I N I T I A L O P E R AT I O N

Page 24

AT T E N T I O N !

The control hoses must not be subject

to tensile load; adjust the strain-relief

ropes accordingly.

Pull the bellows over the hose adapter and secure via

the central bolt, (see page 22, bottom).

C O N V E R S I O N F R O M E T O F I

Removal of E-controls as previously described (page 23).

Installation of FI-controls

Pull the bellows over the hose bundle for FI-control.

Remove approx. 80 mm of hose bundle protective

sheathing.

Screw the "straight screw connections" (Steck-fix) for

4 mm hoses into the hose adapter (A/F 16).

With this type of control, strain-relief of the hand

controls is via the protective sleeve of the hose bundle.

For this purpose, the protective sleeve is pushed onto

the hose carrier and is secured using a one-ear clamp.

Installation facilitation:

Heat the protective sleeve

(hose sheathing) with a hot-air gun and grease the

hose carrier.

Slightly bend open the ring of the eye bolt in order

to attach the hose carrier.

Close the ring again to prevent detaching.

Insert the control hoses:

See illustration on page 22, top.

Compressed air

with hose designation 1 or colour: white

Movement direction "lift"

hose designation 2 or colour: green

Movement direction "lower"

hose designation 3 or colour: red

AT T E N T I O N !

The control hoses must not be subject to

tensile load; adjust the strain-relief

ropes accordingly.

Pull the bellows over the hose adapter and secure via

the central bolt, (see illustration on page 22, bottom).

CONVERSION FROM AIR CONTROL TO ROPE CONTROL

AT T E N T I O N !

Only air controls without upstream mainstream

valve can be converted to rope control.

Removal of air controls

Remove the hose adapter (secured by central bolt).

For removal of the hose adapter, a long A/F 6 socket

spanner must be guided through the middle of the bel-

lows and inserted into the hexagon socket of the bolt,

(illustration on page 22, below).

The cover

"1"

in the axis centre must be removed

(M 6 bolt, A/F 5).

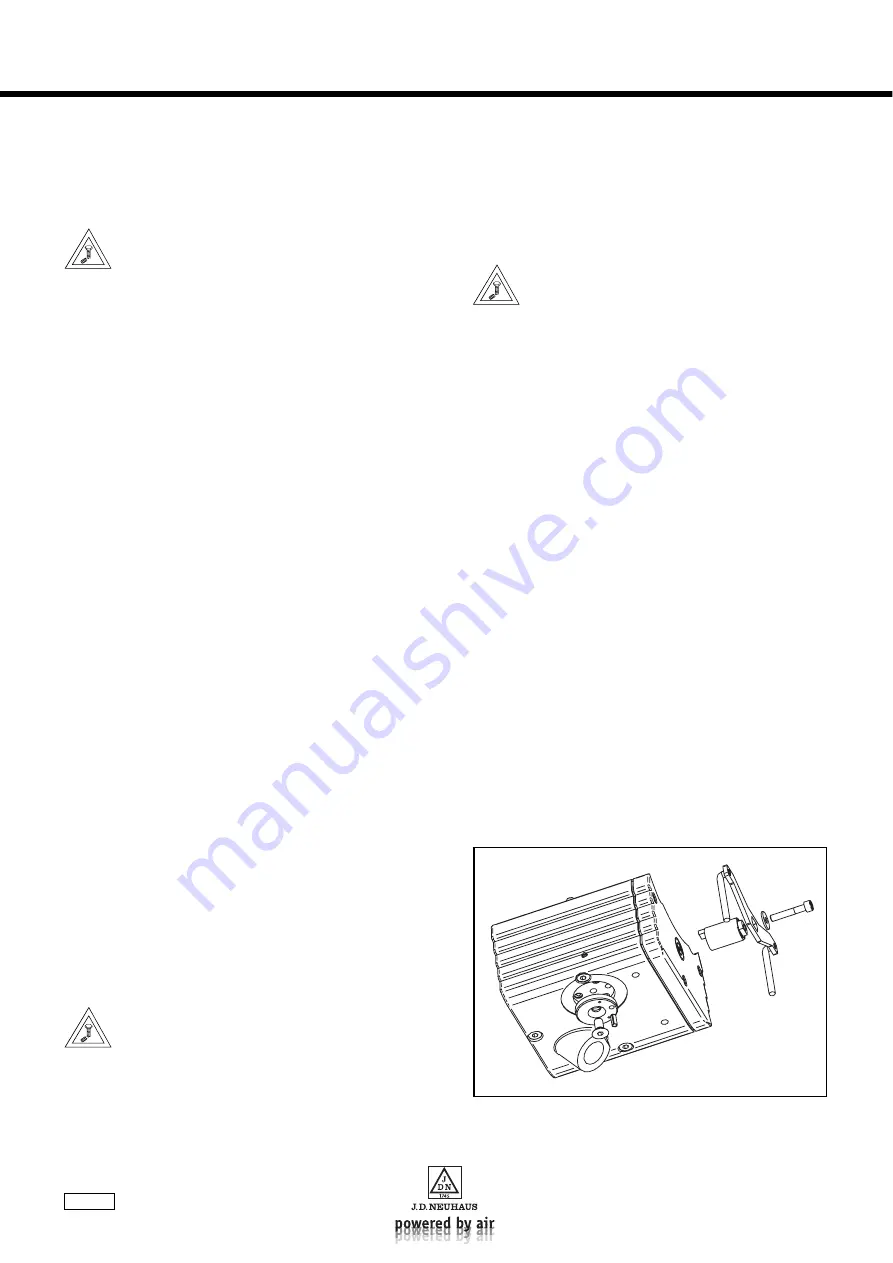

Installation of rope controls

The connecting surface of the hose adapter on the valve

housing is closed off with a disc, (from conversion kit

Art. no.: 13590, item 10) and is secured with the

M 8 x 16 countersunk screw (item 50).

The dowel pin (roll pin, item 70) must be inserted in

the bore

"2"

provided.

Insert the rope control lever connector (item 20) into

the cover bore with the lug

"3"

facing upwards; push

on the control lever (item 30) and secure with the

M6 x 35 bolt (item 40) and washer (item 60).

Guide the control ropes

"4"

through the bores

"5"

in

the lever and knot them. Rope colour: "green" lift,

"red" lower. Further, see section

Connecting the rope

controls

, page 20.

Installation of rope controls