The braking action is applied at the lateral surfaces of

the rotor. The rotor is pressed via spring force from the

cover side of the motor against a brake disc located on

the opposite side by means of a brake piston.

Remove the nameplate

1

.

Release the lock nuts

14

of the adjusting bolts

13

(4 screws).

Screw in the adjusting bolts

13

to the stop in the

cover; do not tighten.

Then screw back the adjusting bolts

13

45° from

the stop, hold and lock with the nuts

14

.

Attach the nameplate.

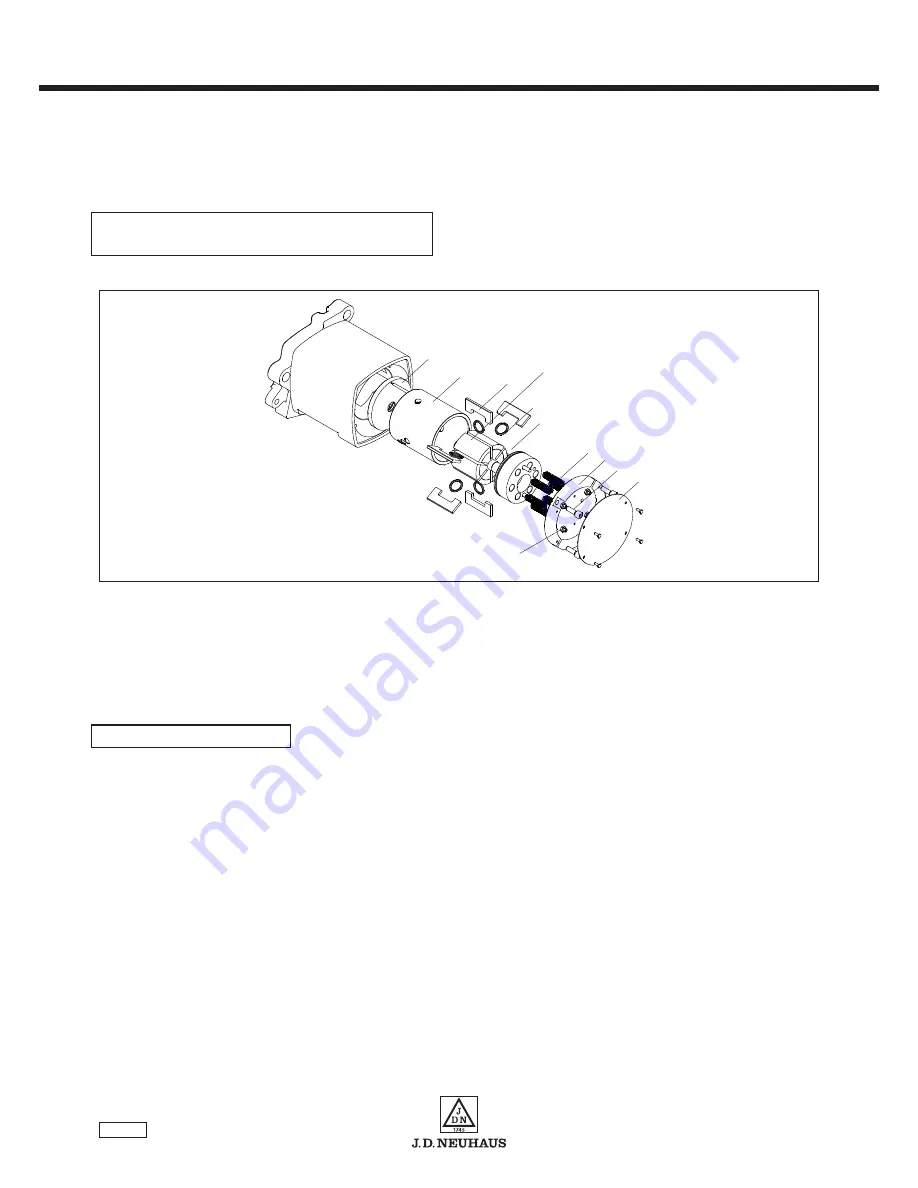

R E M O VA L

Proceed as follows when removing the brake disc and

brake piston:

Disconnect the hoist from the main air supply.

Unscrew the nameplate

1

.

Remove the cover bolts

2

behind the nameplate and

detach the cover

3

(when the cover bolts are removed,

the tension of the brake springs

4

is fully released).

Remove the springs

4

.

Remove the brake piston

7

from the cylinder liner

8

.

Pull out the rotor

9

, collecting the vanes

10

and

starting aids

11

.

N O T E

If you only wish to replace the vanes with the starting

aids, please continue with the section ˝Checking for

vane wear˝.

Pull out the cylinder liner

8

.

Remove the brake disc

12

.

Check the brake disc

12

and brake piston

7

for wear

and damage, replace if necessary. The circular wear

pattern must not be deeper than 0.2 mm.

The extremely low-wear braking material will not reach

the wear limit of 0.2 mm within the design-dependent

service life of the hoist, under intended use.

A D J U S T I N G T H E B R A K E

R E P L AC I N G B R A K E D I S C , B R A K E P I S T O N

A N D VA N E S / M O T O R I N S TA L L AT I O N

powered by air !

M A I N T E N A NC E

Page 36

Replacing brake discs, brake piston and vanes / Motor installation

12

8

10

9

11

7

4

3

2

1

13/14

Summary of Contents for JDN mini 1000

Page 47: ...powered by air NOTES Page 47 ...