P RO D U C T I N F O R M AT I O N

Page 11

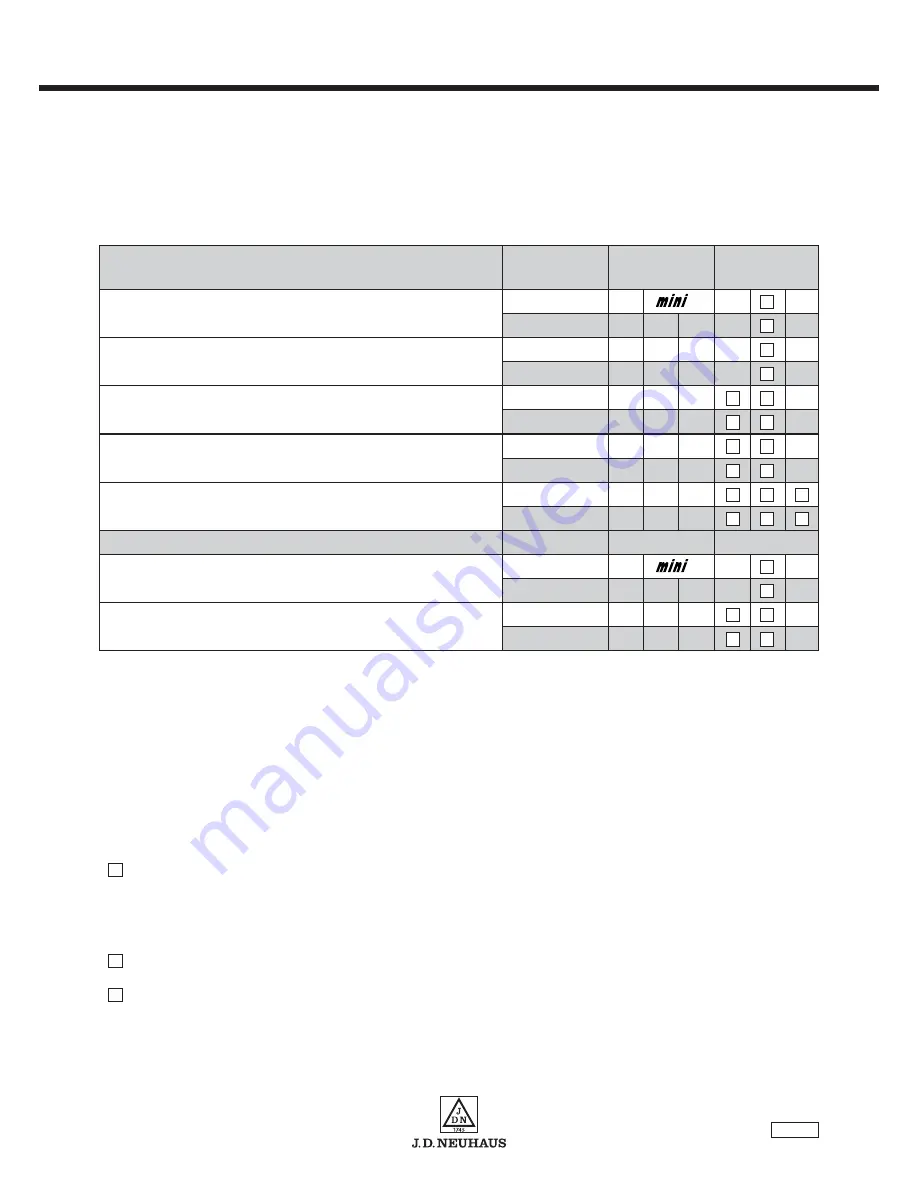

DECISION CRITERIA FOR SELECTING THE CORRECT JDN HOIS T S IN EXPLOSION-HAZARDOUS AREAS

Explosion groups of gases and vapours

Zone

Version*

1

Operation*

2

(cf. Explosion groups and temperature classes of the most important gases and vapours)

Manufacturer's responsibility

Operator's responsibility

II A

2

A

*3

1

A

II B (X)

except hydrogen sulphide, ethylene oxide

2

A

(particularly flammable)

1

A

FS

II B

2

A

FS

1

A

FS

II C / T4

2

A

FS

1

A

FS

FSR

II C / T6(X)

2

A

FS

1

A

FS

FSR

Explosion-hazardous dusts

Zone

Version*

1

Operation

*2

Usual industrial dusts

22

A

*3

21

A

Light-metal or impact-sensitive dusts

22

A

FS

21

A

FS

E

D

E

D

E

E

T

E

D

T

E

D

E

D

E

D

E

D

E

D

E

E

E

E

*1:

Version features (under the responsibility of the manufacturer):

A:

The chain is made of zinc-plated steel; metal controls are conductively connected to the hoist. This is part of

the standard equipment. For technological reasons, a zinc-plated version of chain size 31.5 x 90 is not available.

This is only used for the extremely slow-running chain drives of large hoists, so that the sliding velocity for

potential friction points between the chain and the surroundings remains well below 1 m/s.

SP: Hoists ˝with increased spark protection˝:

Copper-plated load hook and bottom block with brass safety catch.

FSR: Running gear ˝with increased spark protection˝:

Running wheels for trolleys and cranes are made of bronze.

*2:

Instructions for safe operation (operator's responsibility):

: Ignition hazards are not to be expected if hoists or cranes are used in the normal manner. Friction and impacts in

the working area of the chain, not resulting from intended use of the hoist or crane and which result in sparking,

must be excluded, or an absence of gas in the operating area must be ensured. This means, for example, that the

chain, the bottom block and the load hook must be prevented from swinging against surrounding objects or that

a gas-free environment must be ensured.

: Friction, impact and sliding points involving combinations of light metal and steel or cast iron must not be

present in the hoist's operating area.

: Ambient temperature and the type of operation must be examined separately.

*3:

Use of MINI type hoist:

Hoists of the mini type are not available with ˝increased spark protection˝ (FS).

T

E

D

powered by air !

Summary of Contents for JDN mini 1000

Page 47: ...powered by air NOTES Page 47 ...