The decisive factors for the type of operation are the

collective loads with different cubic averages

k .

The collective load indicates to what degree a driving

mechanism, or a part of one, is subjected to its maxi-

mum stress or only to smaller stresses. The cubic aver-

age (factor of the load spectrum) is calculated using the

following formula.

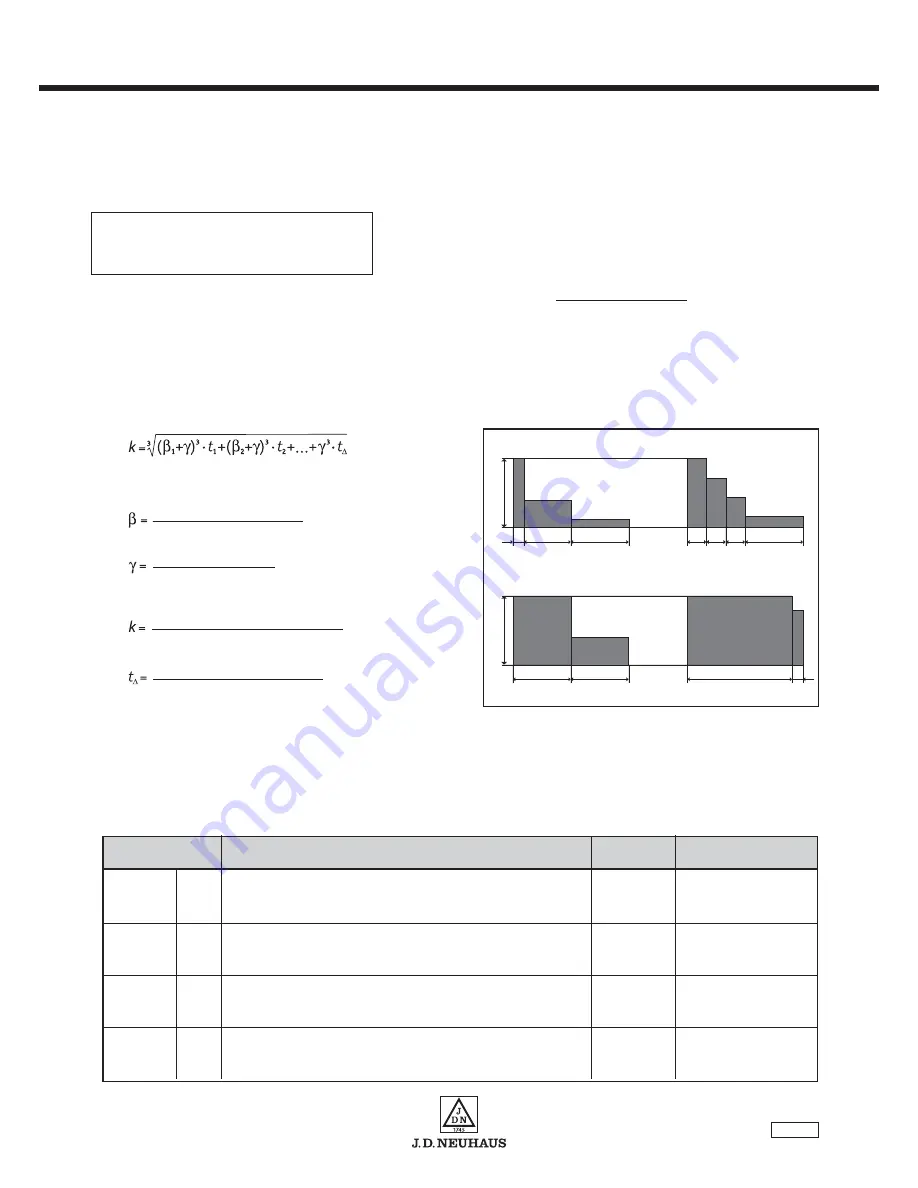

The FEM* 9.511 rule differentiates between four collec-

tive loads, which are identified by the definitions and

by the ranges of the cubic averages

k

. This classification

complies with ISO 4301/1.

*FEM = Federation Europeene de la Manutention (European Federation

of Materials Handling and Storage Equipment)

The formula given for the cubic average

k

does not take

the weight of the harness into account. This is permissi-

ble if the ratio

To determine the type of operation for calculating

the partial operating times (actual operating time),

the following collective load diagrams can also be used.

I N S T R U C T I O N S CO N C E R N I N G T H E

˝ M O D E L F O R D E T E R M I N I N G T H E

AC T UA L O P E R AT I N G T I M E

˝

powered by air !

M A I N T E N A NC E

Page 31

Weight of harness

Load-bearing capacity

≤

0.05

Maximum or ultimate load

Load-bearing capacity

Definitions:

=

Dead load

Load-bearing capacity

=

Operating time with maximum

load or partial load and dead load

Total operating time

=

Operating time with dead load

Total operating time

=

Collective load 1

Collective load 2

Load proportions

t

2

t

1

t

Δ

t

3

0.4

0.1

0.733

0.467

0.2

0 10

50

100

0

16.7 33.3

50

100

t

2

t

1

t

Δ

1

Collective load 3

Collective load 4

Load proportions

t

1

t

Δ

0.4

0.8

0

50

100

0

90 100

t

1

t

Δ

1

Collective load

Definition

Cubic

Collective load factor

average

1

L1

Driving mechanisms or parts thereof, which are only subject

k

≤

0.50

(low)

to the maximum stress in exceptional circumstances, and

are only subject to very lowstresses continuously.

2

L2

Driving mechanisms or parts thereof, which are subject to

0.50 <

k

(average)

the maximum stress often, and are only subject to low

≤

0.63

stresses continuously.

3

L3

Driving mechanisms or parts thereof, which are subject to

0.63 <

k

(high)

the maximum stress often, and are subject to average

≤

0.80

stresses continuously.

4

L4

Driving mechanisms or parts thereof, which are subject to

0.80 <

k

(very

the maximum stress of adjacent stresses regularly.

≤

1,00

high)

k

m

=

k

3

= 0.125

k

m

=

k

3

= 1

k

m

=

k

3

= 0.25

k

m

=

k

3

= 0.5

Summary of Contents for JDN mini 1000

Page 47: ...powered by air NOTES Page 47 ...