys. The same size as the output

collar. 6 inches in this case. The chimneys used must be tested

according to CAN/ULC S629 M87 in Canada and to UL 103

(type HT) In USA. The stove can be install with a masonry

chimney according to ULC S635, ULC S640 and UL 1777. The

masonry chimney must be equipped with a stainless steel

sleeve and meet the standards for the masonry chimney with

inner sleeve.

Provide a place to sweeping.

When possible, it is preferable to avoid an outside chimney or

built on an exterior wall, and this is even more important for

colder areas. Outside chimneys generally have a less efficient

draught. They can even have an inverse draught because it is

hard to heat them enough so that they can reach their operating

temperature. A greater accumulation of creosote, a less efficient

draught and a lesser performance are some characteristics of

cold chimneys. Draught is proportional to the total chimney

height as well as its temperature. It is therefore possible to get a

better draught by increasing the chimney's height and by

reducing the heat loss with an insulated lining. The chimney has

to be installed with a stainless steel lining. Make sure that all

smoke pipe joints are really airtight. A leak reduces the efficiency

of the appliance and could even make its utilization dangerous.

Note: This is a general chimneys installation method.

Always refer to the manufacturer’s manual of the chimney

for a more detailed method for your chimney.

1) Determine the total length needed for your chimney..

2) Cut the holes into all floor and roof

3) If you need to cut a joist, be sure to strengthen the

adjacent joists and frame hole respecting the

minimum dimensions to be maintained between

combustible materials and the firewall. Follow the

manufacturer's instructions in the manual supplied

with the firestop. Never cut a structural beam.

4) Frame the holes in each level and attic respecting the

minimum distance recommended by the

manufacturer's manual of your chimney. And install

firestop in each level.

5) Frame the hole into the roof.

6) Install the chimney support at the ceiling where stove

is installed.

7) Stack and lock the factory built chimney section on

the support and above the roof.

•

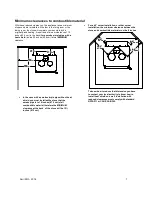

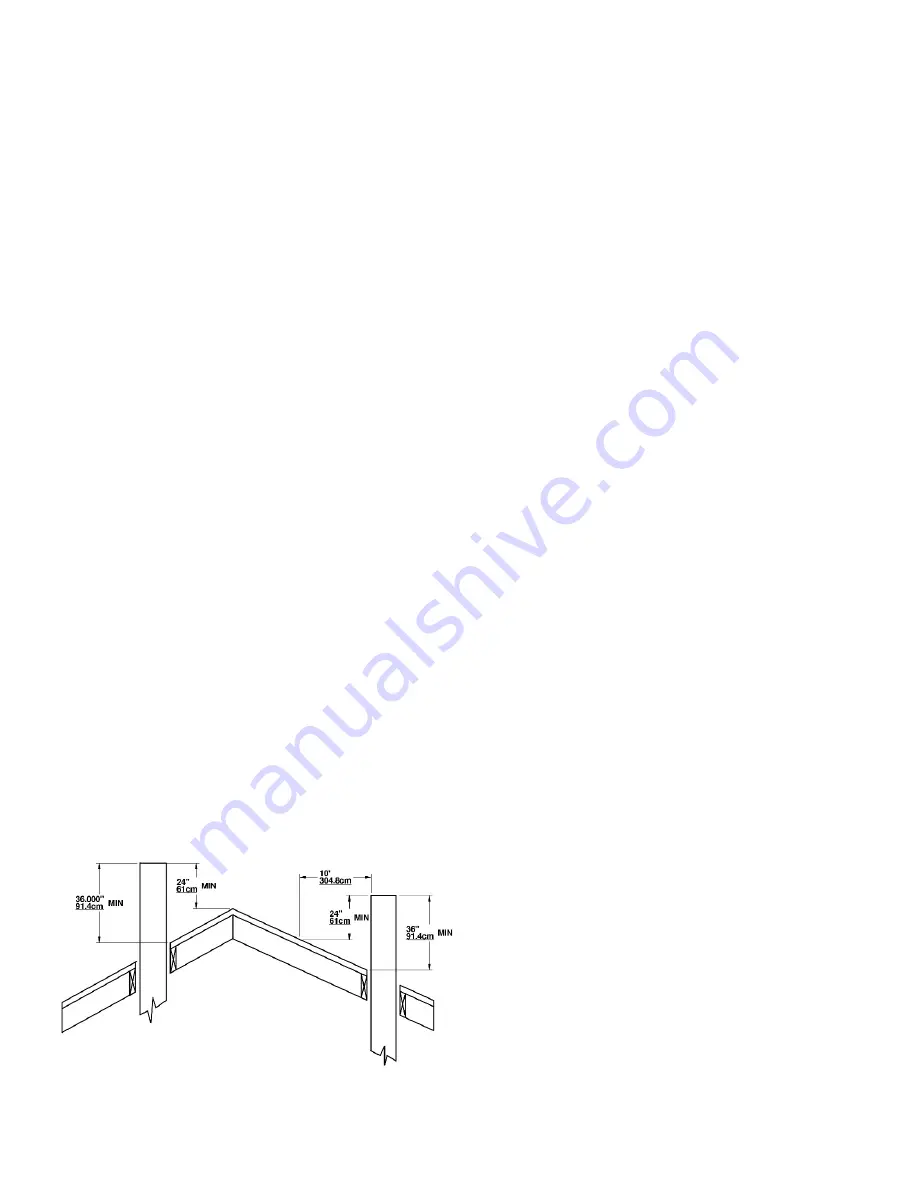

The chimney must be over 36 inches (91.4

cm) over the higher point into the roof

opening.

•

The chimney must also be 24 inches over

the highest point on the roof inside 10 ft (304

cm) radius around chimney.

•

The minimum length of chimney is 12 feet

(365.8 cm).

ATTENTION: Be sure the chimney section are lock

together and lock onto the chimney support.

Note: More lengthen chimney than the minimum can add

more draft and help to the good working operation of the

stove Try the minimum length first then add section if you

need more draft.

8) Put the roof flashing over the chimney and seal it with

roof caulking.

9) Nail roof flashing, and reinstall roof covering.

10) Slide the storm collar over the chimney and seal it

with high temperature caulking.

11) Lock the chimney cap and install the spark arrestor if

necessary

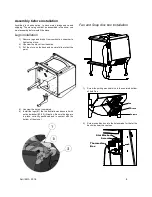

Note:

•

Chimney performance may vary.

•

Buildings, trees, roof line and wind conditions affect

performance, and can make backflow into the

chimney.

•

Chimney height may need adjustment if smoking or

overdraft occurs.

Summary of Contents for SIRIUS

Page 4: ...April 28th 2016 4 Nameplate...

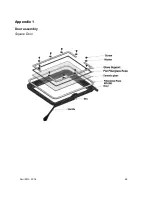

Page 26: ...April 28th 2016 26 Appendix 1 Door assembly Square Door...

Page 27: ...April 28th 2016 27 Arc Door...

Page 28: ...April 28th 2016 28 Appendix 2 Fans electric wiring diagram Therm O disk Box parts description...

Page 30: ...April 28th 2016 30 Appendix 4 Bricks dimension and quantity...