A copy of the special publication ˝Recommended lubri-

cants˝ is available on request.

Hoists, including the supporting structure, must be

inspected by an appropriately trained and qualified

person before initial operation and before re-commis-

sioning after significant modifications. Hoists and

lifting gear which are installed in trolleys must be

inspected by a specialist.

The inspection covers the proper mounting, equipment

level and operational-readiness, in the main, the com-

pleteness, suitability and effectiveness of the safety

devices as well as the condition of the device, the

harness, the equipment and the supporting structure.

Safety devices are braking devices, overload protection

devices, EMERGENCY STOP devices, lifting and lowering

limiters (emergency end-stop devices).

A description of the inspection can be found in the

Maintenance

section, page 29.

CHECKING PRIOR TO INITIAL OPER AT I O N

powered by air !

I N I T I A L O P E R AT I O N

Page 22

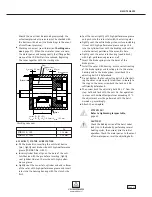

Application

Lubricant

Motor lubrication

- JDN high-performance

grease,

- from factory

Art. no. 11901 (250 ml)

- when operating with oiler

- Compressed air oil ˝D˝,

kinematic viscosity

approx. 30 mm

2

/s (cSt)

at 40° C, with anti-icing

agent where applicable

Chain lubrication

chain oil or motor vehicle

engine oil, kinematic

viscosity approx. 150 mm

2

/s

(cSt) at 40° C, or special

lubricant from J.D. NEUHAUS

In areas with very high

corrosion potential, e.g.

offshore, a lubricant with

extremely strong anti-corro-

sion properties must be used.

Motor conservation

Non resinous

(not applicable when using

Conservation oil with

JDN high-performance grease) appropriate period of

effectiveness

Motor cleaning

Pure petroleum

(not applicable when using

JDN high-performance grease)

Lubrication of bearings

Lithium-thickened grease,

and gearbox (also for

worked penetration 265-295

exposed gears)

(0.1mm), basic oil viscosity:

190 cSt (mm

2

/s) at 40° C,

drop point: 180° C,

Working temperatures:

- 20° C to + 120° C,

designation in accordance

with DIN 51825: KP2K-20,

active agents:

EP additives (for wear-

reduction) and ageing

protection; water resistant

and corrosion protection

Summary of Contents for JDN mini 1000

Page 47: ...powered by air NOTES Page 47 ...