powered by air !

M A I N T E N A NC E

Page 32

Slewing

crane

assembly

site

1.5

0.25

1.5 x 0.25

x 250 x 1.2

= 113 hours

(400 - 113)

287 hours

2 August

2004

A.N. Other

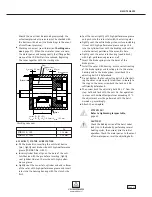

MODEL FOR DETERMINING THE ACTUAL OPER ATING TIME

The following calculation compares the actual operating time with the theoretical operating time

in collective load 4 (very heavy).

C ALCUL ATION MODEL (DRIVING MECHANISM CL ASSIFIC ATION M3)

Operating

site

Average

daily

operating

time

in hours

Collective load factor in accor-

dance withcollective load for

the type of operation

Partial deploy-

ment

Remaining

theoretical

use in

collective load 4

(When zero has been reached

a general overhaul must be

performed)

Date

Delivery

Initial

operation

Inspections

Specialist

inspector

Signature

1

2

3

4

5

6

7

L1

Low

L3

High

L4

Very

high

L2

Average

0

0.125

0.25

0.5

1

0

Existing driving mechanism

group, see nameplate

M2 (1Cm) 200 hours

M3 (1Bm) 400 hours

M4 (1Am) 800 hours

M5 (2m) 1600 hours

Delivery date

Initial

operation

Column 2

x column 3

x operating days

x factor 1.2

GmbH & Co.KG

–

Summary of Contents for JDN mini 1000

Page 47: ...powered by air NOTES Page 47 ...