powered by air !

M A I N T E N A NC E

Page 33

The specified inspection intervals are valid for use in accordance with the classification (see driving mechanism classifi-

cation on the nameplate). The service life is approx. 10 years if the device is used in accordance with its classification.

If the hoist is used more intensively the intervals are to be shortened accordingly. The intensity of use must be assessed

using the

model for determining the actual operating time

(see page 31). All operating hours are translated into full

load hours. The theoretical operating time and the interval hours are indicated in full load hours.

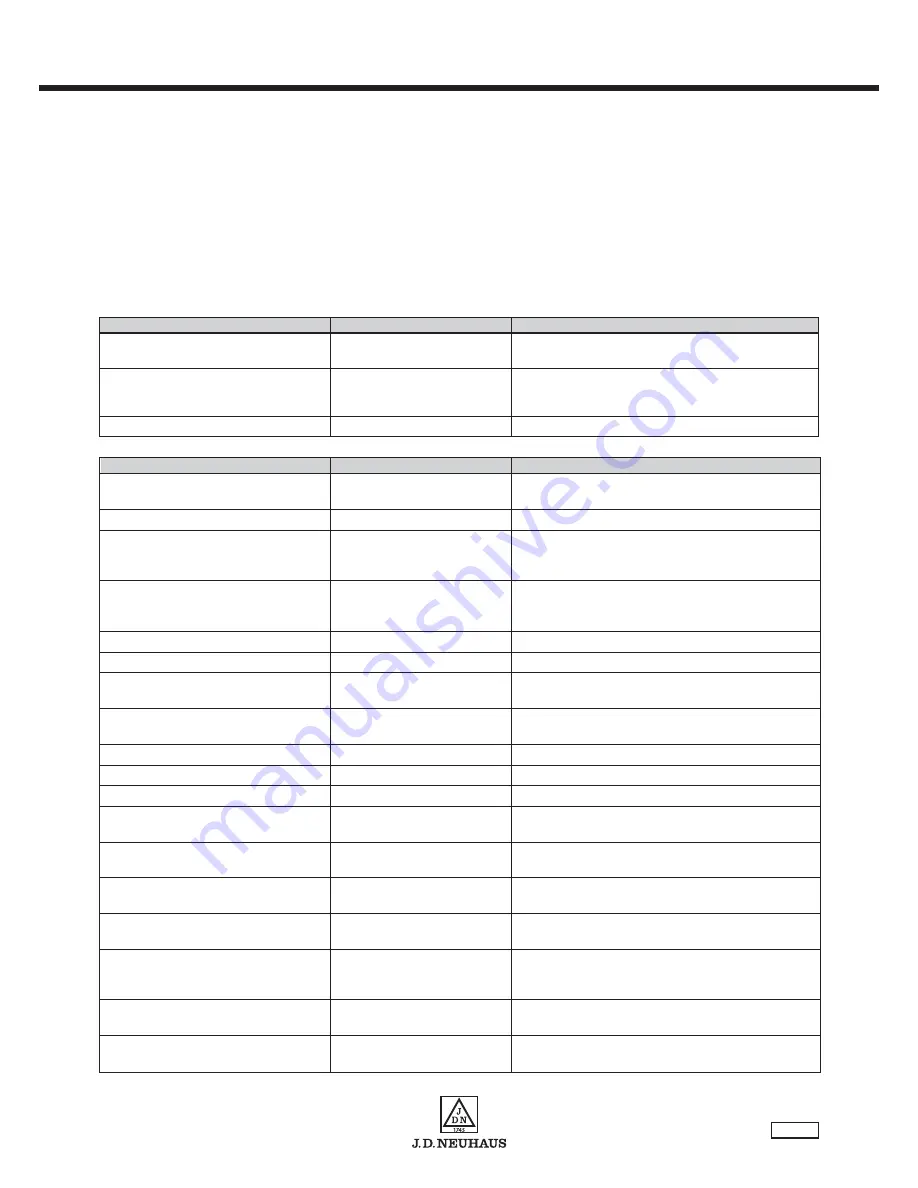

Maintenance measure

Interval

Comment

Check oil level

As required

see

Service unit operation manual

in the service unit

1

Lubricate chain

Monthly

Shorten inspection intervals in the case of

wear-promoting operating conditions

(Section

Lubricating the chain,

page 34)

Visually check the chain

Weekly

Inspection measure

Interval

Comment

Check control equipment

Daily

(Section

Checking controls and emergency

and EMERGENCY STOP device

stop,

page 35)

Check braking function

Daily

(Section

Checking braking function

, page 34)

Visually check lifting and

Daily

Replace buffer immediately if damaged,

lowering limiters (buffers)

otherwise replace at least once a year (Section

Checking lifting and lowering limiters,

page 34)

Check chain

Every 3 months

(Section

Checking chain

, page 39).

Shorten inspection intervals in the case of

wear-promoting operating conditions.

Check sprocket wheel and chain guides

Each time the chain is changed

Check all bolted and pin connections

Yearly

Check load hook on the load and

Yearly

(Section

Checking and replacing load hook and

carrying side

buffer,

page 38)

Checking axial movement of the

Yearly

Max. axial play of the load hook mount: 2.5 mm

load hook

(Section

Checking axial play

, page 38)

Check brake with load

Yearly

The load must be braked reliably

Check service unit

1

Yearly

See Service unit operation manual

Check silencer for permeability

Yearly

(Section

Checking silencer for permeability,

page 35)

Check compressed air connections

Yearly

for damage

Check motor, clean and

Yearly

Measure the lifting speed

grease control valve

Check condition of chain box

Yearly

Section

Chain box

, page 41

including mountings

Renew grease lubrication of motor

As required,

(Section

Installation/motor lubrication,

page 37)

At least every 5 years

Check brake wear and motor

Every 5 years

(Section

Replacing brake disc, brake piston and

vane wear

vanes/motor installation,

page 36), replace motor

vanes every 5 years

Check gearbox and perform

Every 5 years

lubricant change

Check shaft coupling and lubricate

Every 5 years

with gear grease

1

If fitted

Summary of Contents for JDN mini 1000

Page 47: ...powered by air NOTES Page 47 ...