The basis for the following information is an expert

statement by the DMT Gas & Fire Division on the use

of JDN Hoists, Trolleys and Crane Systems in explosion-

hazardous areas, based upon European Guideline

94/9/EC

1

(˝ATEX 100a˝). DMT is accredited with the

testing of devices and protection systems for intended

use in explosion-hazardous areas.

MINI type JDN Air Hoists are category 3 devices for

general industrial use and for use in zone 2 for gases

of explosion group IIA. They are also suitable for use

in zone 22 for dusts, provided that no light metal or

other impact-sensitive dusts are present.

They are designated by

II 3 GD IIA T4(X)

A D D I T I O N A L M A R K I N G ˝ X ˝

This designation refers to explosion protection details

in the operation manual.

II 3 GD IIA T4(X):

This designation does not permit use in the presence of

light metal or other impact-sensitive dusts, or in the

presence of dusts with glow temperatures below 210° C

or ignition temperatures below 202° C. The permissible

ambient temperature range (Ta) extends from - 20° C to

+ 50° C.

M AT E R I A L S F O R F R I C T I O N A N D I M PAC T H A Z A R D S

Impacts between particular materials result in an

increased ignition hazard. This does not apply to

corrosion-resistant steel or cast iron against aluminium,

magnesium or corresponding alloys. It applies in partic-

ular to the presence of rust or of rust film. Rust (also

rust film) formation is possible, especially on the chain

and on the load hook, at the friction points. The follow-

ing holds true for all zones: For the intended use of

hoists it must be ensured that no rust is present at the

above-mentioned friction points and that material

combinations of the above-named light metals with

steel (exception being stainless steel) or cast iron are

not used in the working area of the hoists, at potential

friction, impact or sliding points.

It is thus possible to exclude sparking due to mechani-

cal influences with these material combinations.

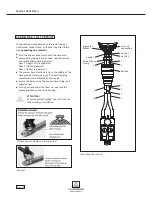

The external housing of the service units is made of

aluminium. Therefore the installation position is to be

selected so as to ensure that there is no risk from

impact sparks.

C L E A N I N G P L A S T I C S U R FAC E S

Where JDN Air Hoists or JDN Air Winches feature plastic

parts, these surfaces must only be cleaned using a damp

cloth (cleaning cloth with water). This reduces electro-

static charging that can arise due to mechanical friction

at the plastic surface.

DA N G E R !

Electrostatic charging may occur at the

plastic surfaces, potentially leading to

electrostatic discharge that can ignite

gases and air mixtures.

E X P L O S I O N P RO T E C T I O N

powered by air !

P RO D U C T I N F O R M AT I O N

Page 9

Summary of Contents for JDN mini 1000

Page 47: ...powered by air NOTES Page 47 ...