AT T E N T I O N !

The chain supplied together with this JDN

hoist is matched to the chain sprocket

according to strict tolerances. In order to

ensure optimum function of the chain and in

order to prevent hazards, only genuine JDN

chains must be installed.

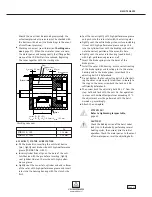

Align the new chain and check the correct number

of chain links. The chain must have an odd number of

chain links (feature: same position of end links). Allow

chain to run into the hoist using the insertion aid

1)

1

.

The welds

2

must face outwards (see illustration).

Installation of the load sleeve, clamp, buffers and

buffer discs is performed as per the description in the

section

Replacing load hook including load sleeve

and buffer,

page 39.

The replacement of the chain with a new one must

be entered into the inspection log.

1)

Art.-No. see spare parts list

In most types of application, a chain box makes a sig-

nificant contribution to operational safety. Only use

original JDN chain boxes on JDN Air Hoists.

Constructions from other sources may represent a high

safety risk. Rust on the chains increases the chance

that the chain may form large piles in the box

and is therefore not permissible.

Depending on the ratio of the size of the hoist (without

running gear) and the chain box, the chain box may

have to be stabilised by the customer due to an accept-

able vertical hoist position. This is facilitated by a sus-

pension point on the rear of the box. We will be happy

to answer any questions on this matter. Modifications

may only be made to the chain box on agreement with

J.D. Neuhaus GmbH & Co. KG.

The chain must only enter the container via the chain

drive. If it falls out of the container, e.g. during trans-

portation, it must be run out completely on the load

hook side and then run back into the container via the

chain drive, in the air hoist operating position.

DA N G E R !

If JDN Air Hoists are operated without a

chain box, it must be ensured that the

idle chain (unloaded chain end) running up

or down at the chain sprocket, does not pre-

sent a hazard, e.g. due to catching, impact-

ing or falling.Danger due to falling chain can

also arise if, when lifting, the idle chain is

first deposited on a load with a large surface

or other surfaces above the traffic level, then

slides off and drops.

AT T E N T I O N !

Do not exceed the permissible filling

capacity. Danger of chain falling.

DA N G E R !

When operated with a chain box, lubrication

of the chain is particularly important in

order to prevent it from piling up and falling

out. Do not install longer chains when

changing chains.

AT T E N T I O N !

Loads must not be moved against the chain

box when

lifting loads. If necessary, attach a clamp

with buffer and buffer discs to the chain.

The clamp with buffer and buffer discs must

be attached above the load hook so that it

functions as a preliminary end position lim-

iter (see section

Replacing chain and chain

sprocket,

page 40).

AT T E N T I O N !

Never allow the chain to pile up

in the chain box.

After installing the chain box, lower the load hook

to the bottom position once.

Then activate lifting movement and run the

complete chain into the chain box once.

If the hoist has been transported with the chain in the

chain box, the chain box must be emptied manually

before initial operation (if necessary, remove the chain

box from the hoist). The entire chain must then be

allowed to run to the load side and, subsequently, be

driven back into the chain box. The hoist must be kept

in a hanging position during this procedure. This

process will ensure that the chain does not lock when

loads are being lowered.

C H A I N B OX

powered by air !

M A I N T E N A NC E

Page 41

Summary of Contents for JDN mini 1000

Page 47: ...powered by air NOTES Page 47 ...