PR_I020/2023-08-11-EN

Revision: 5

15

Chimney connector installation

The chimney connector is a set of single wall or double wall

flue pipes and elbow installed between the stove collar and the

chimney collar. The single wall chimney connector is sold into

any hardware store and are not homologated and certified.

Some rules must be followed for installation and can be found

in the installation codes for wood heater.

•

Double wall chimney connector

The stove was designed and tested with a

single wall

chimney connector with heat shield,

but it is possible to

install a 6 inch (15.2 cm) double wall certified chimney

connector

ATTENTION: For the clearance between combustible

materials and double wall chimney connector, see

manufacturer

’s manual.

•

Single wall chimney connector

For the single wall chimney connector, you must use the

single wall or double wall chimney connector and it must be

6 inches diameter and have a minimum thickness of 24

gauge (0.025 in 0.64 mm).

For the single wall section and

elbow, install a metal heat shield and 1 inch (25.4 mm)

offset.

ATTENTION:

•

If heat shield is not installed, you must move away the

stove to keep 18 inches (45.7 cm) clearance between

combustibles materials and the chimney connector.

•

Any horizontal section must have a slope of 1/4 inch (6.35

mm) by feet (30 cm) toward the chimney collar. It should

not exceed 36 inches (91.4 cm).

•

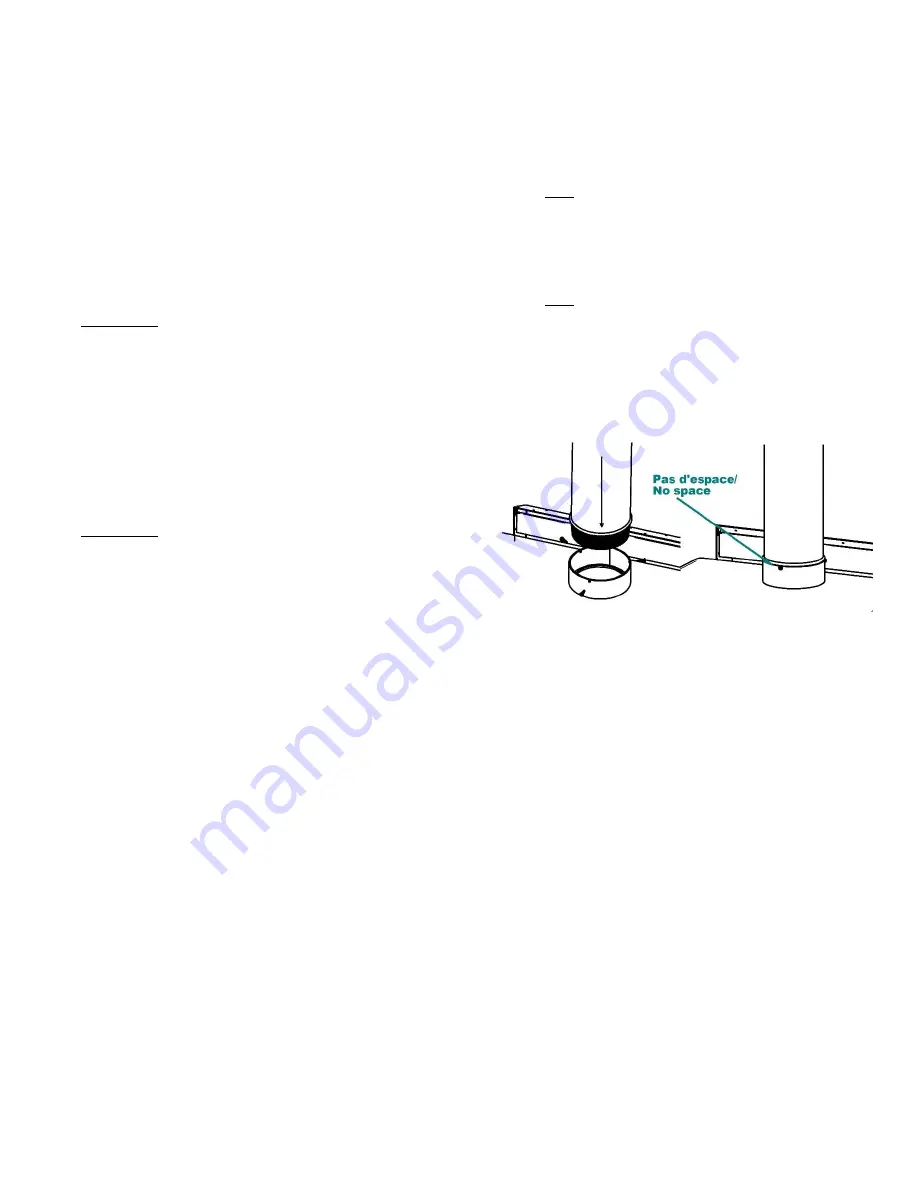

Clearance between roof and horizontal single wall

chimney connector must be 18 inches (45.7 cm) or more.

•

Clearance between roof and horizontal double wall

chimney

connector,

follow

chimney

connector

manufacturer indication.

ALL SECTION AND ELBOW MUST BE CLEAN AND IN

GOOD CONDITION AND MUST BE APPROVED FOR

WOOD BURNING.

1.

Chimney connector assembly installation

Make a summary installation of all sections and elbows (if

necessary) to ensure that you meet the clearances and

inclinations of the horizontal sections and check that you have

all the necessary parts to final installation.

o

For direct vertical installation you will need:

▪

1 adequate length of vertical section;

▪

1 adequate length of telescopic chimney

connector section allowing you to connect

the last chimney connector section to the

roof support collar.

Note: Additional sections can be used for higher roof.

o

For horizontal run installation, you will need

▪

1 adequate length of vertical section;

▪

1 x 90° elbow or 2 x 45°elbow;

▪

1 x adequate length of telescopic chimney

connector section.

Note: For better performance, two 45 degrees elbows

are preferable, with or without straight section in

between.

2. Disassemble the whole thing and start screwing the pieces

from the stove to the roof chimney collar.

3. Insert entirely the roll formed end into the stove collar and

fix it with minimum 3 screws

.

4. Install all the next section up to the roof chimney support

and screw every chimney connector parts with 3 screws

WARNING: It’s mandatory to screw all joint with a

minimum of 3 screw.

5. Install all other sections and screw them all up to the

chimney collar.

6. Screw the last section to the chimney collar.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE

SERVING ANOTHER APPLIANCE.

CONNECTOR PIPES SHOULD NEVER PASS THROUGH

THE CEILING, IN A WALL, IN A CLOSET, IN AN ATTIC

OR OTHER ENCLOSED AREA THAT COULD CAUSE

HEAT BUILDUP. IF YOU NEED TO PASS THROUGH

COMBUSTIBLE MATERIAL, MAKE SURE THAT YOUR

INSTALLATION COMPLIES WITH CAN / CSA-B365.

.

Summary of Contents for ULTIMATE TOR 2015

Page 4: ...PR_I020 2023 08 11 EN Revision 5 4 Rating plate...

Page 5: ...PR_I020 2023 08 11 EN Revision 5 5 Appliance Dimension...

Page 13: ...PR_I020 2023 08 11 EN Revision 5 13 Firebox configuration and part list...

Page 28: ...PR_I020 2023 08 11 EN Revision 5 28 Annex 1 Door assembly Square Door Arc Door...